TRIDITIVE, a Spanish 3D printer manufacturer, has announced a strategic collaboration with Elnik Systems, a U.S. manufacturer of metal injection molding (MIM) equipment. This partnership will provide TRIDITIVE’s SCALADD consortium with MIM debinding furnaces and tools.

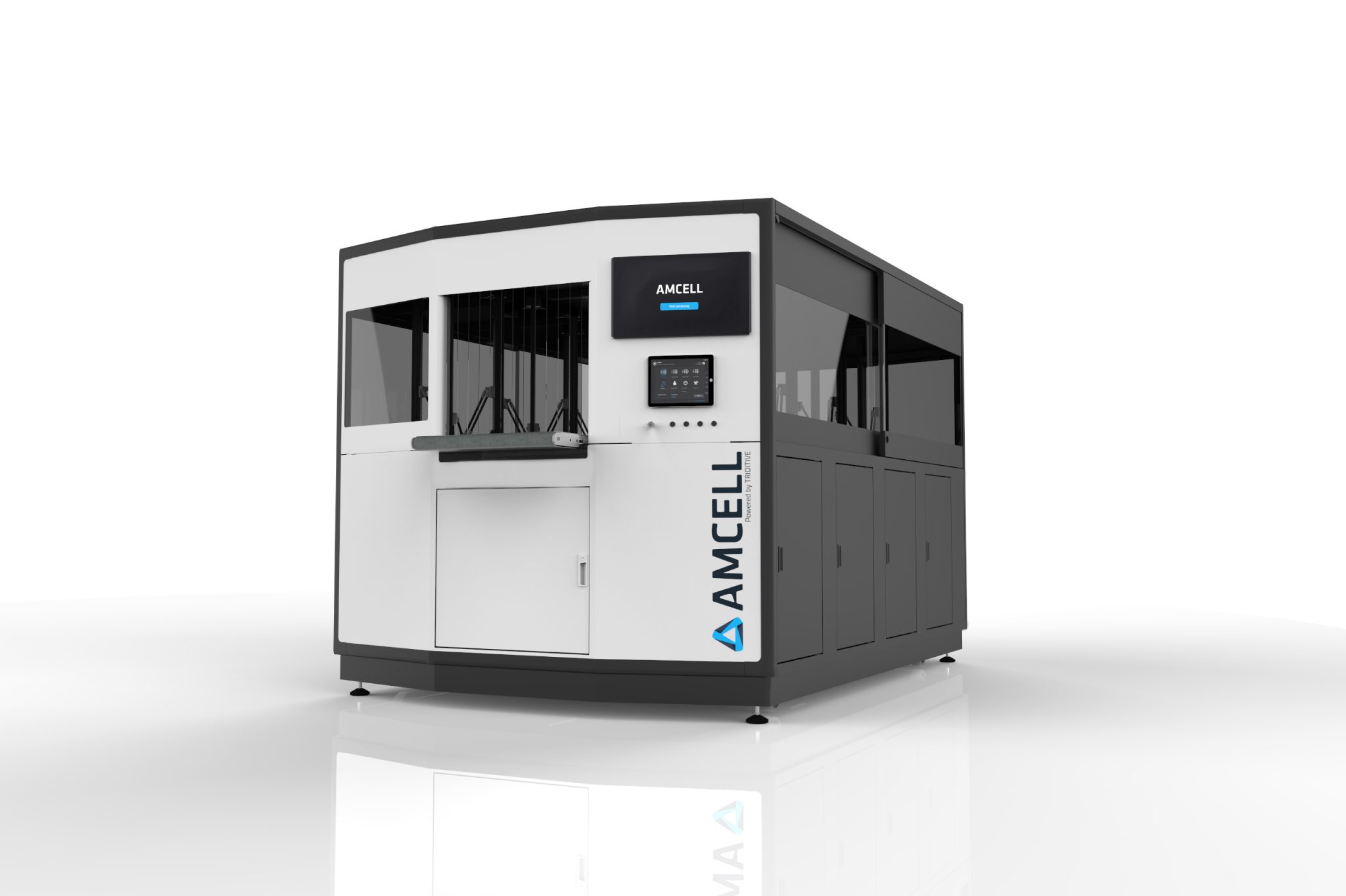

Last year, the company established SCALADD, an additive manufacturing center providing high capacity turnkey services. This center houses several AMCELL 3D printers, hybrid systems for metals and polymers, designed for mass production.

