Industrial machinery manufacturers Sumitomo Heavy Industries (SHI), headquartered in Tokyo, Japan, has bought Massachusetts additive manufacturing developer Persimmon Technologies for ¥3.6 billion ($33 million).

The acquisition will expand Sumitomo’s product lines and explore new opportunities in the electric hybrid motor field as, for example, in steering and brake parts for cars and motorbikes.

Smaller, lighter, faster, stronger

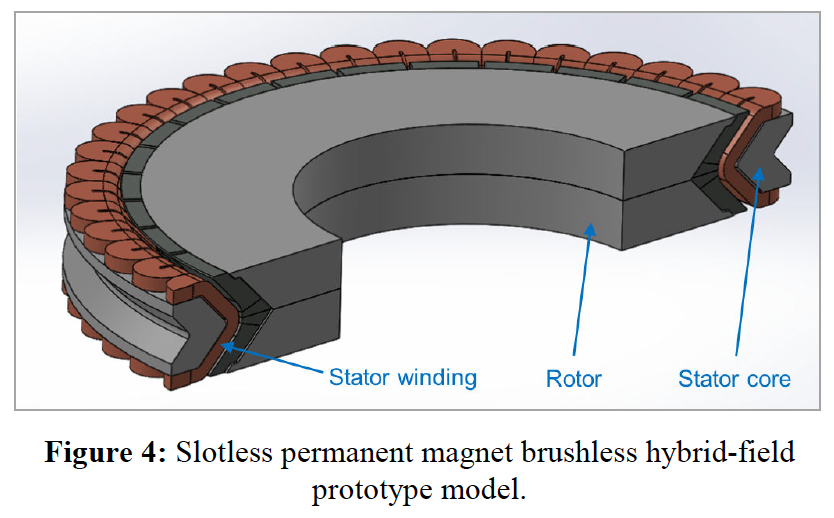

In a typical electric motor the winding core is made of laminated silicon steel. This laminated core limits the performance of the motor as it doesn’t allow a current to move in every direction. It also takes multiple steps to make it, hindering the production process. Persimmon Technologies simplifies the traditional method and claim improved performance using a spray-formed 3D printing technique.

Spray-forming from Persimmon makes a winding core from consecutive layers of soft magnetic composite material. The metallic material is sprayed as droplets, making use of micro spaces in-between for insulation and lightness. As explained by Persimmon in a presentation at the 2016 ASME conference in North Carolina, “the spray-formed soft magnetic material enables smaller, lighter motors with higher power output and better energy efficiency.” The actual figures for a spray-formed motor, when compared to a conventionally made electric motor, results in approximately 40% higher power densities, with energy losses up to 15% lower.

The electric movement

Long snubbed because of their performance relative to fuel-driven counterparts, electric and electric-hybrid vehicles have risen higher on the list of priorities for many manufacturers. Michigan-headquartered Ford Motor Company are one leading automotive manufacturer taking this electric intiative to heart. With the help of 3D printing, the company are moving towards a greener, smarter future of wireless charging, electric cars.

Self-driving cars are also a popular vision for future vehicles. Some car manufacturers, such as Mercedes-Benz, are also looking to 3D printing to solve design challenges this type of car.

For more news on 3D printing for the automotive industry sign up to the 3D Printing Industry newsletter, and follow our active social media sites.

Don’t forget to vote in the first annual 3D Printing Industry Awards.

Tickets for the 3D Printing Industry Awards are also now available here.

Featured image: Looking up through the center of the Sumitomo Building in Tokyo’s Shinjuku district. Photo by Chris Brown, zoonabar on Flickr.