Arguably one of the most interesting fields in the 3D printing industry is the development of the materials for use on 3D printers, both from the business perspective as well as looking into material attributes and properties to find new ways of using them in the manufacturing process. Today we are focusing on the latter and in particular the use of Nylon with entry level 3D printers.

Typically, users of entry-level 3D printers have had to choose between two commonly available materials — PLA or ABS filament. Taulman, reknowned for his expertise in building his own Instructables 3D printer and his knowledge of plastics, has been experimenting with Nylon for some time now – and with credible success.

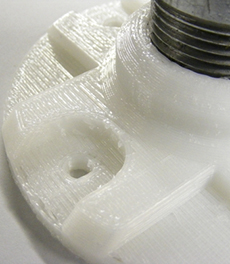

The main difference when using Nylon is that there is almost no de-lamination. The bonding of thread-to-thread is comparatively higher than with ABS or PLA, despite the parts being subject to splitting at right angle transitions. According to Taulman the results for using injection moulded Nylon for 3D printing are “impressive”. The polyamide materials give off almost no odour and some water vapour during printing and you can print the material in high resolution as usual.

Taulman’s results also point out that key properties such as strength yield advantages over ABS/PLA as well as the end result being lighter and more pliable in use. He commented: “From stretch in bands, to elasticity in support components, pliability means that multi-part assemblies are more likely to work as designed with minimal filing, cutting and sanding. Nylon springs can be completely compressed and return to a printed state. Hollow tubes are possible, when needed to guide gasses through complicated assemblies”.

You can also make your object in any colour you like as Nylon is easily dyed with standard textile and paper acid dyes, for which he also provides hands on instructions on his website. The Taulman list of positive experiences and properties with Nylon goes on and is supported by the maker community following his lead.

Having worked out the challenges with high temperature plastics, his next foray is doing the same with Delrin and transparent Polycarbonate. This is promising for everyone looking to have a choice of materials for their future 3D printers.

Below is a brief demonstration of a “T” support being subjected to an 8lb sledge hammer impact test.