Ahead of the inaugural online event Additive Manufacturing Advantage: Aerospace, Space, and Defense 3D Printing Industry is running a series of articles focused on the application of 3D printing in these critical sectors. Register now for AMAA 2024 on July 16th to hear more insights from sector leaders.

TCT 3Sixty 2024 opened with a keynote from Digby Gill, the British Army’s Head of Advanced Manufacturing (AdM) Capability Coherence. Titled Additive Manufacturing for UK Defence, his talk focused on the British Army’s use of 3D printing for the production of mission-critical parts near the front lines.

He outlined how the British Army has integrated additive manufacturing into its operational workflow, and highlighted the critical challenge that must be overcome to increase adoption in the defense sector.

Additionally, Gill shared his thoughts on the future of 3D printing for defense, arguing that additive manufacturing “clearly has a large part to play in the future of military capabilities.”

Read all the news from TCT 3Sixty 2024

What problems does 3D printing solve for defense?

According to Gill, the British Army has witnessed a growing reliance on commercial suppliers to meet supply and production demands. He argued that the British Army has “lost touch with its ability to solve its own problems.”

Gill believes additive manufacturing is the perfect technology to reverse these problems and rebuild the Army’s manufacturing capabilities. In particular, he argued that deployable 3D printing technology can overcome prevalent issues related to insecure supply chains and long lead times.

Over recent years, threats have emerged that jeopardize the supply of international goods. These include COVID-19 pandemic, conflict in Ukraine, attacks on shipping in the Red Sea and Gulf of Aden, and geopolitical tension in the Taiwan Strait and South China Sea. This poses challenges for defense forces that often require mission-critical spare parts at short notice.

Gill argued that, rather than waiting weeks for the supply chain to deliver components, 3D printing can be used to produce critical spare parts when and where they are needed. This would enable military forces to get more equipment back in the fight.

He also highlighted issues of obsolescence. Many of the original manufacturers of the Army’s hardware either don’t exist or are unable to meet production demands. 3D printing is well suited to solve this problem, thanks to its ability to fabricate spare parts from scratch and to specific design specifications.

The British Army’s 3D printing capabilities

The British Army has been exploring the capabilities of additive manufacturing for the past five years. Gill explained that the Army possesses polymer 3D printing capabilities that have developed from a “hobbyist level” to the production of functional parts.

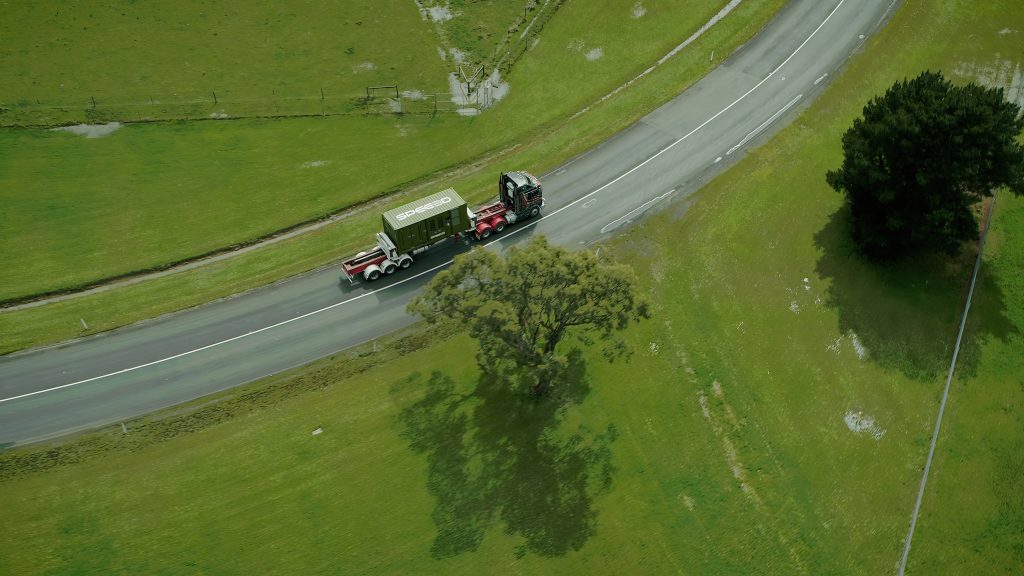

On the metals side, the British Army leverages technology from Australian 3D printer manufacturer SPEE3D. Having purchased its first XSPEE3D cold spray 3D printer in 2023, the British Army recently adopted the company’s new Expeditionary Manufacturing Unit (EMU).

