Researchers from the US Army Research Laboratory (ARL) have partnered with several US-based universities to develop a miniaturized 3D printed holographic instrument.

The team’s Holographic Aerosol Particle Imager (or HAPI), is capable of imaging and characterizing multiple particles from any given direction in a single measurement, without making physical contact with them. During testing, HAPI was deployed via drone to capture and identify naturally-occurring aerosols, and using a Digital Holography (DH) technique, it managed to log particles sized ten micrometers or more.

With further tinkering, the team believes that their novel device could be used to identify potential aerosol threats in the field and contribute to the situational awareness and lethality of US soldiers.

“This research is unique because it uses holography to characterize aerosol particles by capturing images of their physical shape,” said ARL researcher Dr. Gorden Videen. “This has not been done before, and the latest step is to miniaturize the instrument, put it onto a drone, and fly it around to capture these images in-situ.”

“This is a major step forward, and it was implemented in a relatively short amount of time.”

The importance of understanding the atmosphere

Understanding both the composition and behaviors of everyday airborne particles isn’t just important for military reasons, but getting a grip on global warming too. The ‘radiative forcing’ that takes place in natural aerosols can reflect greenhouse gas levels, as well as being an indicator of the air’s toxicity to human life.

Despite this, the broader impact of aerosols on the Earth’s climate is not well understood, and this is largely due to limited data on the morphology of ‘Coarse Mode Aerosols’ (CMAs) or particles sized 1𝜇m or less. At present, particles are often studied in conjunction with ground and satellite data, but more accurate methods are needed in the future, in order to record their exact microphysical characteristics.

Optical light scattering generally offers a more suitable detection technique, as it’s both rapid and contact-free, but a particle’s scattering pattern depends heavily on its morphology. In prior research, it has proved impossible to identify an exact relationship between a measured pattern and precise particle features, and as a result, previous studies have not yet yielded an effective holographic device.

The US Army team’s HAPI device

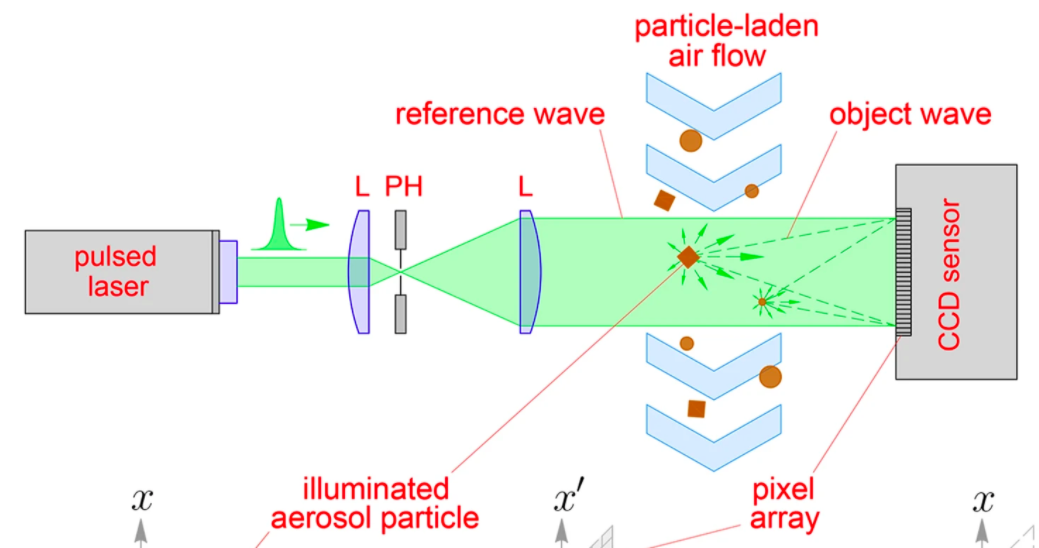

The Army-led researchers tackled these limitations by fitting their contraption with an in-line DH aerosol characterization system. In principle, the device uses a laser beam (placed a few centimeters from a sensor) to measure passing particles and this forms a “reference wave.” The small amounts of light scattered by the particles as they cross the beam, subsequently cause a more accurate “object wave.”

