This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

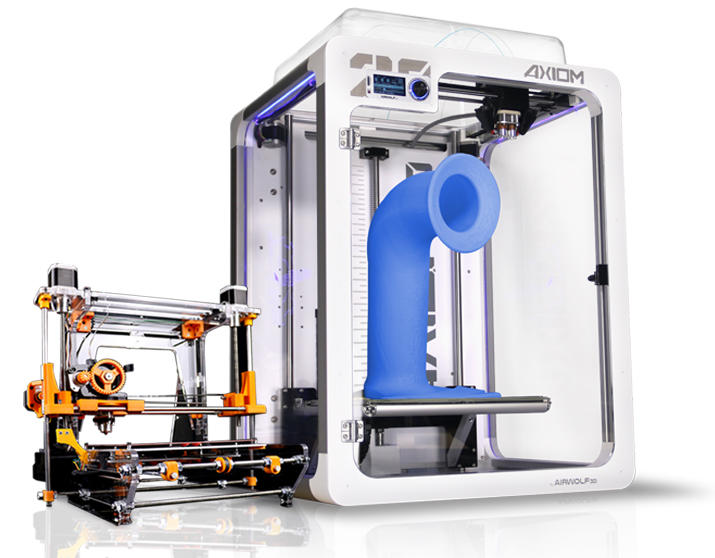

Erick Wolf is the co-founder and chairman of Airwolf 3D. Based in Southern California Airwolf 3D design easy-to-use 3D printers that are not only accurate, but also capable of incredibly fast print speeds. The company’s goal and mission is simple, “make and sell a superior desktop 3D printer.”

3D Printing The Next Five Years by Erick Wolf, Airwolf 3D Co-Founder/Chairman

The Rise, Fall and Comeback of 3D Printing

When 3D printing exploded into mainstream culture in 2011, many pegged their hopes on the intriguing new technology. By 2013, investors bullishly hopped on the trend, driving 3D printing stocks to a new and frenzied apex. New, less expensive desktop 3D printers largely drove the hype, touting an irresistible promise of easy-to-use 3D printers that quickly produced flawless, high-resolution parts. Visions abounded of a world where 3D printing will democratize manufacturing and even average consumers can save time and money by simply printing whatever they needed. That obviously wasn’t the reality.

Consumers learned a hard truth about desktop 3D printers: clogs, jams and malfunctions were common and a relatively steep learning curve was required to even get the machine to work at all. In short, the technology was awkward and premature.

And the market responded in kind. It’s only now that the industry has begun to pull out of the nosedive caused by the gross disparity between the expectations and reality garnered in the early days of desktop 3D printing.

The good news is that we have entered a new era, a period of time when we not only possess a deeper understanding of how our customers use 3D printing, but we also are innovating and improving software and hardware at a rapid pace. Expectations are being recalibrated and the industry can focus on what we do best and what we need, most urgently, to accomplish.

Moving Forward by Going Back to Basics

If history repeats itself, you will discover that the earliest champions of 3D printing were absolutely correct in declaring that 3D printing will be ubiquitous someday. Virtually everyone will have a 3D printer and, like personal computing and smartphones, the technology will be fully integrated into everyday life. It will just take longer than so many had hoped.

In the larger scheme of manufacturing techniques, 3D printing is easy to use – even my 9-year-old can run a 3D printer (and, yes, 3D-printed fidget spinners are a common sight in our household). The fact is that humans are pretty lazy creatures. Ultimately, it is in our nature to find solutions that offer the path of least resistance – like 3D printing.

A new generation of industrialists will realize that they can accomplish many fundamental tasks – such as prototyping, tooling, and even creating actual production-grade parts – more easily with 3D printing. And as that understanding takes hold, 3D printing will gain solid traction and widespread adoption.

To understand how 3D printing will evolve into a primary manufacturing technique, it is helpful to look at China’s industrial history. Many have postulated on the reason why China never experienced an industrial revolution equivalent to the ones that occurred in the western world in the 18th century. A leading theory is that China simply had no need for explosive technological growth because the country’s immense number of people provided the manpower required to manually operate their existing machinery.

For example, in the 18th century, the Hua-Lou district of China had the labor force to manually run machines used for irrigation and pressing oil. In contrast, the Netherlands had comparable manufacturing activities to China at that time, but did not have the same level of manpower. As a result, Dutch entrepreneurs invented the windmill in response to the need for increased output through more sophisticated, automated technologies. The same result was seen when it came to printing. While the Chinese utilized manually intensive woodblock printing for centuries, Europeans developed moveable type much sooner in order to achieve mass communication more effectively.

We will see a similar phenomenon unfold with the evolution of standard manufacturing processes in the United States. Our country is facing a growing shortage of skilled laborers, especially in the manufacturing sector. With less workers who know how to operate equipment like CNC machines, injection molding machines and laser cutters, American manufacturing eventually will have to turn to a more sophisticated, automated technology that increases productivity without requiring an increase in human labor. That technology is 3D printing.

The Next Five Years and Beyond

Over the next five years, we will continue to watch the shift towards true, widespread adoption of 3D printing. This is an incredibly exciting time because we will see some of our era’s great innovators and trailblazers emerge and apply 3D printing in ways that will set the foundation for the future.

