Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

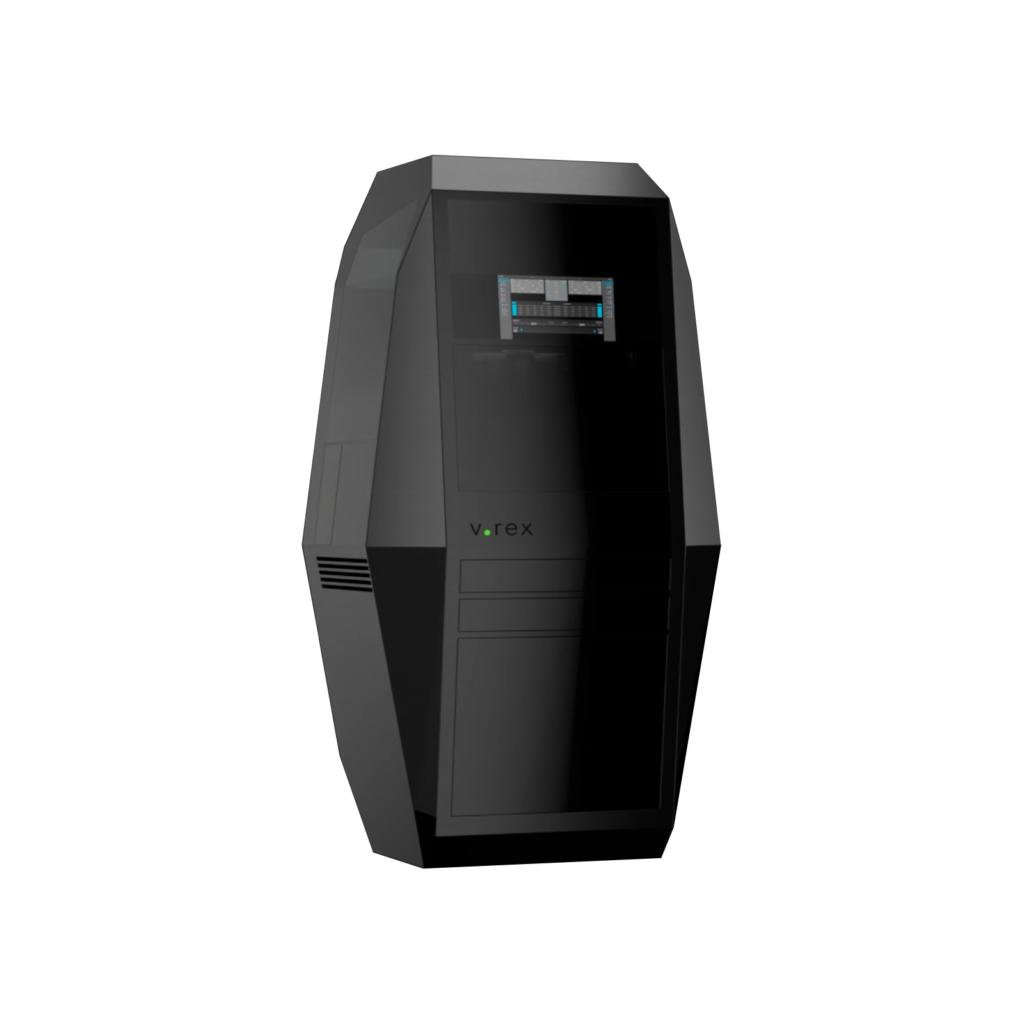

Austrian AM startup VENOX has launched its V-REX composite 3D printer, designed to meet the demanding needs of industrial and R&D sectors.

According to the company, ‘V-REX’ is an abbreviation for ‘VENOX Revolutionary Extrusion System.’ VENOX began working on the V-REX in 2022, drawing on the extensive experience of Co-founder Philipp Ropele, a veteran in the additive manufacturing field since 2016.

Supported by Austria Wirtschaftsservice (aws), the V-REX project was funded through the PreSeed DeepTech grant. Intended to support companies facing major technological challenges, this grant was earmarked for developing the 5-axis continuous fiber print head. This financial assistance is part of aws’ comprehensive effort to maintain Austria’s technological edge and help Austrian innovators break into international markets, says the company.

A versatile 3D printer with continuous fiber and multi-material capabilities

Equipped with a 5-axis printing system, the V-REX is optimized for continuous fiber materials. This enables the precise alignment of fibers like carbon along their natural direction, leveraging their anisotropic properties to create high-performance components.

In addition, the printer’s automatic tool changer can handle up to six different print heads within a single operation. This functionality significantly enhances the complexity and detail of manufactured components, rendering the V-REX a versatile instrument for engineers.

With specifications including a 5-axis travel path (X, Y, Z, A, C) of 600, 400, and 500 mm, and a 3-axis print volume (X, Y, Z) of 600, 400, and 400 mm, the V-REX is a versatile system says the company. It features an automatic tool-changing system that can support up to six tools in one process. Suitable for continuous fibers and thermoplastics, the printheads can heat up to 500 °C, thus accommodating a broad range of materials.

Established in 2022, VENOX specializes in 3D printing to create high-strength parts with various materials and integrated electronics. The startup’s approach allows for seamless integration of sensors and conductors during production.

VENOX also offers a modular system for making functional, lightweight, and strong components. This technology combines additive and subtractive manufacturing, using continuous fibers, metals, and high-performance polymers, even combining them in a single build.

Technical specifications of V-REX 3D printer

| 3 axis – print volume (X, Y, Z) | 600 | 400 | 400mm |

| 5 axis travel (X, Y, Z, A, C) | 600 | 400 | 500mm; A: +180-180° | C: 360° |

| 5 axis – component size | Temperature up to 500°C – water-cooled |

| Automatic tool changing system | Up to 6 tools for one process |

| Printing plate temperature | Up to 200°C |

| Installation space temperature | Up to 100°C |

| Print head for continuous fibers | Temperature up to 500°C – water cooled |

| Printheads for thermoplastic filaments | Various variants – temperature up to 500°C – water-cooled |

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows the V-REX 3D printer. Image via VENOX.