The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now.

Italian 3D printer manufacturer WASP has provided an update on its ongoing partnership with the European R&D arm of Japanese automotive manufacturer Honda.

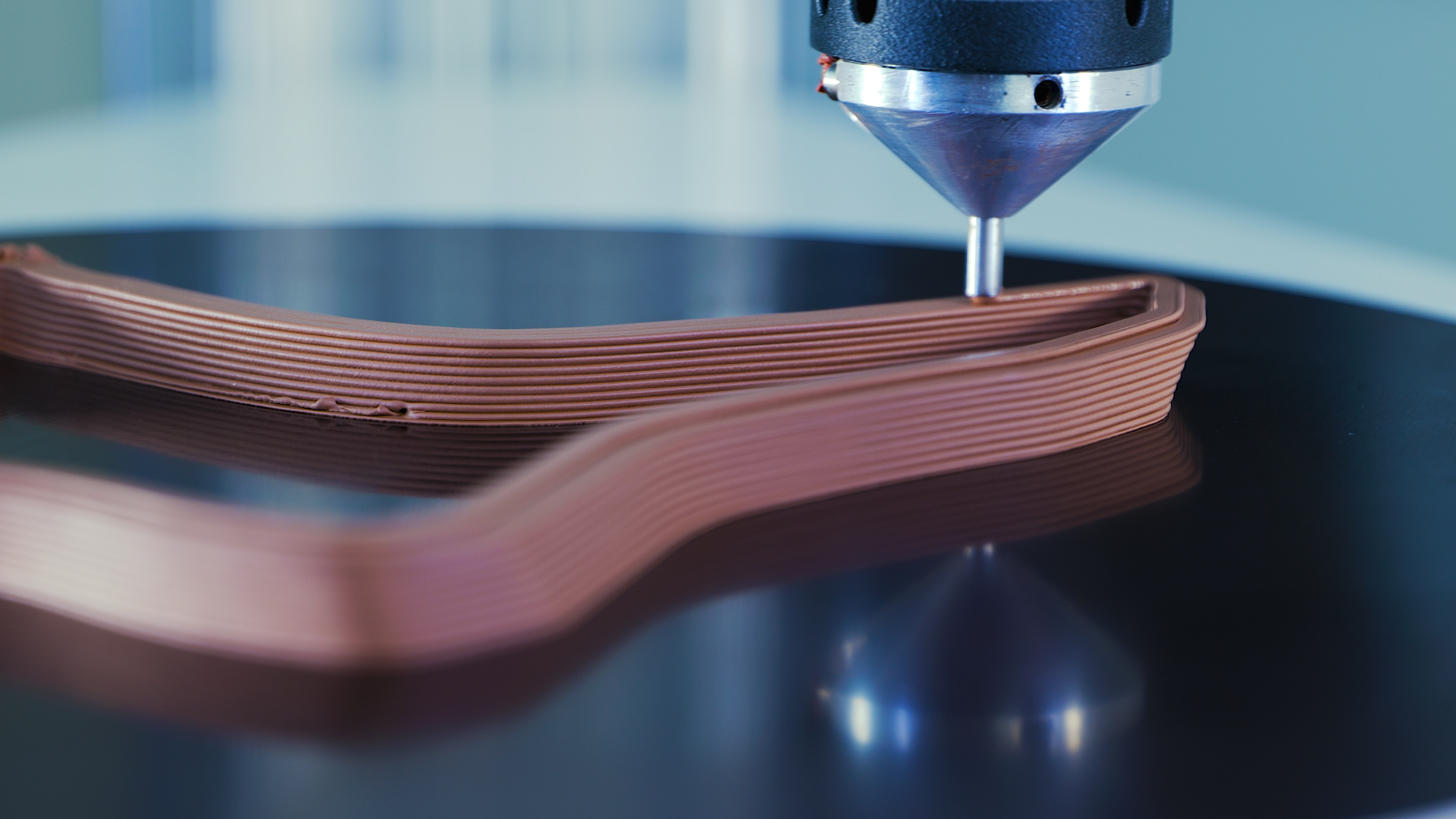

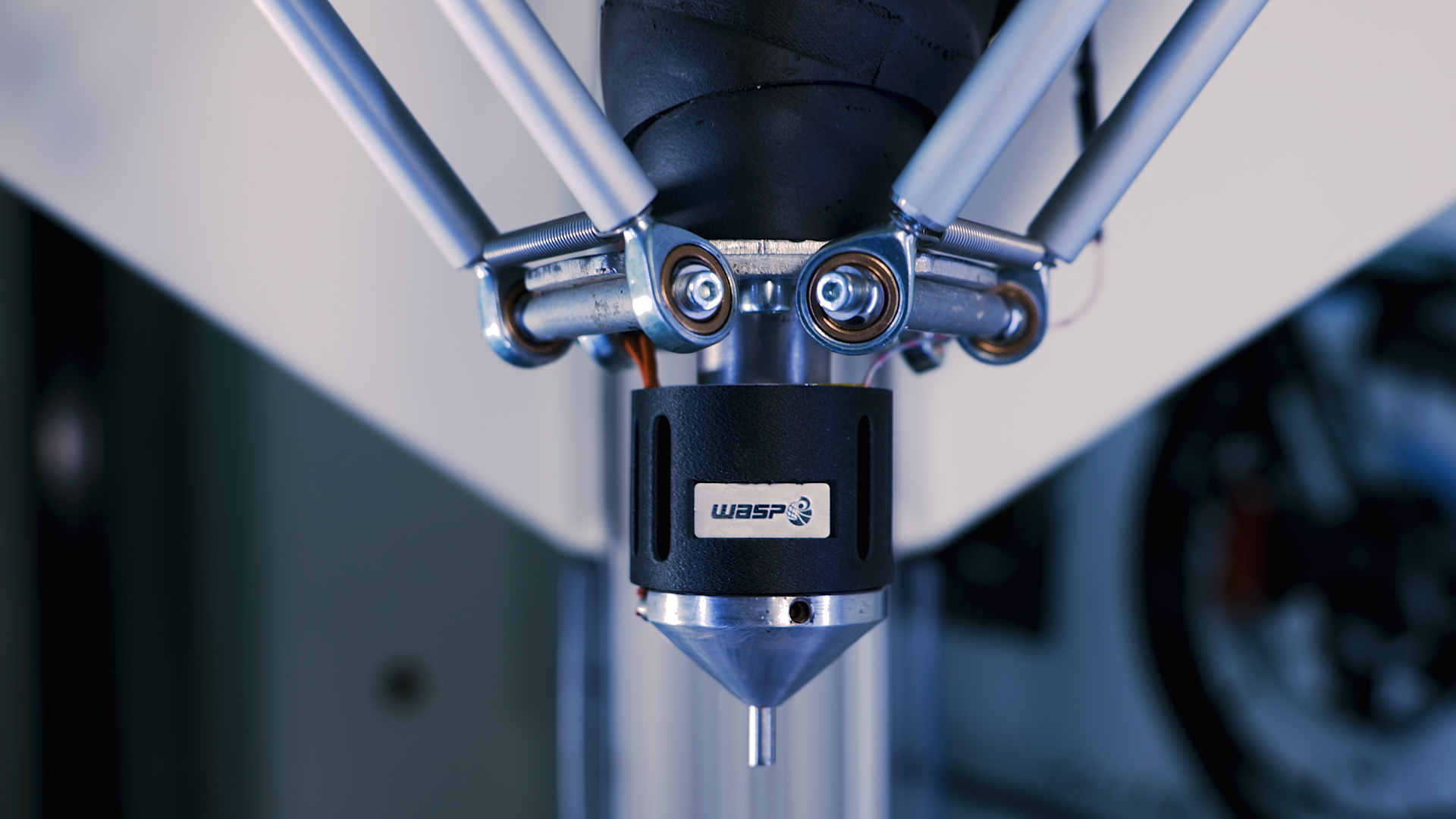

Since announcing their joint project in April, the companies have been developing WASP’s Liquid Deposition Modeling (LDM) 3D printing technology to provide greater freedom within clay motorcycle modeling. The process is leveraged by WASP’s DELTA WASP 40100 Clay 3D printer, which is able to extrude clay in a “never-ending” cycle.

“The technological innovation consists in keeping at a constant temperature the whole system made by tank, connection pipe and extruder,” said Nicola Schiavarelli, Product Manager and Co-founder of WASP. “WASP research has led to the creation of a revolutionary machine for printing industrial clay, the DELTA WASP 40100 clay, able to extrude and make the material never-ending and reusable.

“Therefore, we consider WASP’s collaborative 3D printing a new concept in the additive industry.”

WASP’s clay 3D printing

Founded in 2012, WASP’s mission is to develop viable construction processes based on the principles of the circular economy and reusability. Among other materials, its systems use clay-based feedstock to build sustainable structures such as buildings and creative works.

Over the last few years, WASP has deployed its CRANE WASP 3D printer to build a 9.8 foot tall bio-building named Gaia out of naturally-sourced materials, and its organic proof-of-concept TECLA eco-habitat. Both projects leverage local, natural, and waste materials in order to showcase how construction can have a minimal impact on the surrounding area and promote a model for more sustainable house building.

Aside from buildings, WASP has previously used its Delta WASP 40100 Clay 3D printer to 3D print ikebana vases for esteemed Italian artist and sculptor Andrea Salvatori. The system is specially engineered to enable users to explore the 3D printing of ceramics on the desktop and at scale.

WASP has been working on its industrial clay extrusion process since 2017, and has continued this work in partnership with Honda.

Industrial clay modeling for motorbikes

