The additive manufacturing arm of multinational company Wipro have announced a new partnership with Print Form.

3D printing consultancy firm Print Form are headquartered in Atlanta, USA with a localized Innovation Center in Mumbai. Additive manufacturing faction Wipro3D are based in Bengaluru and provide additive services for aerospace, medical and industrial tooling industries.

A more systemic and sustainable service

According to Ajay Parikh Business Head at Wipro3D, the partnership is intended to boost their international customer-base and provide additional consultation support to the service. Parikh says they will be “working together with Print Form to help enterprises adopt metal additive manufacturing in a systematic and sustainable way.”

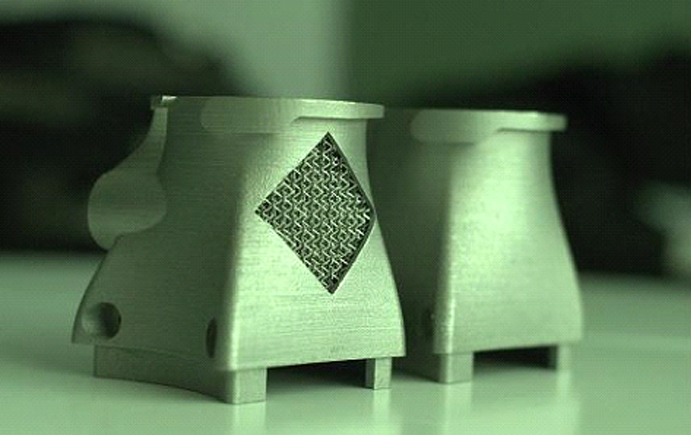

The partnership also strengthens Print Form’s existing DMLS and SLS capacity for prototyping and end user parts. CEO and co-founder of Print Form, Brian Ford adds:

WIPRO3D is the first group that I have encountered that can provide complete concept to realization services, including engineering design, materials expertise, design for additive manufacturing analysis, and custom parameter development.

In 2016, Wipro3D partnered with 3D printing bureau Authentise to expand their 3D printing capabilities.

National development of advanced manufacturing in India

The partnership comes just months after the Indian Government announced their development of a National Policy for Advanced Manufacturing to increase its manufacturing output by 9% of the country’s GDP. The government initiative hopes to accelerate the use of advanced manufacturing to enable the country to compete globally.

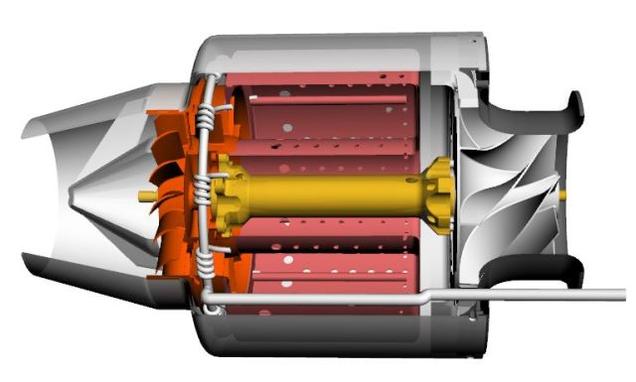

Another project contributing to this projection is Bengaluru based Intech DMLS. Intech are in the process of producing a 3D printed jet engine to serve small UAV aircraft. After quick turnaround of the certification process, the plan is to scale-up production and produce more industrial sized combustion engines.

Don’t forget to make your nominations for the 1st Annual 3D Printing Industry Awards. Nominations are closing soon.

Featured image shows 3D printed metal gears printed by XJet Nano Particle Jetting. Photo by Michael Petch