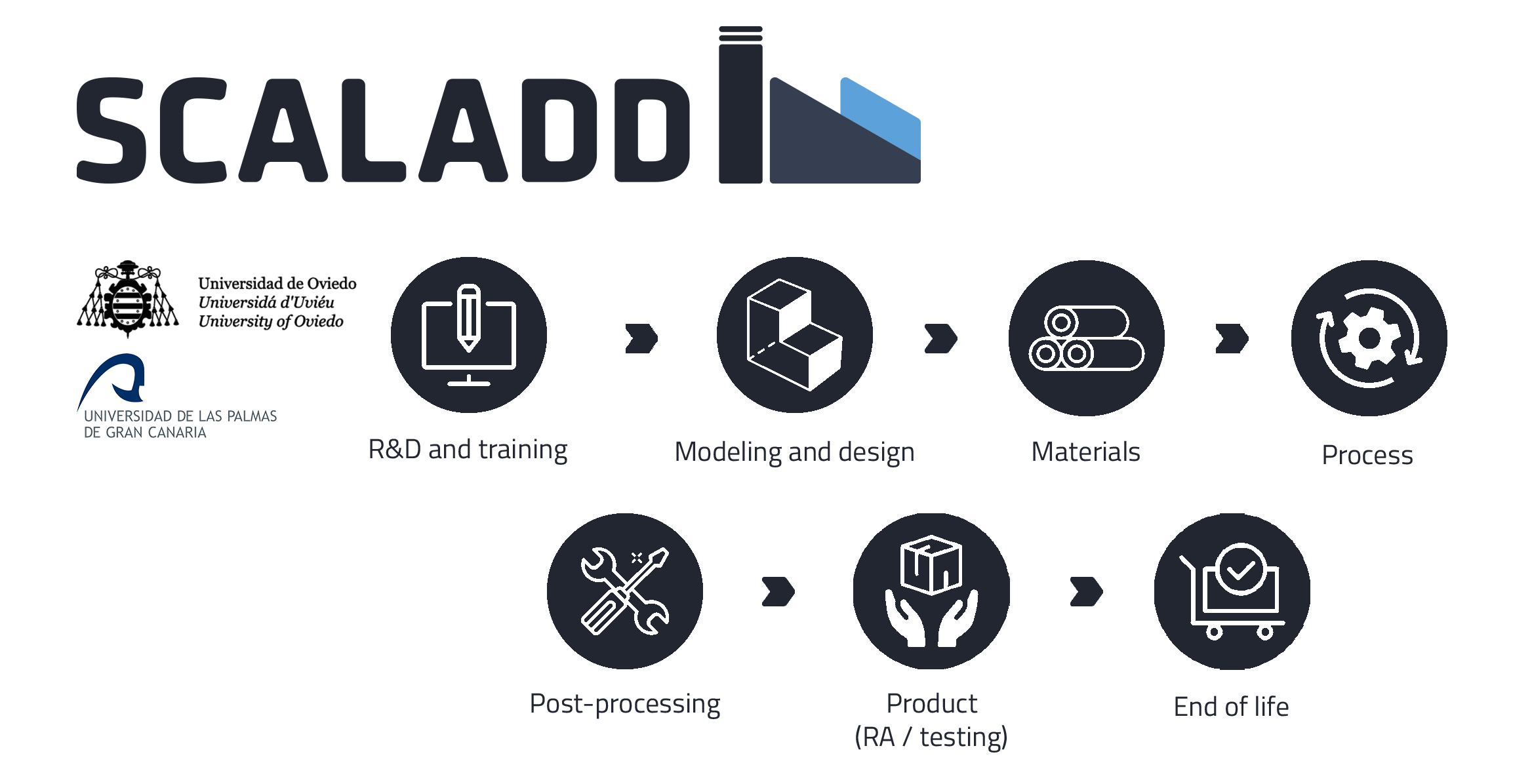

The SCALADD consortium, which aims to expand the adoption of metal additive manufacturing, currently includes the University of Las Palmas de Gran Canaria (ULPGC), the MediaLab of the University of Oviedo, and ECRIMESA Group, a manufacturer MIM parts.

“We have a clear objective [for] working with Elnik Systems: to demonstrate that AM is ready for mass manufacturing in metals using AMCELL automated machine,” said Mariel Díaz Castro, CEO of TRIDITIVE.

