Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

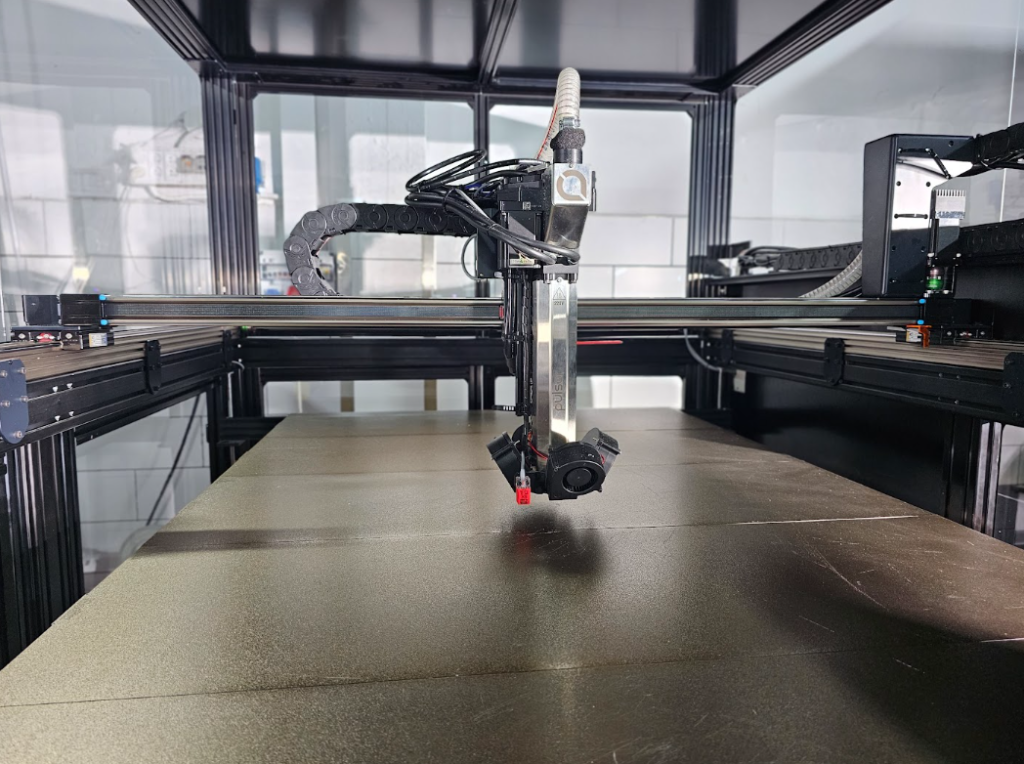

Large format 3D printer manufacturer Modix has launched the MAMA-1700 and a new line of FGF (Fused Granulate Fabrication) 3D printers, ahead of its 10th anniversary in the AM sector.

The new MAMA line, featuring the MAMA-1700, is designed to meet the needs of various industries, including marine and aviation. Priced at $47,000 (introductory price $42,000 + shipping), it supports applications such as molds and final products, making it a versatile choice for various industrial uses.

Available as self-assembly kits, these printers ensure flexibility and convenience for users. Modix’s network of 50 specialized resellers worldwide provides local assembly and support, enhancing the accessibility and service for customers.

Notably, the MAMA-1700 is the first printer in the line to utilize FGF technology. Pre-orders for the MAMA-1700 begin in early July, with production slated for August and deliveries expected in Q4-2024.

Shachar Gafni, CEO of Modix, said, “Modix is making a significant leap forward by introducing this new line of printers, enhancing our technological offerings and competitive position. We anticipate announcing more exciting developments later this year as a result of our dedicated R&D efforts.”

A high-throughput 3D printing system

As per Modix, Fused Granulate Fabrication (FGF) is an emerging 3D printing technology that utilizes pellets as a feedstock, offering an alternative to filament-based methods. This technology demonstrates the potential for increased print speeds, allowing the production of larger objects in shorter timeframes. Compared to traditional methods, FGF can potentially reduce printing costs and broaden the range of usable materials, including recycled materials and those with high-density fillers.

The MAMA 1700 offers a high flow rate, delivering up to 500 mm³/s. This capability supports the printing of large-scale objects at speeds of up to 3 kgs per hour, making it suitable for a variety of industrial applications. In terms of material versatility, the MAMA 1700 supports a wide range of materials, including PLA, ABS, TPE, TPU, PVA, HIPS, PC, PET, and Nylon. It also accommodates composites such as wood, glass fiber, and carbon fiber-filled materials, as well as recycled materials, enhancing sustainability efforts.

Precision engineering is a key feature of the MAMA 1700, ensuring consistent and reliable extrusion. This is crucial for maintaining the quality and accuracy required in industrial applications. The MAMA 1700 is designed for easy maintenance, which helps reduce downtime and operational costs.

Additionally, the Dyze Design’s Pulsar extruder offers a selection of nozzles ranging from 1mm to 5mm in diameter and various screws to meet different pellet 3D printing needs. This flexibility allows users to customize their printing process to match specific project requirements.

Technical specifications of MAMA 1700 3D printer

| Print Volume | 1.7 x 1.0 x 1.0 meters (XYZ) |

| Printer Dimensions | 2.1 x 1.53 x 2.35 meters (XYZ) |

| Enclosure | Included |

| Print Head | Dyze Design Pulsar |

| Flow Rate | 500 mm³/s, up to 3 KG/hour |

| Nozzles | 3mm and 5mm; 1mm nozzle is available as an add-on |

| Material Compatibility | PLA, ABS, TPE, TPU, PVA, HIPS, PC, PET, Nylon, glass & carbon fiber filled, and recycled options |

| Required | Air compressor (not included) |

| Motion system | Closed loop nema23 |

| Electronic controller | Duet 6HC |

| Optional Add-Ons | Air filter, additional nozzles, and more |

| Future Add-Ons | IDEX with pellets or filament |

| Delivery | Self-assembly kit. If assistance is needed, Modix can introduce the customer to one of its local resellers. |

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows Modix’s new MAMA 1700 FGF 3D printer. Photo via Modix.