A patient at Morriston Hospital in Wales has been the first in the world to receive a jaw reconstruction surgery combining traditional bone grafts and 3D printed Titanium implants.

Debbie Hawkins, from Swansea, received the treatment funded by the UK’s National Health Service (NHS), following cancer treatment that excised a part of her jaw bone.

The combined implant surgery was used in order to accurately maintain both the natural shape of the jawline and to allow dental implants to be inserted.

The problem of jaw reconstruction

The traditional procedure for reconstructing the jawline involves taking bone from the patient’s fibula (thigh bone). To then maintain the aesthetic shape of the jaw, the bone graft must be set lower than the jawbone would normally sit, too low for dental implants. To allow dental implants to be set into the jawline, the bone graft must be placed higher than the natural position of the jaw, making it lose its natural shape.

One solution to this is to trim the fibula bone graft according to the patient’s jaw line and then hold it in place with a metal plate. The surgeon must bend this plate by eye, which makes accuracy difficult.

Surgery guided by 3D technology

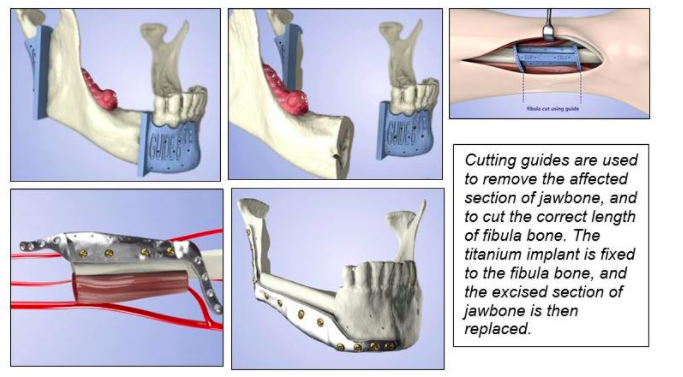

The team at Morriston used 3D technology throughout the entire surgical procedure. CT images were taken, and a customised, anatomically accurate titanium implant was 3D printed. This implant both fixed the fibula bone where implants could be set and maintained the aesthetic shape of the jaw line.

Laboratory Services Manager Peter Llewelyn Evans, who designed the implant with 3D technician Heather Goodrum, said, “we used the CT image of the patient’s jaw on the other side and mirrored it, and the design of the implant and cutting guides is based on that shape.”

The technicians also created accurate cutting guides for the surgical team, ensuring that the fibula length taken from the leg matched the length required for the jaw reconstruction. Evans added that “the titanium implant fits the patient’s jaw perfectly without the surgeon having to do any adjustment…similarly, using cutting guides means the section of fibula exactly matches the section of jawbone removed.”

A safer surgical procedure

The maxillofacial surgeons completing the procedure, Madhav Kittur, Ketan Shah and Simon Hodder, were left to focus on the task of connecting the fibula to blood vessels in the neck to ensure the bone didn’t die.

Kittur, who led the surgical team, stated that with the prior experience of four procedures using 3D preparations meant “it has taken away the uncertainty. We know exactly what is going to happen before we go into theatre as everything is computer planned.”

He also noted that the time of the surgery, which usually takes eight to ten hours, was cut by two hours. “This is a big advance,” he added, “it’s better aesthetically, the patient is under anaesthetic for less time, and recovery is better.” Hawkins is yet to receive dental implants, but appears to have recovered well from the procedure.

Morriston’s leading surgical team

Surgeons at Morriston have previously reconstructed a motorbike accident victim’s face using 3D printed implants. Heather Goodrum, the NHS’ first ever biomedical technician specialising in 3D printed facial reconstruction was appointed earlier this year and is based at Morriston.

For more on innovative medical procedures involving 3D printing and scanning, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows Deborah Hawkins with the team at Morriston. Photo via NHS Wales.