German 3D printer manufacturer voxeljet has reported a return to annual growth in its Q3 2020 financials, achieving a revenue increase of 10 percent during the period.

For the three months ending September 30th 2020, voxeljet generated €4.9 million in consolidated revenue, a 10 percent rise compared to the €4.4 million reported in Q3 2019. This figure, which represents a 32.5 percent increase on the firm’s revenue decline in Q2 2020, was primarily driven by a 64 percent improvement in its Systems revenue.

Since Desktop Metal announced its IPO earlier this year, binder jetting technologies have seen a surge in public interest, and this could have been a factor in voxeljet’s Systems success during Q3. ExOne for instance, which also manufactures binder jet machines, doubled its 3D printer sales between Q3 2019 and Q3 2020.

Despite this, voxeljet anticipates a more difficult than initially expected Q4 2020, and lowered its revenue guidance for the quarter accordingly, to between €8 million and €10 million. As a result, even though the company achieved revenue growth during Q3, its shares dipped from $8.90 to $8.46 after the publication of the results.

Voxeljet’s Q3 2020 financial results

Voxeljet uses its High-Speed Sintering (HSS) and binder jet 3D printers to provide an on-demand manufacturing service within Germany, the US, UK, China, and India. The revenue that the company gains from its production solutions are reported under two segments: Systems and Services.

Within the company’s Systems segment, it includes revenue gained from machine sales as well as selling spare parts, upgrades, maintenance contracts and other sales-related activities. During Q3 2020, voxeljet generated €2.6 million in Systems revenue constituting a 64 percent increase on the €1.6 million reported in Q3 2019.

Over the course of Q3 2020, voxeljet sold two unspecified used and refurbished 3D printers, compared to the three new systems it installed in Q3 2019. The company has attributed the segment’s significant revenue increase to its “increased product mix,” meaning that it sold more of its larger format and ultimately more expensive machines, than it did in Q3 2019.

Voxeljet’s Services segment, which focuses on its on-demand 3D printing revenue didn’t perform as well, generating €2.2 million in Q3 2020 compared to the €2.8 million reported in Q3 2019. This 20 percent decline was accounted for by the performance of the firm’s UK and US-based spare parts businesses, which earned less revenue than they did in Q3 2019.

| Revenue (€) | ||||||

| Segment | Q3 2019 | Q3 2020 | Variance (%) | 9M 2019 | 9M 2020 | Variance (%) |

| Systems | 1.6m | 2.6m | +64 | 6.1m | 5.8m | -5 |

| Services | 2.8m | 2.2m | -20 | 8.8m | 6.8m | -23 |

| Total | 4.4m | 4.9m | +10 | 15m | 12.7m | -15 |

voxeljet’s return to growth during Q3 2020

The firm has largely attributed its increased Systems revenue to the larger scale printers it sold during Q3 2020, which yielded a higher return than the small machine contracts it gained in Q3 2019. Voxeljet also managed to improve its consumables revenue over the same period due to its higher install base, although not by enough to generate annual growth.

According to the company, its System revenue could have increased by even more, but for the continued impact of COVID-19 on its ability to complete installations. The pandemic’s travel restrictions prevented voxeljet from fulfilling many of its scheduled installations during Q3 2020, meaning that it wasn’t able to add this revenue to its financial figures.

Similarly, the metal 3D printing firm was unable to perform regular servicing visits, and its on-demand manufacturing business continued to struggle, as its clients remain cautious on their spending. Despite COVID-19’s ongoing impact, voxeljet’s Systems division still made up 54.7 percent of its total revenue during Q3 2020, an 18 percent increase on 36.9 percent seen in Q3 2019.

The company also attributed its Services decline to the effects of the pandemic, which caused a significant decline in demand for its US-based on-demand parts business. Additionally, voxeljet closed its service center in the UK as part of a broader restructuring in Q4 2019, and this has had a knock-on effect on the profitability of its subsidiary there.

In order to mitigate some of the revenue losses incurred due to the pandemic, the firm cut its R&D spending from €1.8 million in Q3 2019 to €1.4 million in Q3 2020. As part of the “Essentials2020+” program that voxeljet announced in Q3, it intends to concentrate its future spending on the sales and development of its VJET X and VX1000 HSS systems.

Looking ahead to Q4 2020 and the VX1000

As the company moves into the fourth quarter, it has lowered its full-year revenue forecast from €26 million-€30 million to €20.7 million-€22.7 million. As COVID-related travel restrictions continue to be reimposed, voxeljet has admitted that this could cause further delays to its 3D printer installations, and lowered its forecast accordingly.

Despite this, the firm has an order backlog of €9.4 million, leaving it in a much healthier position than the €2.7 million worth of orders it had at the start of the year. Given that its average installation lead time is 9 months, there’s no guarantee that voxeljet will quickly convert these sales into revenue, but it shows that it’s still benefiting from increased interest in its machines.

In future, the company believes that the scalability of its VX1000 system will lead to “multiple installations,” and it’s currently validating materials for the machine with Covestro ahead of a 2021 launch. According to Dr. Ingo Ederer, CEO of voxeljet, the firm’s upcoming VX1000 and XJET X will open new opportunities for the firm’s technologies going forward.

“We have reached significant milestones with the VJET X and new, large High Speed Sintering (“HSS”) 3D printer over the last months,” said Ederer. “First printing tests on the large HSS printer were successful, and we are extremely excited about the new opportunities and markets we plan to address with it.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

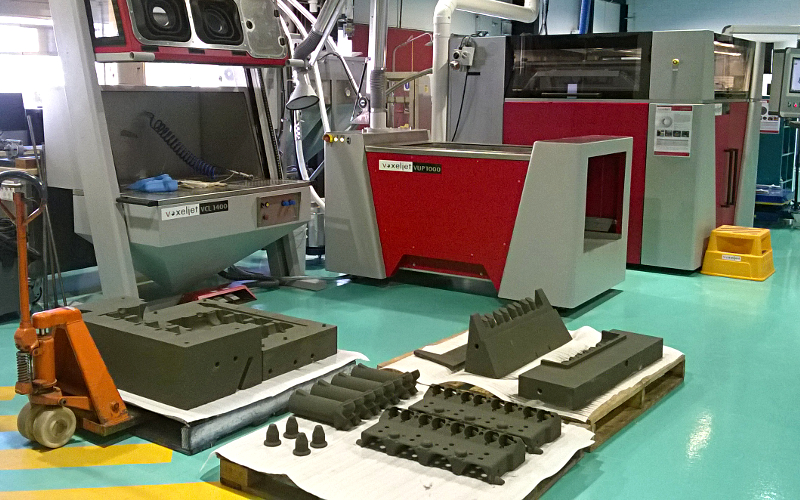

Featured image shows a voxeljet system being used to 3D print sand molds at CSIRO Lab 22. Photo via voxeljet.