EOS, a technology and market leader for design-driven additive manufacturing solutions, introduced a number of new developments at Euromold last week, including hardware, process management, materials and applications.

As a supplier of industrial grade 3D printers for manufacturing and prototyping, EOS works closely with a number of partner companies as well as customers to drive 3D printing across various vertical sectors, which includes consumer products. To this end the company operates according to the maxims: innovation, quality and sustainable solutions.

At Euromold, EOS unveiled the FORMIGA P 110 3D printer, the successor of the extremely successful entry-level system FORMIGA P 100 and the EOSINT M 280, the latest metal laser sintering (LS) platform. There was also an update on the PRECIOUS M 080, which is scheduled for commercial release by the middle of next year. The PRECIOUS M 080 is a compact LS system developed specifically to process precious metal parts made of 18 carat yellow gold and it represents an economical production solution for the jewellery and watch industries.

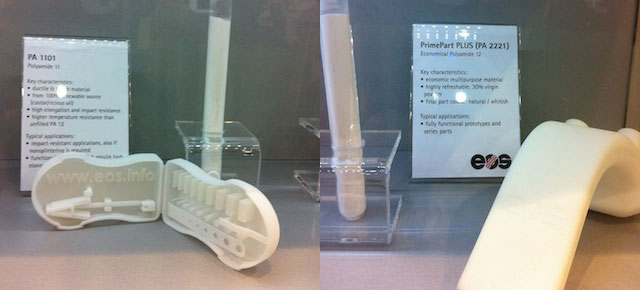

EOS also introduced two new plastic materials — Prime Part PLUS and PA 1101.

PrimePart PLUS represents a breakthrough in polymer development as the material can be refreshed using only a 30% share of new powder, resulting in a powder cycle with minimum scrap quantities. This improves the cost efficiency and sustainability of the laser-sintering process, since conventional laser-sintering materials are usually refreshed using 50%+ new powder. Technical performance of the material is unaffected.

The PA 1101 material is a natural-coloured polyamide 11, which is characterized by high elongation at break and impact resistance with a balanced performance profile. The material is based on renewable resources and therefore classified positively in environmental terms. On account of its properties, the material is particularly suitable for applications with functional elements that require high material ductility and high impact resistance.

According to Peter Klink, EVP Sales at EOS: “With these two new materials, EOS is extending its range of plastic materials clearly towards ecology, technical performance and low manufacturing costs, allowing standard components to be manufactured even more efficiently using laser-sintering.”