Within the advanced process, if the laser is “pulsed,” the particles passing through the object wave can be “frozen” as it effectively takes a snapshot of their precise features at that moment. In order to deploy the DH process in a more cost-effective manner than commercial aircraft or a research balloon, the team decided to create HAPI, and attach it to a UAV.

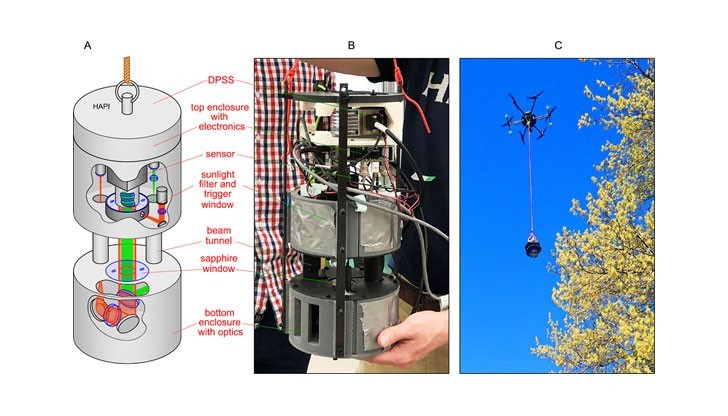

The researchers’ novel holographic device consisted of three stacked cylindrical containers, housing electronics, sensing, and optical technologies. HAPI’s structural elements needed to be light enough to be carried by an inexpensive UAV, hence they were fabricated using a Formlabs Form 2 3D printer and low-cost polymers.

Once built, the team tested HAPI in several locations near Kansas State University (KSU) to investigate the aerosol particles emitted from two sources: live pollen emitted from a tree, and mineral dust caused by passing traffic. Summary testing revealed that CMA particles larger than 10𝜇m could be imaged at a sensing volume of ∼3cm3 with enough detail to precisely measure their size and shape.

With sufficient computing resources, the researchers believe that captured data could be analyzed on-site, providing real-time feedback on the anticipated direction of travel of any given aerosol. According to Dr. Videen, HAPI could be deployed in the field by US soldiers, potentially enabling them to identify and avoid any harmful airborne chemicals or toxins.

“One of our goals is to identify threat aerosols, like biological warfare agents,” added Dr. Videen. “In order to do this, we need to develop new techniques that can rapidly detect and characterize aerosols. This technology provides a new type of aerosol information that can be incorporated into detectors.”

The ARL’s recent additive innovations

Recently, the US ARL has been heavily involved in developing enhanced 3D printing materials, processes, and devices, that are custom-made to improve the combat chances of its soldiers.

Working with researchers from Texas A&M University, the ARL produced a new family of recyclable, self-healing polymeric 3D printing materials. According to the research team, the technology could be utilized within applications ranging from artificial limbs to flexible aerospace components.

The ARL has also discovered a method of predicting the performance of 3D printed parts and understanding any subsequent imperfections that affect their performance. In a recent military study, soldiers were able to use sensor measurements to predict when parts would degrade or need replacement, allowing them to maintain combat readiness.

Elsewhere, the US Army Aeromedical Research Laboratory has 3D printed and successfully tested customizable earplugs for members of the US Armed Forces. The innovative ear protectors have the potential to prevent any hearing damage caused to soldiers by gunfire on the battlefield.

The researchers’ findings are detailed in their paper titled “Imaging atmospheric aerosol particles from a UAV with digital holography,” which was authored by Osku Kemppinen, Jesse C. Laning, Ryan D. Mersmann, Gorden Videen, and Matthew J. Berg.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ARL-led team’s 3D printed holography device. Photo via the Scientific Reports journal.