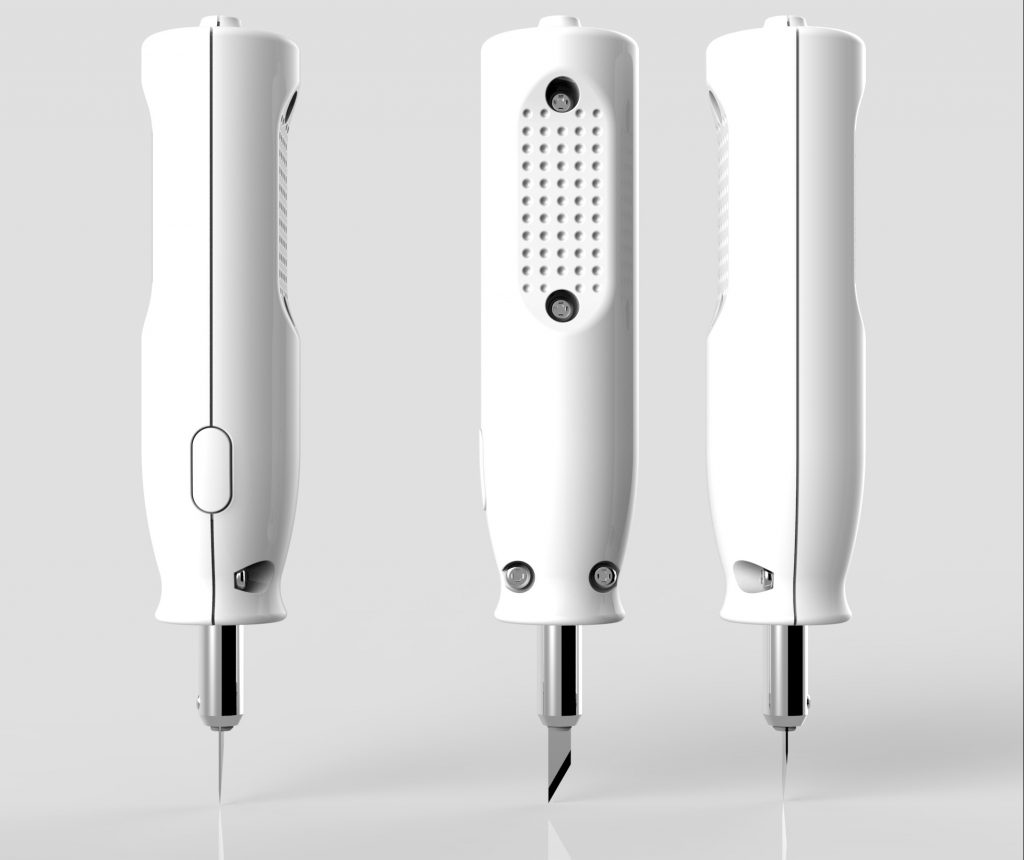

WonderCutter is a handheld ultrasonic cutter that combines razor blades with a 40-kilohertz ultrasonic vibration to make cutting plastic as easy as cutting cheese.

Launched by Korean manufacturer Cutra, the WonderCutter claimed the Gold prize at the International Exhibition of Inventions of Geneva 2016. It drew in $50,000 in just five days on its Kickstarter, which is still running.

Good vibrations

Whether removing supports from 3D printed objects or reshaping PCB boards, cutting through plastic is often challenging, time-consuming and inaccurate. It is a problem that Cutra CEO Juhyeon Kim decided to solve by harnessing the power of ultrasonic vibration.

“The ultrasonic cutter…is perfect for cutting, but its only problem is the price that goes up to million dollars…” explained Kim. His thought process behind the solution to this was “what if we miniaturize these cutters and make something affordable and easy to use…?”

The WonderCutter can cut through resistant materials by lowering the coefficient of friction between the cutting blade and the material being cut. It achieves this by rapidly oscillating the blade with 40,000 invisible vibrations per second.

With a reduced coefficient of friction, detailed and precise cuts can be performed accurately without the material heating up or shattering from stress. This would be difficult to accomplish with either traditional tools such as scissors or guillotines and even with more advanced tools like electric saws or lasers.

The possibilities of ultrasonic technology

Besides plastics (including PLA and ABS) and PCB, the WonderCutter can be used to cut and shape fabric, felt, plywood, acrylic, rubber and even leather, making it accessible to a wide range of practitioners. The WonderCutter cannot incise metal or glass.

“We cut paper with scissors. We make a hole in the wall with a drill. We cut wood with a saw. Then how do we cut plastic that is used so often?” said Kim. “There is nothing like building and making things with your own hands to improve your self-esteem and confidence.

“My colleagues and I wanted to invent a safe and handy tool that allows everyone to use it very easily.”

A WonderCutter kit consists of the main body (measuring 17.4×10.1×6.2cm and weighing 680 grams), a charger pack, a set of blades, and a pair of safety gloves. Built-in features include screwable blade replacement, a belt clip for portable use, and power surge protection. As an additional safety feature, the ultrasonic capability is only active while the operation button is pressed down.

Click here to back the WonderCutter on Kickstarter before it ends.

This article was sponsored by WonderCutter.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections now.

For more stories on tools for 3D printing and post-processing, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the WonderCutter in action. Gif via WonderCutter.