High volume metal additive manufacturing

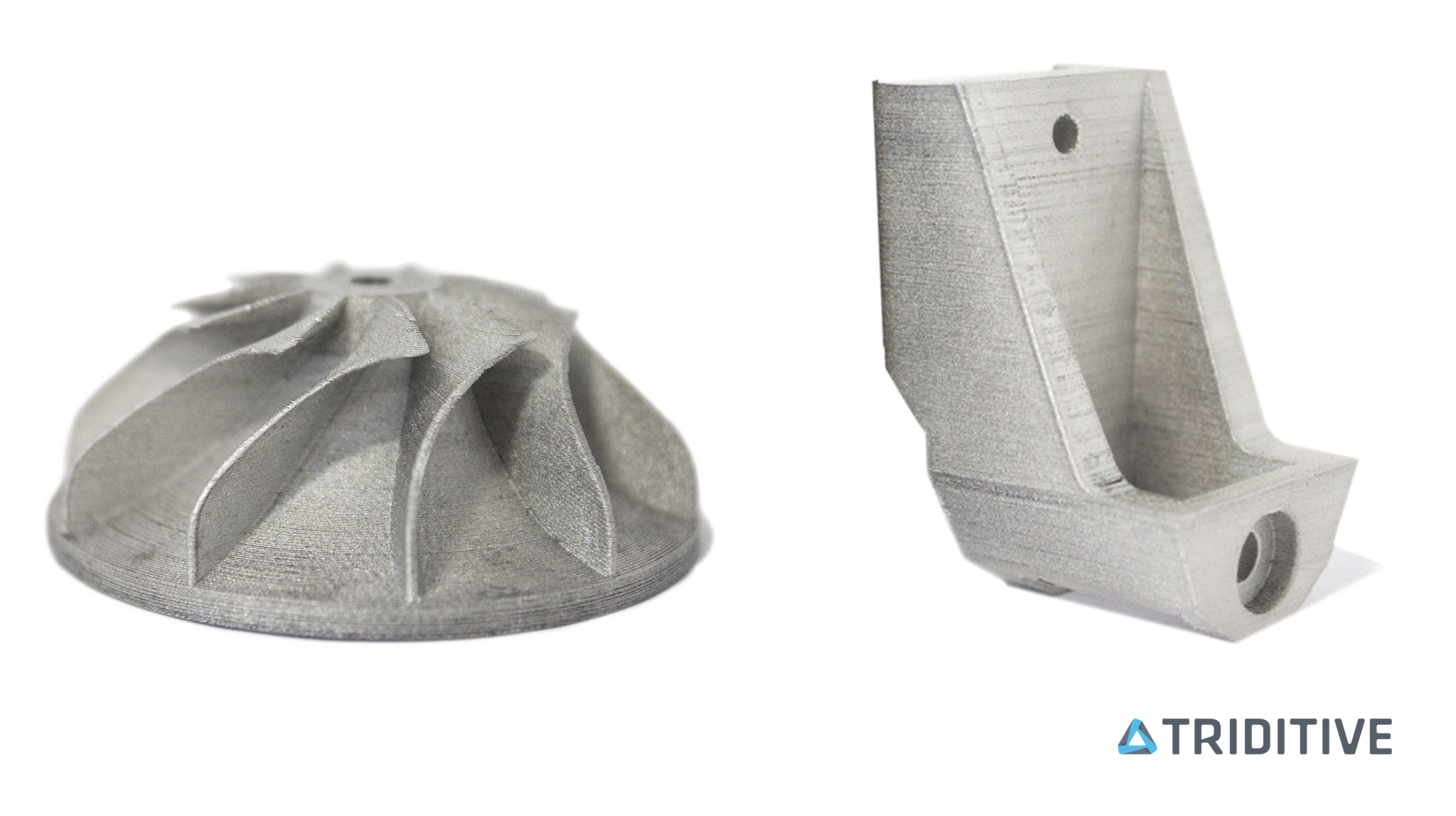

During Formnext 2018, TRIDITIVE announced its intentions to accelerate the adoption of serial additive manufacturing of metal parts. As such, the company began using the Ultrafuse 316LX filament, from BASF a German chemical company.

Made from a polymer infused with stainless steel particles, this material works in tandem with the AMCELL 3D printer, to produce a metal part with “porosities similar to that typically obtained from MIM,” added Castro.

AMCELL is a conveyor belt 3D printer, capable of producing up to 10,000 parts per month. Enabled by its control software and remote monitoring, the AMCELL is making additive manufacturing a viable solution for continuous high volume manufacturing. SCALADD intends to have a production capacity of up to 30,000 parts per month with such systems.

The SCALADD consortium

As members of the SCALADD consortium, the ULPGC is working to provide additive manufacturing training in the processability and characterization of polymers, with hopes to expand industrial use of this technology.

In addition, the MediaLab of Oviedo University plans to create links between engineering students and SCALADD by developing specialized training in additive manufacturing and research projects. Castro explained:

“We share a common goal attempting to implement new training methods that may be implemented by Universities, but also provide the manufacturing industry with new professionals with skills in AM this technology will help the manufacturing industry to innovate and to be more competitive.”

“[The] collaboration with ECRIMESA will extend the potential market for MIM industry and will guarantee the possibility to provide the industry our high level of metal production with the highest quality.”

All members prior to Elnik Systems joined the consortium in December 2018.

Nominations for 3D Printing Industry Awards 2019 are open. Let us know the enterprises, technology, and individuals leading the additive manufacturing sector.

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows the SCALADD center. Image via TRIDITIVE.