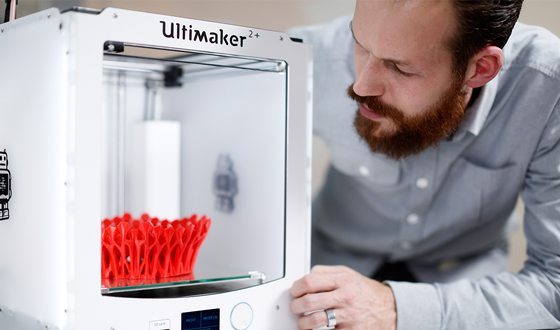

Industry leaders in open source 3D printing content, Ultimaker, recently announced the release of four new materials slated for 3D printing use with the Ultimaker 2 family of products. According to the Ultimaker team, the new materials were developed to yield the highest level of properties necessary for enterprise-grade outputs in the field. With great potential for use by product designers, manufacturers, tinkerers and more, the new releases are said to expand the breadth and depth of printing options.

As industrial 3D printing continues to gain popularity, users need materials that are exclusively developed and optimized for their purposes. Now, users are guaranteed durability, strength and chemical resistance in their products thanks to Ultimaker’s development of these new materials. Ultimakers offers their materials at affordable prices, to ensure all “customers are able to manufacture functional prototypes, end-use parts and tools” that live up to demanding industry standards. According to Siert Wijnia, Founder and CTO at Ultimaker, there be even more to come:

“As we continue to revolutionize Ultimaker’s offerings, both with the physical printer capabilities and printing materials, our enterprise customers remain at the center of our reasoning. The four new materials are just the beginning of enhancements we will introduce throughout the remainder of 2016 and we look forward to moving the 3D printing industry forward with impressive innovations.”

Ultimaker’s newest materials are manufactured to cover a wide range of product applications in the highest print quality available. These materials include:

- Ultimaker CPE+ (co-polyester) – handles temperatures up to 100 ºC, is chemical resistant, tough and dimensionally stable.

- Ultimaker PC (polycarbonate) – offers a great print quality, heat resistance up to 110 ºC, mechanical strength and toughness.

- Ultimaker Nylon (polyamide) – strong, abrasion-resistant, durable and engineered for low moisture sensitivity.

- Ultimaker TPU 95A (thermoplastic polyurethane) – Shore-A hardness of 95 and an elongation of up to 580% at break. It’s suitable for applications that require slight flexibility, wear and tear, and chemical resistance.

About Ultimaker

From the very beginning Ultimaker’s vision has been to make 3D printing accessible to all. It is why all their desktop printers are extremely quiet, fast, accurate, reliable and effortless to use. Such a commitment has been embraced by professionals and novices alike. This has also helped Ultimaker to become one of the most successful and reliable open source 3D printing companies in the world. Most recently, Ultimaker was awarded “Best in Shootout” 2015 from the established Make Magazine, Editors’ Choice by Digital Trends and Best Consumer Product at the 3D Printshow Global Awards 2014.

Featured Image courtesy of Ultimaker