Industrial clay is commonly used to prototype new part designs within motorbike manufacturing, however the manual modeling process can be slow. To address this, WASP and Honda came together in April in a bid to combine clay modeling with mass manufacturing.

Honda has integrated WASP’s 3D printing technology into its creative process in order to shorten its vehicles’ time to market, creating a hybrid approach to industrial clay modeling that modernizes its workflow while retaining the artistry associated with hand-crafted motorcycles.

Since first announcing the partnership, the companies have worked on developing WASP’s LDM clay 3D printing technology to optimize the speed of creating the models. WASP’s LDM technology works by extruding ceramic materials and reusable natural materials found in the local soil to form a clay-based 3D printed model.

Reportedly “zero-emission” and adaptable to any climate, the process is also being improved to be able to deposit heated dense fluid materials.

According to Antonio Arcadu, Design Modeling Coordinator at Honda R&D Europe, the role of the modeler is central to the project. They will be responsible for the entire production process of the clay prototypes, beginning with the 3D design all the way through to the final hand-made manufacturing phase, which can also be replaced by clay milling or other subtractive processes.

“In order to preserve the creative process, we cannot rely on technology alone, but we need modelers not to interrupt their connection with matter in its most direct form: the hands,” he said. “Although this is a newly introduced process it can be considered disruptive in the automotive sector because it introduces a new flow, mostly additive, able to optimize processing times and reduce the amount of material used in the traditional and subtractive processes.”

According to Schiavarelli, the project is “not stopping here”, outlining the technology’s potential within other applications such as sculptures, models, prototypes and other design-led projects, due to its ability to reduce costs and manufacturing time without impacting labor forces.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows WASP and Honda have continued their partnership to speed up industrial clay motorcycle modeling. Image via WASP.