Tekna, one of the few companies in the world to produce 3D printing powders by gas plasma atomization, has signed an MoU Luxembourg steel specialist Aperam.

Together the companies have agreed to co-develop spherical metal powdered feedstock for use in 3D printing and metal injection molding (MIM).

The news follows Tekna’s $5.5 million investment in the expansion of production facilities in Sherbrooke, Québec.

Tekna and Aperam metals

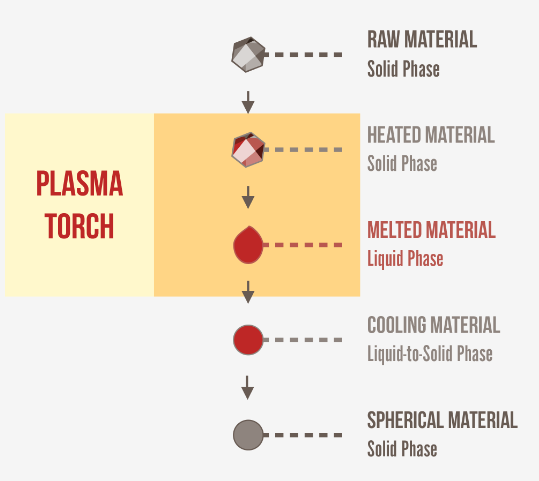

Gas plasma atomization at Tekna ensures the production of powders with a controlled grain size and sphericity with a high level of purity. For additive manufacturing in particular, its range of powder encompasses Ti64 titanium, Tungsten Carbide, Tantalum, and Molybdenum, a common addition to steel and stainless steel alloys. In addition to spherical powders, the company also makes nanopowders.

Since the expansion of its facilities in Quebec, Tekna is on track to increase the production of both its powdered products to over 1000 tonnes per year.

Aperam, on the other hand, produces steel and stainless steel in bars, strips, wire rods and plates. In addition to its Luxembourg headquarters, the company has sites across 18 European nations, Russia, Asia, the Middle East and North and South America. This includes 2.5 million tonnes of flat stainless steel capacity in Europe and Brazil.

Metal powder strategy

This new partnership with Aperam is parts of a wider, growth strategy at Tekna, as Luc Dionne, CEO of Tekna Plasma Systems, comments, “This agreement is a major step in Tekna’s growth strategy in the markets of additive manufacturing.”

For Aperam, Tekna offers the opportunity for the company to expand its reach beyond its existing steel products. “We are very proud of today’s agreement with Tekna, which is part of our strategy to further transform our business and address the next generation needs of our customers through new technologies,” says Timoteo Di Maulo, CEO of Aperam, “This collaboration also enables us to further consolidate our leading position in the Nickel alloys and speciality steels markets.”

Notable competitors of Tekna, and now Aperam, in the plasma atomized metal powders market include AP&C, now a part of GE Additive, and Pyrogenesis, headquartered in Québec, Canada.

Recently, AP&C teamed up with the National Research Council of Canada (NRC) to develop a method for anaylzing metal additive powders, and Pyrogenesis is currently in the midst of its ‘industrialization plan‘ having seen the completion of a new metal powder production facility.

For all the latest materials, software and hardware news subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter. For new, professional opportunities in the industry, search 3D Printing Jobs.

Featured image shows Tekna metal powder. Image Tekna