Effective tissue engineering is something of a holy grail in the 3D printing world. A new paper has looked at Selective Laser Sintering and inkjet 3D printing (3DP) of powder-based materials in a bid to produce biocompatible implants and scaffolds.

While researches have used both techniques on many occasions, 3D printing as a whole has come on in leaps and bounds. Recent advances in mass manufacturing, then, could have an impact on their ability to fabricate tissues and biological scaffolds.

A study has been published by the National Institute for Materials Science that doesn’t really clarify the issue. It does show just how big the task ahead really is, though. The study simple focuses on developing new biocompatible and bioactive materials, rather than advanced tissue construction. It shows we have a mountain to climb before we get the ‘best’ technique.

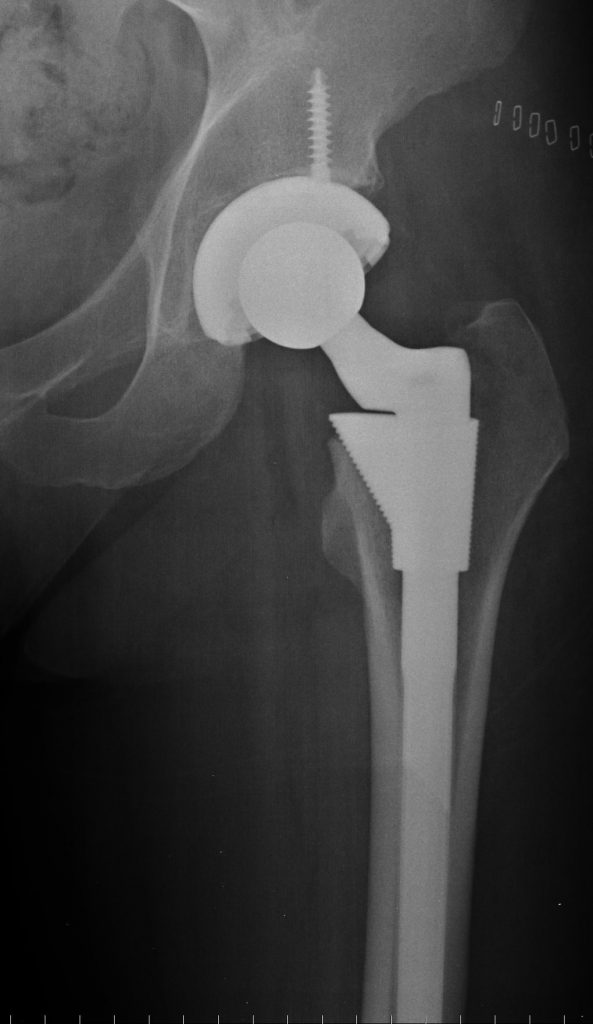

Scaffolds, in particular, offer ways to repair damaged tissues and can present a biodegradable structure that allows tissue and even cartilage to regrow around and through the structure. This is not new, bioglass has been with us since the late 60s. 3D printing, though, has the potential to revolutionise it and give us replacement cartilage and lumbar discs.

Which technique is best?

Inkjet 3DP and SLS are two commonly used powder-based tools in biomedical engineering applications. SLS comes with some inherent disadvantages at the moment, including a lack of fine control over the mechanical properties of the finished item, the inability to include hydrogels and the fact that the finished parts cannot be vascularised. Poor resolution in SLS is also an issue.

Inkjet printing offers better definition and porous architecture, but there’s a payoff in that the binder still presents a problem and many current options are simply toxic. Parts often require post-processing, too, including sintering. This can cause non-uniform deformation and shrinkage, which creates problems in real world applications.

Loose powder can also remain at the core with both methods and we actually don’t know the best materials for real tissue growth. Most of the studies so far have used in vitro results and only a few real implants have been produced with printed bone. In those instances, the surgeons and consultants erred on the side of caution.

Every choice comes with a bill

So there are complex equations we need to address with each form of 3D printing and massive amounts of testing ahead. In SLS, bed temperature, laser strength and duration is just the start. Tan et al determined the ideal bed temperature was 284 degrees Farenheit, but even this can be fluid depending on the material and desired result.

Solid state, liquid and full melting processes will all affect the quality of the finished product and the potential of biological scaffolds and structures to take hold and support life. Then we get to the material science, with polymers, ceramics, metals and even complex compounds that we have yet to discover all having a potential impact. Studies have shown encouraging results with SLS-produced Nylon, but there are so many permutations that it’s hard to say it’s the best possible material.

It’s the same with inkjet printing. We can choose between piezoelectric and thermal heads that can print a number of different polymers and ceramic compounds. The binder is critical, though, and must have the right level of viscosity, surface tension and concentration to create the mechanical properties required.

Serious testing lies ahead

It’s a bewildering and complex set of equations that will keep research teams busy for years. Computer learning will almost certainly have to play a part and even then it will not provide a complete assessment.

We need volunteers to undergo risky surgery and observe the results over time to be absolutely sure of the best strategy. So even though we’re breaking new ground every day and we’re at the start of a new dawn of medical technology, we still have a long way to go.