A new 3D bioprinting method has been developed by biomedical engineers from the University of Utah.

With the aim to improve a patient’s recovery, biomedical engineering assistant professor Robby Bowles, and his team, have developed a method to 3D print stem cells from a patient’s own body fat to form tendons and ligaments.

“[This] will allow patients to receive replacement tissues without additional surgeries and without having to harvest tissue from other sites, which has its own source of problems,” said Professor Bowles.

Controlling cell deposition

Following two years of research, Professor Bowles and his team created a 12-channel pilot printhead to enable the deposition of stem cells in complex patterns said to be previously unattainable. The researchers state that “cells that make up a tendon or ligament must gradually shift to bone cells so the tissue can attach to the bone.” Professor Bowles added:

“This is a technique in a very controlled manner to create a pattern and organizations of cells that you couldn’t create with previous technologies. It allows us to very specifically put cells where we want them.”

The bioengineers collaborated with Carterra, Inc., Salt Lake City-based developers of microfluidic medical devices, to create the printhead. This custom part was then attached to a Carterra 3D printer which was formerly used to deposit antibodies for cancer screening applications.

According to the research team, replacement tissue harvested from another part of the patient’s body or a cadaver can be of poor quality. Such areas as spinal discs contain “complicated structures with bony interfaces that must be recreated to be successfully transplanted.” This motivated the team to create a new 3D printing technique to remedy such problems.

Furthermore, Bowles believes the technology in the printhead could be adapted for any kind of 3D printer and contributes to the goal of 3D printing whole organs.

Regenerative medicine and 3D printing

Additive manufacturing has proven to be an asset in biological studies and experimentation. In the realm of regenerative medicine, 3D bioprinting has allowed for the creation of cell structures that work to heal wounds inside the human body.

Earlier this year, researchers from George Washington University (GWU) developed a 3D bioprinting technique to create multi-responsive smart structures for nerve regeneration. Prior to this, a study produced by four research institutions in Brazil demonstrated the ability of two 3D printable biocompatible polymers to create structures ideal for cell-growth.

The method article “Microfluidic Flow Cell Array for Controlled Cell Deposition in Engineered Musculoskeletal Tissue” is co-authored by David Ede, Nikki Davidoff, Alejandro Blitch, Niloofar Farhang, and Robby D. Bowles.

For more on the latest additive manufacturing news, subscribe to the 3D Printing Industry newsletter, like us Facebook and follow us on Twitter.

Looking for a change of pace or searching for talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

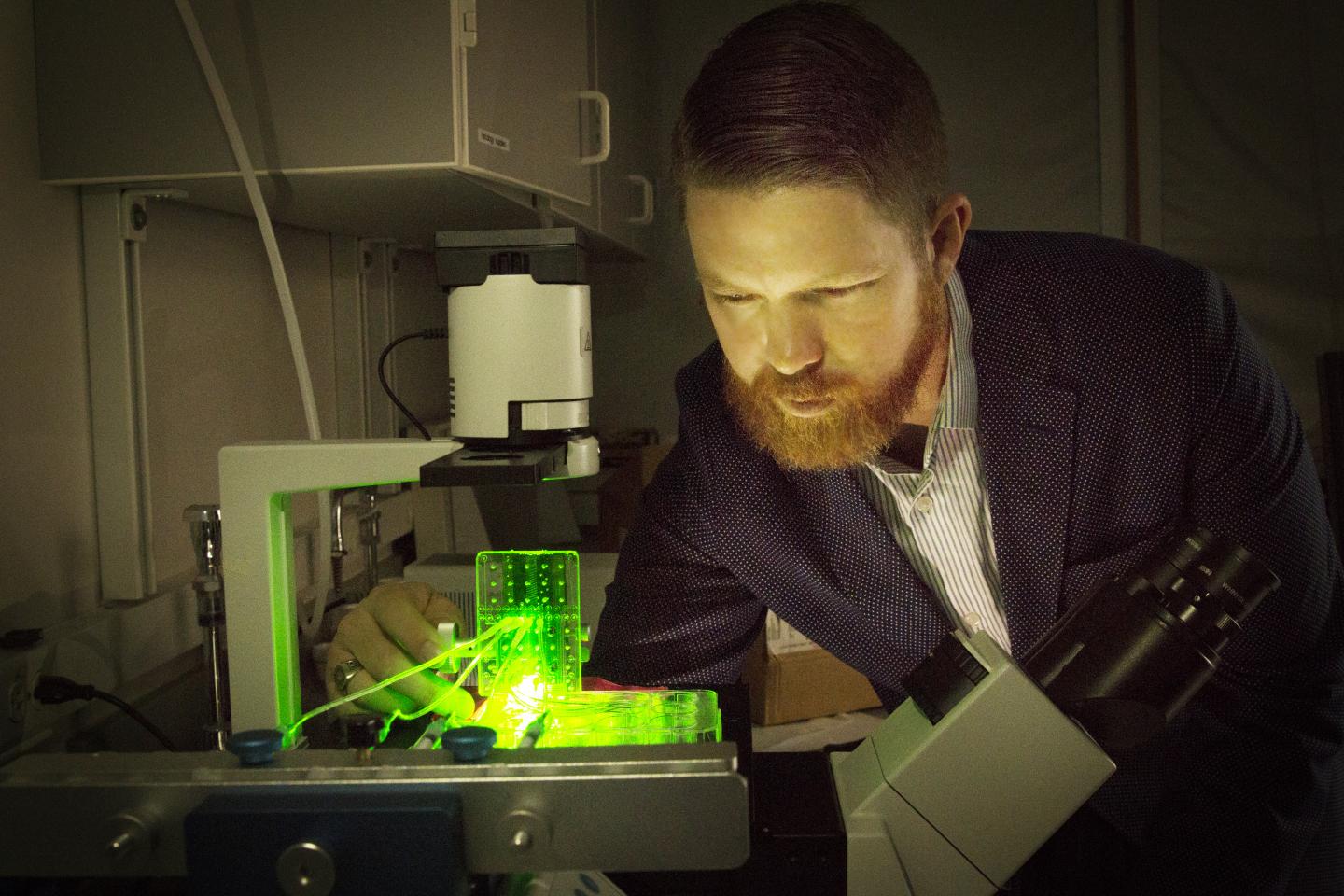

Featured image shows University of Utah biomedical engineering assistant professor Robby Bowles with a customized 3D bioprinter. Photo via Dan Hixson/University of Utah College of Engineering.