Swiss advanced satellite products and Radio Frequency (RF) systems provider SWISSto12, has delivered three fully integrated RF Antenna Feed Chains to Northrop Grumman Corporation for the GEOStar-3 commercial satellite program.

According to the company, the qualification program for these feed chains was completed in January 2024. Scott Wolf, Managing Director of St12 RF Solutions, the US entity of SWISSto12, expressed the company’s satisfaction with the first delivery to Northrop Grumman of advanced Radio Frequency Antenna Feed Chains for the commercial GEOStar-3 program.

Wolf noted that the Radio Frequency and HummingSat geostationary SmallSat business has garnered over $200 million in customer orders to date, underscoring the company’s mission to enhance existing payload capabilities to protect better and connect every corner of the world.

Optimizing performance and weight with RFAM

The feed chains are comprehensive monolithic assemblies that integrate diplexers, filters, polarizers, horn apertures, and mechanical interfaces. These components are produced as a single unit using SWISSto12’s proprietary Radio Frequency Additive Manufacturing (RFAM) process. This innovative approach enables precise design optimization to reduce size and weight while meeting stringent RF performance and qualification criteria for the GEOStar-3 program.

Ensuring alignment with mission specifications, the feed chains are set for integration into GEOStar-3’s payload. Notably, this marks St12 RF Solutions Inc.’s first SatComm contract to deliver SWISSto12’s solutions to US clients. Following the successful completion of Northrop Grumman’s qualification program in January 2024, the GEOStar-3 launch is slated for later this year.

Established in 2011, SWISSto12 has been using advanced AM tailored for RF applications, garnering traction within the aerospace sector. Conventional RF product designs faced challenges due to manufacturing constraints impacting performance, weight, size, and cost.

SWISSto12’s RFAM technology allows for the production of intricate and non-traditional designs that were not feasible before. By improving manufacturing tolerances, surface finishes, plating techniques, and RF designs, SWISSto12 aims to enhance RF performance, achieve size and weight efficiencies, and maintain competitiveness in its products.

3D printed satellite antennas

As observed previously, AM is being increasingly used in satellite antenna production due to its ability to create customized, lightweight designs with complex geometries. This method enables rapid prototyping, optimizing antenna performance through material selection and integrated design.

For instance, 3D printer manufacturer 3D Systems collaborated with Australian satellite developer Fleet Space to produce RF patch antennas for Fleet Space’s Alpha satellites. Using the DMP Flex 350 metal printer, 3D Systems’ Application Innovation Group (AIG) facilitated the rapid transition from design to small batch production within three weeks. Fleet Space had planned to acquire its own DMP Flex 350 for antenna manufacturing at its headquarters in Adelaide, aiming to support its Alpha constellation which was set to launch in 2023.

Back in 2022, Mitsubishi Electric developed a novel approach for freeform 3D printing of satellite antennas in orbit using a specially formulated liquid resin capable of photopolymerization by the sun’s ultraviolet (UV) rays. This technology aimed to enable the fabrication of large high-gain antenna reflectors and other large-format parts directly in space, surpassing the size constraints of satellite fairings.

By avoiding the complexities and risks associated with traditional deployment methods, such as spring-loaded mechanisms, Mitsubishi Electric sought to reduce satellite weight, and launch costs, and enhance signal relay capabilities for SmallSats and CubeSats.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

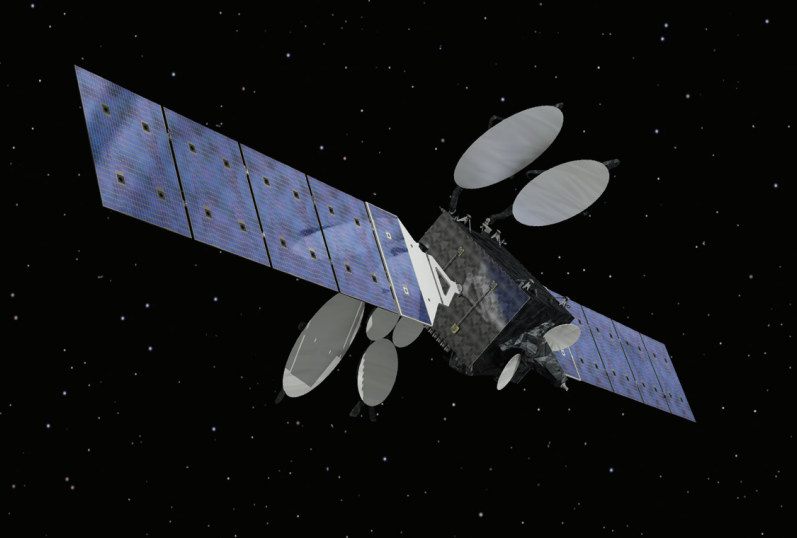

Featured image shows SWISSto12’s RF Feed Chains. Image via SWISSto12.