3D printing for bone healing and implants is the subject of a new 5-year project at the University of Arizona (UA).

With a $2 million grant from the U.S. Department of Defense, a study will be launched that aims to heal bone fractures using 3D printed scaffolds and adult stem cells. The project will be led by Dr John A. Szivek, PhD, a professor and biomedical engineer at the university’s College of Medicine in Tucson.

Dr. Szivek, describes the particular problem he is seeking to address, “Imagine an impact that causes half of a long bone to shatter so that it can’t be put back together – no current surgical treatment can ensure that kind of injury will heal,”

“This is a really big problem for the military, where explosions or combat injuries can cause big bone defects.”

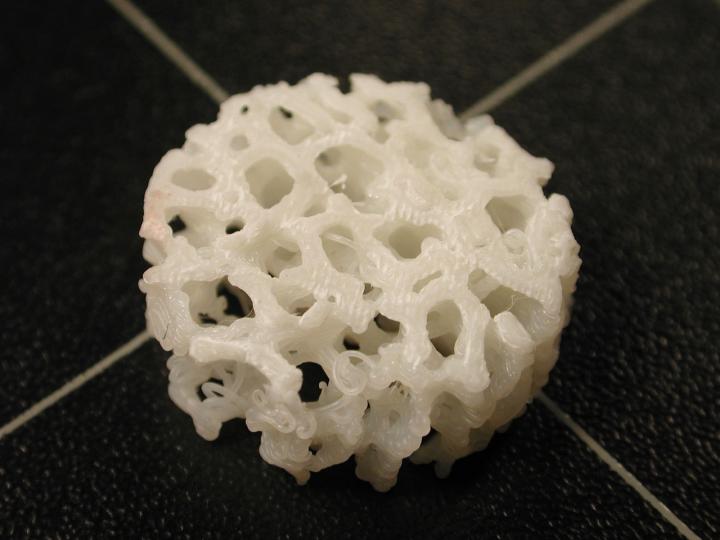

Working in conjunction with the UA’s Department of Orthopaedic Surgery, 3D printed plastic scaffolds sufficient to replace large areas of missing or damaged bone will be created. By filling the scaffolds with known agents that promote healing – in this case calcium particles and adult stem cells – it is anticipated that damage can be repaired at a faster rate.

Early results are promising, with pilot studies verifying the technique, “We achieved complete bone formation, covering a large bone defect in about three months. Now we want to make that healing process even faster,” said Dr. Szivek.

Embedded sensors to monitor impact of exercise on bone healing

Other factors known to aid recovery will also be studied. These include exercise, “Studies have shown that exercise makes your bones grow, so maybe we can make bone on our scaffolds grow even faster with exercise”. By embedding sensors within the 3D printed bone scaffolds the implants will monitor activity levels of a sample group.

UA President Robert C. Robbins, M.D. described the project as, “an incredible example of the kind of innovative research that is made by possible by technological advancement through the convergence of the biological, physical and digital worlds, and exactly the kind of project that demonstrates how the UA is a leader in cutting-edge solutions to difficult challenges,”

“The work that Dr. Szivek and his team are doing to help these individuals is a great example of using new technology to significantly improve quality of life for patients. I am confident their unique research will lead to the development of more effective treatments to repair critical bone injuries.”

In addition to improving the patient outcome of external traumatic incidents, the research may also find application for, “patients with bone cancers that are removed operatively.”

Elsewhere, University of Glasgow scientists have previously used 3D printing and the protein BMP-2 to create synthetic bones for a dog. While the CT-Bone product developed by Dutch company Xilloc, is 3D printed with calcium phosphate, the material found in naturally occuring bone.

For all 3D printing news, subscribe to our newsletter. You can also follow us on Facebook and Twitter.

Visit 3D Printing Jobs to take your career to the next level.