Californian software and material producer Uniformity Labs has closed a $38.35 million Series B financing round, the proceeds of which it will use to drive the expansion of its production capabilities and increase the development of additional specialized materials.

The funds will also be plowed into growing the firm’s senior team, particularly within the area of sales and marketing, which will be ramped up over the course of this year.

“This marks a significant milestone in our next phase of growth as we scale our game-changing metal feedstock and print applications businesses to greatly improve the 3D printing value proposition for major manufacturers,” said Adam Hopkins, Founder and CEO of Uniformity Labs.

“What’s more important about this round is the level of commitment from new financial and strategic industry investors, which stands as an important endorsement of our technology and business model.”

Uniformity Labs

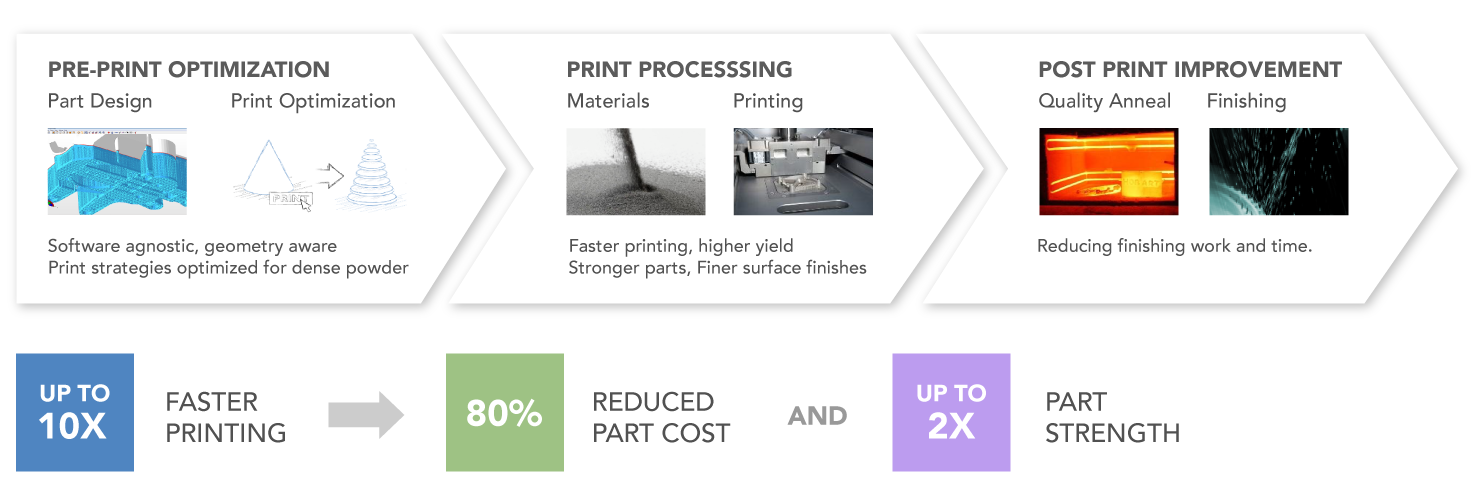

Founded in 2014, Uniformity Labs develops feedstock materials and print processes that aim to provide significant cost savings, speed, and quality improvements to 3D printers. The firm provides metal materials and proprietary alloys for powder bed fusion (PBF) and binder jetting, among other platforms.

Uniformity’s powders possess high relative densities approaching that of the densest crystalline particle packings, while retaining low viscosity and the ability to flow. Reportedly, the materials can reduce porosity to between 15-30 percent, in comparison to 40-50 percent porosity of typical powders. Meanwhile, its part fabrication software optimizes parts for additive manufacturing and enables high-scale production of printed parts via PBF and binder jetting platforms, thanks to high throughput and lower costs.

Together, Uniformity’s technology and refined feedstocks enable 3D printers to operate at faster speeds with increased reliability and decreased finishing requirements.

At the end of last year, Uniformity Labs appointed former General Motors executive Alan Batey as an advisor to its senior management team to provide a “unique perspective” on the company’s scaling up.

Fueling growth

The funding round saw Uniformity Labs’ existing investors, one of which is intellectual property (IP) commercialization firm IP Group, joined by new financial and strategic partners as the company enters a new growth phase.

The firm will use the funds to ramp up the production capabilities and development of its specialized 3D printing materials, and will also significantly expand its senior team over the course of 2021.

“As its founding investor, IP Group is excited to see Uniformity Labs poised to disrupt the AM market,” said Michael Burychka, CEO of IP Group. “Adam Hopkins and his team have done a tremendous job developing the core technology created in Professor Sal Torquato’s labs at Princeton University to unlock the potential of powder-based manufacturing.

“UL is an excellent example of our focus on supporting the commercial development of innovative hard science from premier research institutions like Princeton.”

The funding round also includes an investment from global investment management firm Orion Resource Partners to finance Uniformity Labs’ plant construction.

Oskar Lewnowski, Chief Investment Officer at Orion, said: “Orion is pleased to make its first investment into the additive manufacturing and metals atomization industries through Uniformity Labs. We look forward to supporting their growth within the rapidly evolving industry.”

ubscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Uniformity’s powder, processes, and software have delivered economically viable print solutions for customers across a range of industries. Image via Uniformity Labs.