Vote now for the 2022 3D Printing Industry Awards.

Vitro3D, a volumetric 3D printing company has raised $1.3M in an oversubscribed seed round led by Buff Gold Ventures. According to the company, this funding can allow the production of prototype printers that manufacture complex 3D objects in seconds.

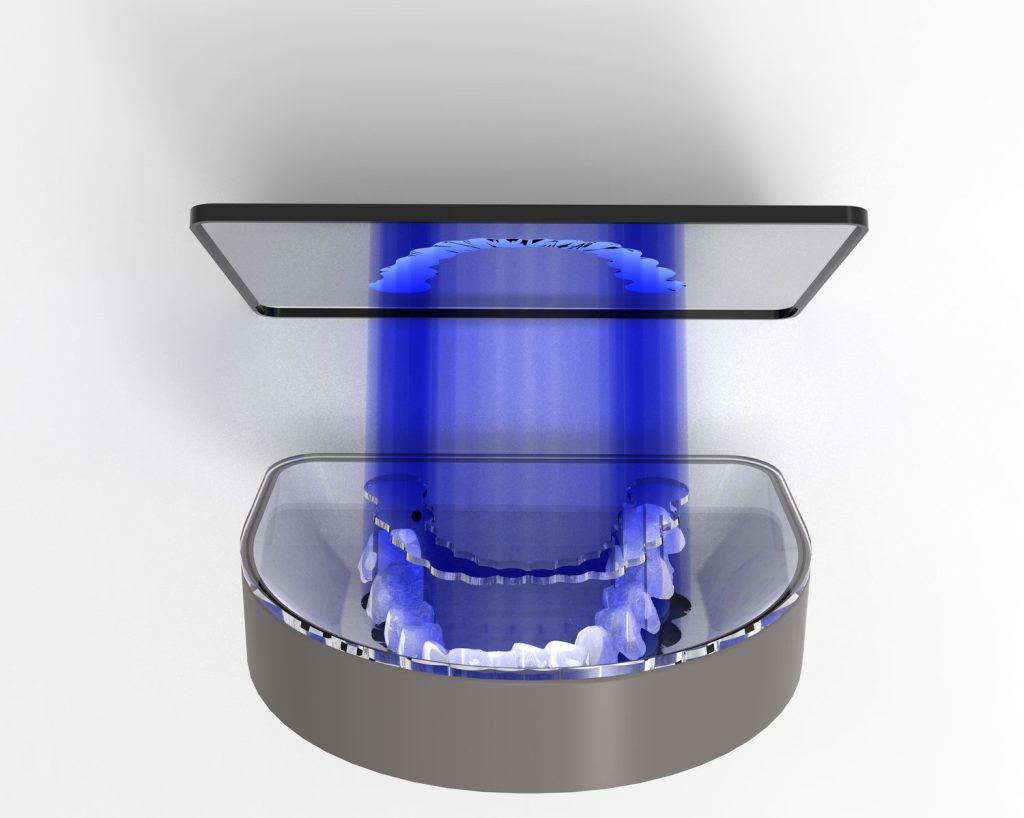

Angel investors the Deming Center Venture Fund, Caruso Ventures, and Rockies Venture Club also participated in this financing round. Vitro3D’s initial focus will be on developing new methods for manufacturing dental aligners and scaffolds for 3D cell culture and tissue engineering. By using its novel cartridge-based geometry, Vitro3D’s advanced volumetric 3D printing technique overcomes the current drawbacks of the photopolymer 3D printing sector and allows for the quick printing of larger and more complex objects.

“Our proprietary volumetric 3D printing technology leverages novel algorithms, proprietary hardware, and materials science allowing us to disrupt industries such as dental aligner manufacturing,” said Dr. Camila Uzcategui, Co-founder, and CEO of Vitro3D. “This funding will enable us to demonstrate the power of our revolutionary 3D printing technology, which offers the potential to change the way complex structures including intricate custom medical products will be rapidly manufactured.”

Overview on Vitro3D

“Vitro3D’s volumetric 3D printer will disrupt how complex and custom products are manufactured in the future,” said Mark Lupa, General Partner of Buff Gold Ventures. “The speed and detail of the products they can produce have broad applicability across multiple industries, and we are excited to work with this great team.”

Vitro3D is also a 3D printing for life sciences company that brings printers to the patient point-of-care. Vitro3D is affiliated with the University of Colorado Boulder, and was spun out of the university. The dental sector is the company’s primary market. The company claims that the dental aligner industry is the largest global user of light-based 3D printing, but the industry’s current production processes are cumbersome, wasteful, and ineffective. A major issue, reportedly, is that instead of 3D printing the dental aligners themselves, a significant amount of time and resources are wasted by printing molds that are then used to produce more aligners

Vitro3D’s goal is to directly print dental aligners using a novel volumetric 3D printing technique that is less expensive, quicker, and simpler to use. The firm addresses the biggest market challenges by enabling dentists to produce custom aligners on-site using the Vitro3D Volumetric Cartridge Printer.

What is volumetric 3D printing?

Volumetric 3D printing, also known as holographic printing or multi-beam additive manufacturing, was created with the objective of achieving fast printing speeds and isotropic mechanical properties. Unlike the traditional layer-by-layer process, volumetric printing creates the entire 3D object at once by irradiating a volume of photosensitive resin from multiple angles.

Earlier, a new volumetric 3D printing technique was developed by researchers from Harvard University and Stanford University that can fabricate resin parts devoid of the use of support structures. The method uses a resin material that contains nanoparticles and only becomes hard when exposed to an extremely focused beam. The researchers have made it possible to print at any point within the resin pool, not just at the surface layer, by varying the laser’s focus throughout the resin vat.

Previously, researchers from Berlin Aldershof Science and Technology Park were working on a dual-color volumetric 3D printing technique that, in their opinion, outperforms stereolithography and other used 3D printing technologies. Together with IRIS Aldershof chemist Stefan Hecht and physicist Martin Regehly, Dirk Radzinski, the founder of Berlin Aldershof startup company Xolo, led the development of this volumetric printing technique known as Xolography. This method, which addresses speed, surface quality, and material properties, outlines three “serious limitations” of conventional resin printing, according to its developers.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Volumetric 3D printing in progress. Image via Vitro3D.