VELO3D, the Californian metal 3D printer manufacturer behind the Sapphire DMLS systems, has announced it has raised $28 million in a Series D funding round.

New investors Piva, a Californian venture capital firm, led the round with the largest investment; the company is backed by PETRONAS, a government-owned oil and gas company based in Malaysia. Taiyo Nippon Sanso Corp, a Japanese multinational industrial gas manufacturer also joined the round alongside existing investors Bessemer Venture Partners, Playground, and Khosla Ventures.

With this latest investment round, VELO3D’s total funding is $138 million. The company plans to use the new capital to expand its product portfolio, in order to deliver more machine options and compatible alloys.

“VELO3D is revolutionizing the way we think about advanced manufacturing today,” comments Ricardo Angel, CEO and Managing Partner at Piva. “We have been impressed by Benny, the team and their breakthrough technology that will have a significant impact on the efficient design and manufacturing of more complex components, previously unattainable, with clear commercial traction already in the aerospace and aviation markets.”

“VELO3D will lead a new wave of more resilient, distributed manufacturing capabilities for its most critical components, which the world will need to ensure local product availability and timeliness, while mitigating potential future worldwide disruptions.”

VELO3D metal 3D printing technology

Founded in 2014, VELO3D is a developer of Direct Metal Laser Sintering (DMLS) additive manufacturing systems and print preparation software. VELO3D operated in stealth mode for its first 4 years, having raised $22.1 million in a Series A funding round in 2015. 3D Printing Industry was in Chicago when the company revealed its first Sapphire DMLS system in 2018 at the International Manufacturing Technology Show (IMTS).

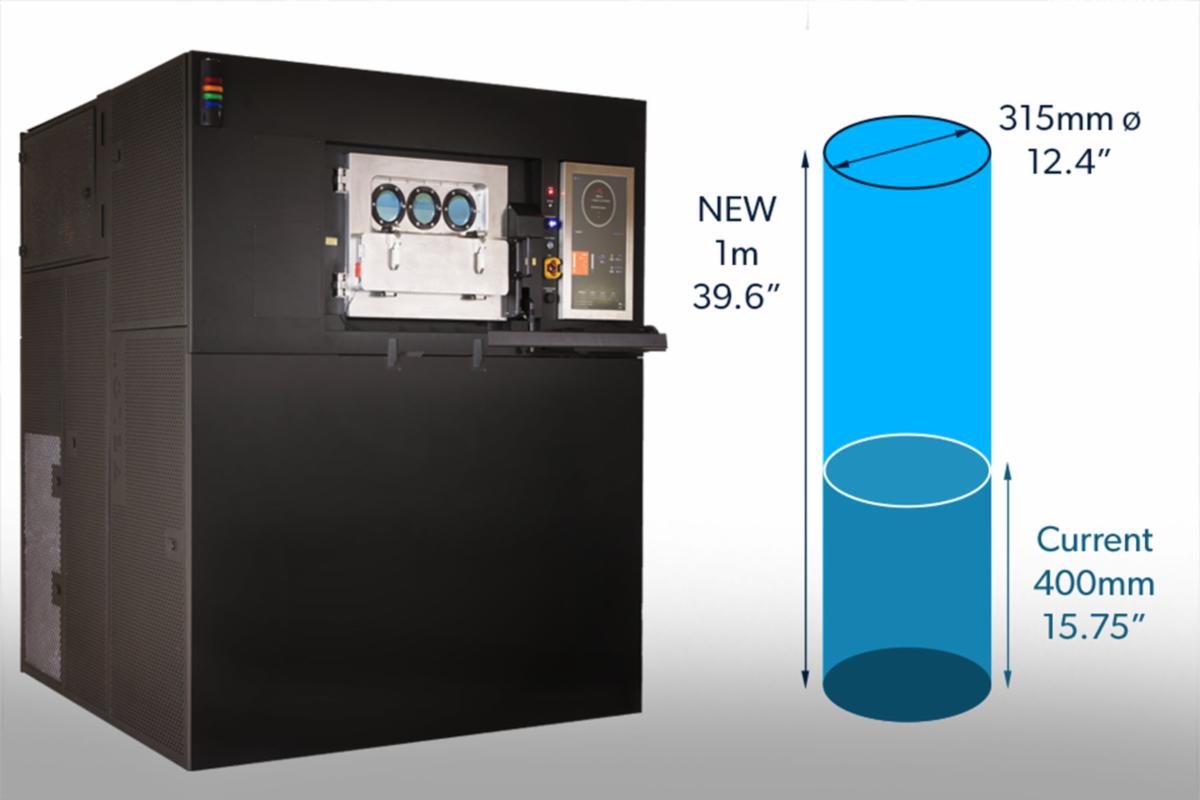

Featuring a 315 mm diameter by 400 mm height build envelope, the Sapphire system makes use of VELO3D’s intelligent fusion technology. This technology simulates and predicts part deformation, counterbalances this deformation by adjusting the part design, and works with the feed-forward closed-loop melt pool control and in-situ metrology data to produce a part with minimal to no support structures.

VELO3D announced commercial availability of the Sapphire system in 2019, after which the company generated nearly $30 million in sales and gained seven new customers in that same year, many of which have placed repeat orders. The system has attracted customers from the aerospace sector since its commercial launch, including an order of seven Sapphire 3D printers from an unknown aerospace manufacturer.

Earlier this month, VELO3D announced the launch of the next-generation Sapphire metal additive manufacturing system, developed with a focus on build-chamber size. As such, it extends the build of the previous system to 315mm diameter by 1 meter height volume.

Expanding machine and software portfolio

VELO3D plans to leverage its new $28 million investment to help further expand its 3D printer portfolio offering. Additionally, the company intends to increase the number of compatible alloys with its systems in order to enable the 3D printing of mission-critical metal parts for demanding applications.

The funding will also be used by the company to enhance its software and hardware capabilities. VELO3D develops and provides two pieces of software technology: its Flow product is a print preparation software kit designed to ensure predictable 3D print outcomes; and its Assure software is a quality assurance system providing machine traceability, part integrity and build reporting.

With the new funding, the company expects to reach sustainable profitability by mid-2022. “With the VELO3D integrated solution of Flow advanced pre-print software, Sapphire printer, and Assure quality management software, companies can finally break free of the constraints of existing metal additive manufacturing processes,” states Benny Buller, Founder and CEO of VELO3D.

“Customers in industries such as aerospace, oil & gas, and power generation are now able to achieve part quality for their mission-critical applications with performance levels that weren’t possible before with 3D metal printing.”

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the VELO3D Sapphire System. Photo via VELO3D.