The University of North Texas (UNT) has been awarded $10 million by the 86th Texas Legislature towards its Center for Agile and Adaptive Additive Manufacturing (CAAAM). The money will be used to help build the center’s current capabilities, and develop a highly skilled workforce of engineers.

“We are grateful to the Legislature for funding our new center,” said Neal Smatresk, President of UNT. “Through CAAAM, UNT will advance its research and expand its role as a leader in this exciting new technology.”

Advancing additive manufacturing

UNT launched CAAAM in late 2018 under the umbrella of its existing Materials Research Facility (MRF) with the intention of providing students with hands-on educational opportunities in new technologies such as additive manufacturing.

Research conducted at the center will enable the development of smart materials and environmentally friendly technology to advance industrial manufacturing in Texas. Its facilities will also be used to prototype such materials to “globally transform the future of advanced manufacturing.”

“The uses for additive manufacturing have the potential to transform a wide variety of industries — from the oil fields to the operating rooms,” explained Narendra Dahotre, interim vice president for research and innovation at UNT.

“Imagine knowing exactly what you want to create, exactly how much it will cost, exactly how much materials will be needed and exactly how long it will take to complete. Additive manufacturing is the industry’s dream come true.”

The Additive Manufacturing Lab

Prior to CAAAM, UNT used its Additive Manufacturing Lab (AML) to develop metal 3D printing processes. Rajarshi Banerjee, Regents Professor and director of the MRF, stated, “Many universities are involved in 3D printing, but we want to go deeper.”

“We want to understand what is fundamentally different about the same metallic material made using 3D printing technology versus the manufacturing technologies in subtractive manufacturing; What is the difference? Is it good, or is it bad?”

AML integrates selective laser melting (SLM) and laser-based directed energy deposition processes as well as post-process equipment for fundamental and applied research in additive manufacturing.

Want the latest additive manufacturing news? Subscribe to the 3D Printing Industry newsletter and follow us on Twitter and Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

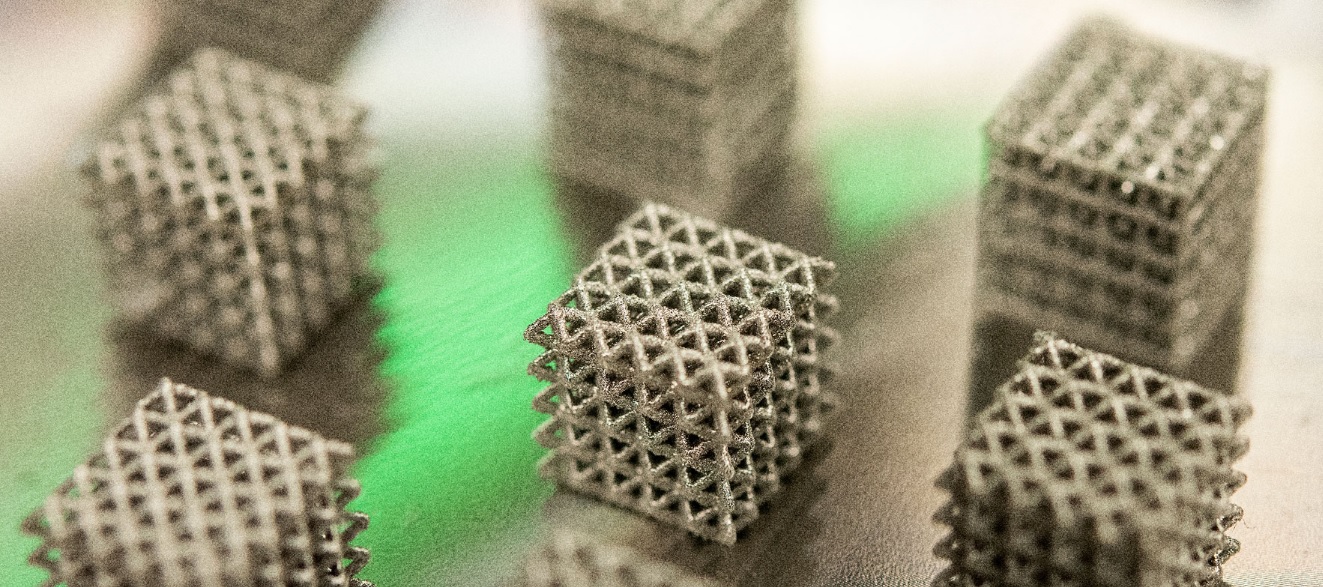

Featured image shows 3D printed structures. Photo via UNT.