Watch the 2022 3D Printing Industry Awards Live on Tuesday, 13th December: subscribe and enable notifications.

3D printer manufacturer Stratasys announced that Team Penske, a leading motorsports company has purchased a new Stratasys Neo® 800 3D printer.

Team Penske’s first Stratasys stereolithography-based 3D printer will be employed to quickly print scale model parts for aerodynamic testing. Matt Gimbel, Production Manager at Team Penske said, “As additive manufacturing’s applications continue evolving in racing, Stratasys continues to help us rapidly improve race performance ahead of the competition so we can turn ideas into parts and get them onto the racetrack faster than ever before and with greater reliability than ever before.”

“We can now make parts in ways not possible through traditional manufacturing,” added Production Manager at Team Penske.

How does Stratasys Neo® 800 3D printer help Team Penske in chasing victory?

“With over 500 wins, Team Penske’s commitment to excellence is unrivaled in the motorsports industry, and achieving new heights of performance means constantly asking how things can be done better,” said Pat Carey, Senior Vice President of Commercial Development at Stratasys.

Gimbel quoted the open materials model for the Neo printers as a major benefit, in addition to the high quality of the surface finish and the reliability of the Neo system. Allowing Team Penske to source materials from any supplier gives the organization maximum material selection flexibility. Furthermore, the Neo800 3D printer’s large build volume (800 mm x 800 mm x 600 mm) enables them to print larger parts with less time spent hand sanding, sectioning and joining parts together for wind tunnel testing.

This purchase is constructed on a technical alliance with Stratasys that began in 2017. Stratasys has previously provided Team Penske with a wide range of 3D printers based on FDM® and PolyJet™ technology for prototyping, tooling, fixturing, and end-use parts in cars and pit equipment.

“As one of their chief partners in additive manufacturing solutions, we are committed to providing more winning solutions tailored for the racing industry than anyone else in the industry so Team Penske can capture more checkered flags than any other racing organization in the world,” added the Senior Vice President of Commercial Development at Stratasys.

Additive manufacturing sector’s automotive portfolio

Toyota, the Japan-based automotive manufacturer, began collaborating with SOLIZE this year to 3D print spare car components on-demand. Toyota utilized HP Multi Jet Fusion 3D printing to manufacture stock parts as part of a project that began last year, before selling them alongside conventionally produced spares. Using the technology enabled the company to optimize the designs and lead times of newly developed parts, while simultaneously providing it with improved short-run production capabilities.

Furthermore, leading sports car manufacturer Porsche strategically invested in 3D printer manufacturer INTAMSYS to investigate additional ways in which additive manufacturing technology can be used in the automotive sector. Although the exact investment amount by Porsche Ventures remains unknown, the car manufacturer asserted that 3D printing is an “integral part” of future digital manufacturing technology and thus deserves “long-term and continuous” input. Porsche intended to use the investment to digitalize and enhance its product manufacturing process, as well as to expand the usage of additive manufacturing in the luxury car sector.

Elsewhere, the 3DPI team interviewed Ellen Lee, Technical Leader of AM Research at Ford. Lee is heavily involved in the firm’s additive manufacturing R&D and as such, she sees both the technology’s benefits and the ‘gaps’ that prevent its wider adoption. “AM has quickly become an essential part of our design and engineering validation process, and continues to be used for more and more functional prototype testing as the technologies advance,” explains Lee. “We now also use AM technologies for the direct production of end-use parts, both for our manufacturing lines as well as for our vehicles.”

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

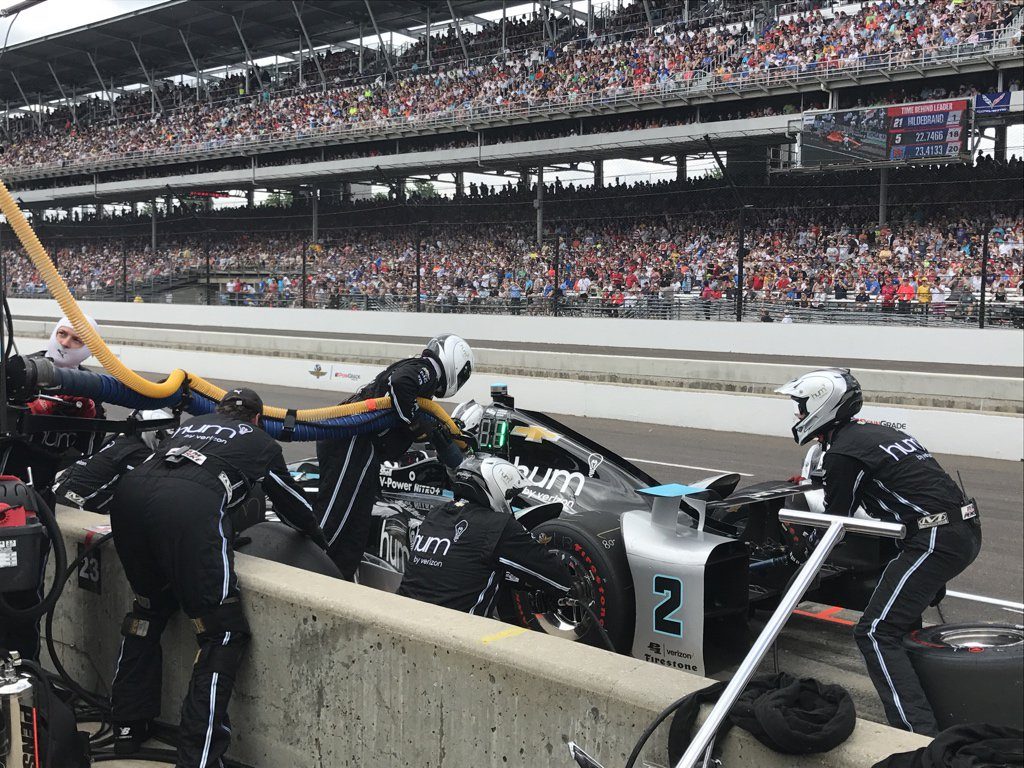

Feature image shows Will Power won Team Penske’s 17th INDYCAR Series championship in September. Team Penske has been expanding its 3D printing capabilities with Stratasys to get better parts onto the racetrack faster than ever. Image via Stratasys.