voxeljet, a manufacturer of large-format 3D printers and casting molds has announced a 3-year Volume Contract with Tooling and Equipment International (TEI), a producer of cast metal parts.

As part of the deal, TEI will purchase over 500,000 liters of 3D printed sand from voxeljet, which will also install its large-format 3D printers at TEI’s facility in Livonia, Michigan.

3D printed sand for casting

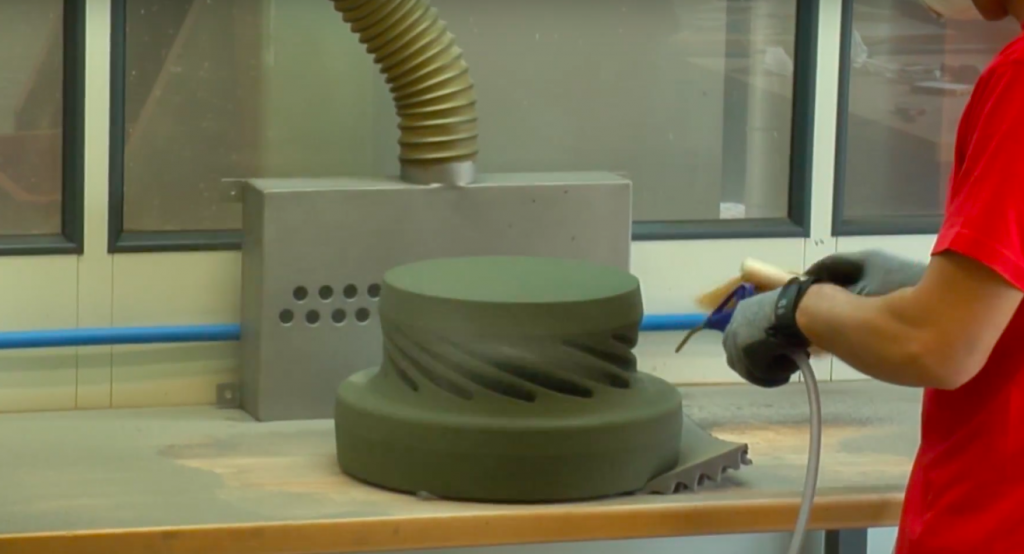

Sand casting is a process where molten metal is poured into molds made of sand and cast into shapes. These molds can be produced using a binder jetting 3D printing process, where sand is applied in layers and selectively bound with an agent into the desired shape.

3D printing is an economical way of producing casting molds without the need for complex and expensive tools. voxeljet 3D prints sand molds using its large-format 3D printers, which have a build volume of up to 4,000 x 2,000 x 1,000 mm, and bind the sand using cold-hardening furan resin.

Binder jetting produces molds with sophisticated geometries, undercuts, and a smooth surface quality. The sand can also be removed and recycled after casting.

Casting call for TEI

TEI is the largest user of 3D printed sand in the USA, producing prototypes and low volume components in aluminum, iron, and steel. These cast parts are predominantly used by the automotive, aerospace and defense industries.

With the addition of voxeljet’s large-format 3D printers, TEI will now bring its full industrial process into a single facility. This includes design, 3D sand printing, casting, heat treatment, machining, and post-machining inspection.

Oliver Johnson, President of TEI commented:

“With voxeljet working alongside us to supply molds and cores, we will be able to compress lead times even further for our customers while also setting new records in terms of the size and weight of parts we can cast.”

“The 3D printing industry is at an inflection point, and this marks another milestone in our mission to push 3D printing into industrial production,” added David Tait, voxeljet’s Managing Director.

Let us know what you think the most innovative 3D printing OEM has been this year. Nominations for the 3D Printing Industry Awards 2018 are only open for another week. Submit yours now.

Think you have the winning design for this year’s trophy? Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your design now to win a 3D printer.

For more stories on 3D printing and metal casting, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows a cast metal part from a 3D printed sand mold. Photo via voxeljet.