Our next article in the State of Resin 3D Printing series contains insights from a scientist with a deep understanding of additive manufacturing and material science.

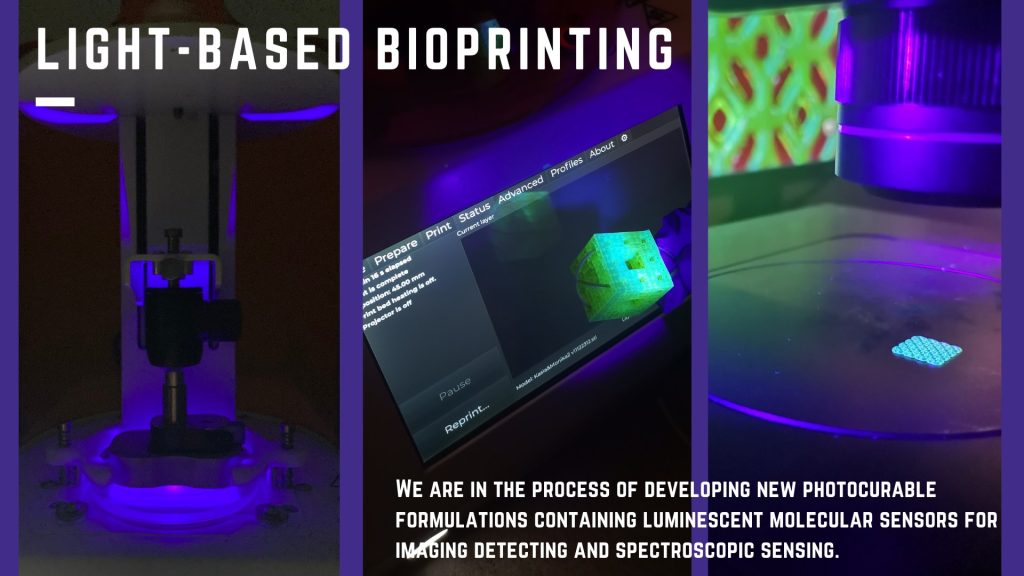

Professor Joanna Ortyl, PhD, DSc., Eng., runs the Ortyl Applied Research Team at the Cracow University of Technology. Projects include Opus, looking at carbon dots and applications in photopolymerisation, and the development of a 3D printer to work with nanocomposites. Research spans bioprinting of hydrogels, cationic and free-radical photoinitiators to 3D-vat printing.

Professor Ortyl is also CEO of Photo HiTech and Photo4Chem, enterprises active in science and engineering with expertise in photopolymers.

3DPI: What do you consider the next technology hurdles for photopolymer-based 3D printing to overcome?

Joanna Ortyl: The next technological hurdles that photopolymer-based 3D-VAT printing technology must overcome are primarily the ability to print integrated circuits and electronics. For example, to obtain highly conductive materials combined with insulators. Maybe even 3D printing and combining semiconductors with conductors and insulators in the future. Moreover, all this while maintaining the precision and resolution of 3D printing at 1um or below. Another technologically important issue is the possibility of 3D printing magnetic materials that could be positioned by a magnetic field. In the future, one might be tempted to 3D print from micromotor photopolymers. Imagine – a small rotor rotating in an external magnetic field, obtained by 3D printing.

3DPI: What applications of vat photopolymerization do you see as under-developed by the market, and why?

Joanna Ortyl: I consider a photo-curable composite or nanocomposite resins to be particularly underdeveloped by the current market. 3D printing of composite materials offers excellent opportunities, but it is not easy to obtain a working material that exhibits an ordering of the filler, such as fibres aligned in one direction.

I see photopolymerization technology in 3D printing, especially in obtaining conductive materials. In this case, it is necessary to expand the perception of light as a source of the photopolymerization process and not be limited only to the range of visible spectrum but also to the NIR range. Extending the functionality of the light spectrum to the NIR range, e.g. 980 nm, gives the possibility to use completely new materials for the role of initiator systems. In addition, LED light sources should not be limited, but new technological solutions in electronics and optics should be taken into account.

3DPI: Where are opportunities for materials development in regards to vat photopolymerization technology?

Joanna Ortyl: Photopolymerisation technology in 3D printing allows you to freely modify the composition of the raw material from which we print, to the extent that is not possible with other 3D printing techniques that use thermal processing of materials (FDM, SLS printing). The photopolymerization technique allows processing materials at temperatures close to room temperature, making it possible to modify photo-curable resins by adding temperature-sensitive components that would thermally decompose in standard 3D printing techniques (FDM, SLS). Thus, using the photopolymerization technique, it is possible to introduce materials for 3D printing that are not suitable for use in other techniques such as FDM SLS. Moreover, due to the nature of energy transport in the form of light, the use of photopolymerization allows the use of 3D printing devices in different media such as vacuum, or water environments, where the use of classical 3D printing techniques FDM or SLS is not possible due to the transfer of energy in these techniques in the form of thermal energy.

Make sure you don’t miss the results of our of 3D printing with resin survey. Sign up for our free newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry. Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the Ortyl Applied Research Team. Photo via Ortyl Applied Research Team.