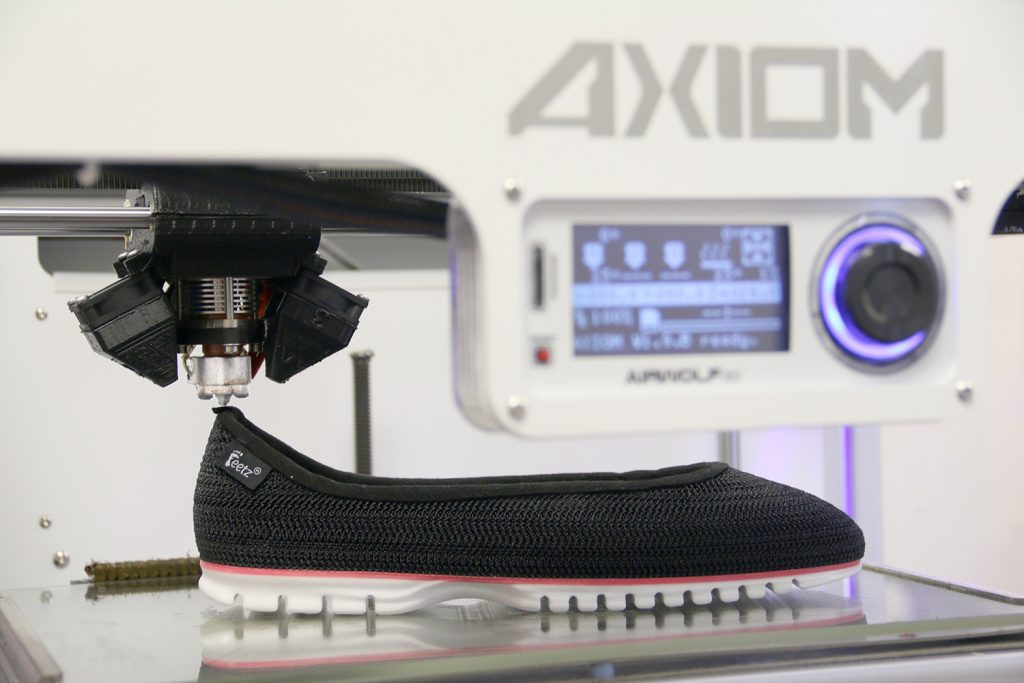

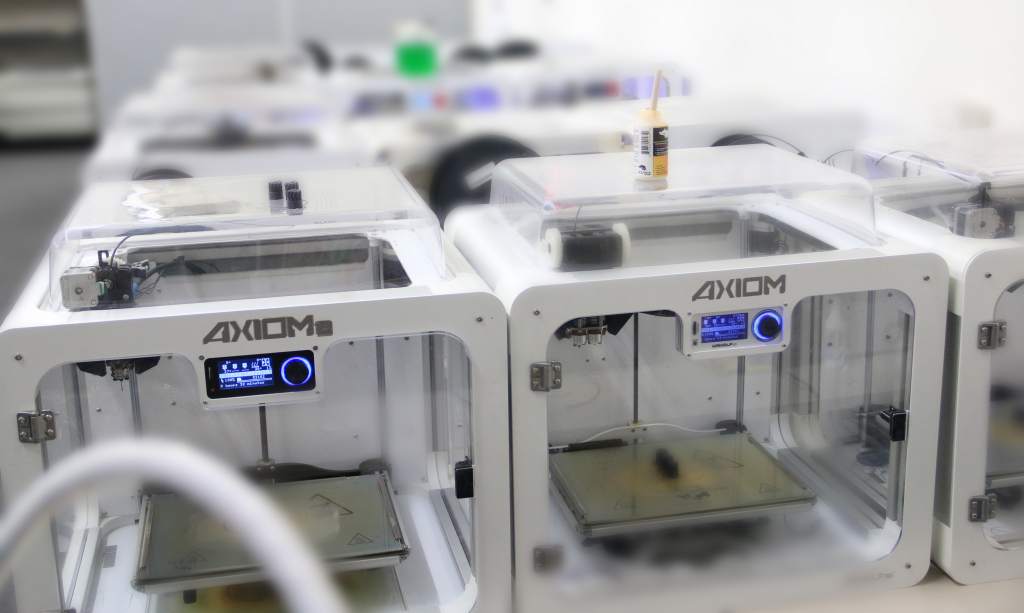

These visionaries will be those who have no preconceived notions about manufacturing, but instead leverage the convenience and cost-savings of 3D printing to create a profitable business model. Such innovators will follow in the footsteps of early adopters like Feetz, a self-described “digital cobbler” who maintains an army of continuously running AXIOM 3D printers that are used to mass customize shoes.

You also can expect to see continued growth of on-demand 3D printing services like 3D Hubs, Voodoo Manufacturing, and Access3D Services.

Ultimately, 3D printing will fulfil the promises that catapulted it into mainstream awareness back in 2011. At the end of the day, the technology will gain widespread adoption simply because it is easier to use than traditional manufacturing techniques. Best of all, 3D printing will only become even easier to use as we surge ahead with continuous improvements to quality, performance, and speed.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information.

For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about Airwolf 3D is available here.