The EMU combines the XSPEE3D, which can 3D print fully-dense metal parts measuring ⌀0.9m x 0.7m, with the SPEE3Dcell post-processing unit.

These two systems are built inside metal containers, allowing them to be placed on the back of a truck and transported anywhere in the field. This aligns with the British Army’s goal of operating 3D printers “as close to the frontline as possible,” explained Gill.

Unlike other metal 3D printers, SPEE3D’s cold spray technology does not use inert gasses or delicate lasers that can be easily damaged in transit. Instead, it fabricates metal parts by firing metal powder at a substrate at supersonic speeds. This makes SPEE3D’s technology inherently rugged, and ideal for deployment to active military environments.

Moreover, SPEE3D’s TwinSPEE3D software is designed to be intuitive, automatically processing 3D print files and generating optimal tool paths.

This is critical for the British Army, which requires the average soldier to operate its 3D printers. Gill explained that “3D printing is not a trade in the Army, and it’s not anyone’s full-time job,” meaning the technology needs to be straightforward and easy to use.

Gill also identified the ongoing development of the British Army’s digital repository, which is being used to store all of its 3D printable designs. This database ensures the production of “repeatable parts” by standardizing the additive manufacturing process throughout the Army.

3D printing excels in military trials

The British Army’s adoption of the EMU is part of a two-year experiment exploring whether it can “design, print, post-process, and assure metal parts” near the front lines and “on the move.”

As part of this initiative, the British Army recently began 3D printing spare parts in the field for the first time at Exercise Steadfast Defender, NATO’s largest military exercise since the Cold War.

Using its XSPEE3D, personnel from 9 Theatre Support Battalion, Royal Electrical and Mechanical Engineers (9 REME), have 3D printed replacement parts for old vehicles. These include caps for jerry cans, brackets for communications systems, and mounts found inside engine bays.

Gill also pointed to a bilateral agreement which has seen the British Army leverage additive manufacturing to support the Ukraine armed forces’ ongoing war efforts against Russia.

During AM Village 2024, a European Defence Agency event held in Belgium last month, British forces created technical data packs (TDPs) for 70 different spare parts. TDPs include the digital engineering information needed to 3D print the components. The goal was to provide Ukrainian troops with the means to produce critical spare parts with additive manufacturing.

Ukraine can now use the TDPs to manufacture the parts using its arsenal of industrial 3D printers. This includes WarpSPEE3D cold spray systems from SPEE3D and High-Speed Extrusion (HSE) 3D printers from 3D printer manufacturer Essentium.

According to Gill, the four-day project also saw the British Army 3D print 133 functional parts, 20 of which were metal. Gill views AM Village 2024 as a success, characterizing the event as “an amazing collaboration with our European allies” which resulted in “great support to Ukraine.”

The future of 3D printing in the British Army

Gill believes that challenges still need to be overcome before 3D printing can be more widely adopted for defense applications.

“We’re still trying to find out what AdM looks like in the Army,” explained Gill. “Although that’s come a long way, it still needs to go further.”

He pointed to limitations in training and personnel, arguing that the “technologies have progressed quicker than our abilities to make a syllabus.” Looking ahead, Gill envisions a dedicated school and training program that will filter out those who are well suited to additive manufacturing.

Increasing technical specialization in the British Army, especially concerning computer-aided design (CAD) and materials science, will allow AdM to become “a really impactful” technology for defense.

Register now for AMAA 2024 to hear insights from industry experts on additive manufacturing in aerospace, space, and defense.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.