Binder jetting 3D printer manufacturer ExOne has partnered with the on-demand manufacturing service Xometry to provide 3D metal printing services through its Digital RFQ Marketplace.

The deal will see ExOne become the exclusive provider of binder jetting services on Xometry’s platform, including those for metals, ceramics, sand and composite materials. Through the arrangement, Xometry’s customers will now be able to 3D print complex prototype parts using a variety of new durable metals and composites.

”We’re excited to offer binder jetting to expand the range of services our customers can get from Xometry’s new Digital RFQ Marketplace,” said Randy Altschuler, CEO at Xometry. “ExOne is a true innovator in additive manufacturing and we believe this partnership is a big win for our customers.”

Xometry in the 3D printing industry

Founded in 2013 and based in Maryland, Xometry is America’s largest online marketplace for custom manufacturing solutions. The company which has around 4,000 manufacturing partners across 46 U.S states, has managed to raise $113 million in investment since it was established.

Xometry is known for its Instant Quoting Engine, which uses machine learning to analyze the geometrical structure of uploaded parts, and addresses potential problems in their design. The algorithm ultimately is capable of providing quotes for a range of on-demand manufacturing processes including CNC machining, 3D printing, sheet metal and urethane casting.

The company has worked with a diverse range of companies from startups to multinational firms such as NASA and Bosch. In April 2020 NASA teamed up with Xometry to fast-track a critical life support system on the international space station. Xometry was able to produce an air purification unit for NASA’s ECLSS team, which is on track to launch in 2021.

ExOne joins the RFQ Marketplace

Xometry’s digital RFQ marketplace enables customers to request quotes on a wide range of 3D metal printing services and pairs them with job-specific suppliers. The platform also offers over-the-counter (OTC), peer-to-peer trade negotiation and an execution platform that links dealers to customers. Clients using the virtual service are able to negotiate complex and customized high-value trades in privacy.

By teaming up with ExOne, Xometry has now further expanded its 3D printing services to include a new range of industrial sand and metal binder jetting 3D printers. ExOne currently prints more than 20 materials including 316L and 17-4PH stainless steels, Inconel 718 and M2 Tool Steel, and Xometry will now add these to its available materials portfolio.

Through the deal, Xometry customers will benefit from ExOne’s binder jet printing technology, which provides a cost-effective alternative to Metal Injection Molding (MIM). Binder jetting enables the production of multiple parts in one build, and the rapid printing of mid-to high-volume runs, enabling Xometry’s clients to scale their manufacturing capabilities.

John Hartner, CEO at ExOne said the deal with Xometry could provide both industrial and ecological benefits in the long-term. “ExOne is proud to offer our metal 3D printing services to Xometry customers,” said John Hartner, “Our industrial binder jet machines can truly take products from prototyping all the way to final production with a single process that is fast, affordable and sustainable.”

ExOne’s collaborations and Initiatives

ExOne has teamed up with a number of partners over the years in order to develop the applications of its binder jetting services.

In April 2020, ExOne teamed up with University of Pittsburgh to develop reusable metal filters that fit into plastic respirator cartridges. The company’s binder jetting technology allowed it to produce metal parts with specific porosity levels that can effectively filter out contaminants while allowing airflow.

In July 2020, ExOne launched its Sand 3D printing Network which provided more than 40 of its systems to clients in a range of manufacturing sectors. Members of the network reportedly benefit from the advice of trained operators, and order turnaround times of three to five days.

ExOne also announced a number of collaborations to simplify sintering for metal binder jet 3D printing in 2019. Partnering with engineering simulation company ANSYS, the firm developed software for predicting the sintering behavior of metal 3D printed parts.

What companies do you think are leading the 3D printing industry? Let us know by nominating them for the 2020 3D printing Industry Awards.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway! Enter your design for your chance to win a CraftBot Flow 3D printer.

Check us out on Twitter and Facebook for more updates! Don’t forget to subscribe to the 3D Printing Industry newsletter and keep up-to-date with the latest 3D printing news.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the additive manufacturing industry.

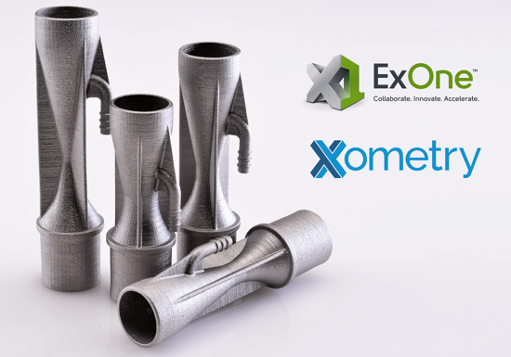

Featured image shows a set of 3D printed Venturi Valves, produced using ExOne’s 3D printing technology and 316L stainless steel. Photo via ExOne.