3D printer manufacturer Stratasys has improved the capabilities of its J750 Digital Anatomy 3D printer to produce models that better replicate porous bone structures, fibrotic tissue, and ligaments.

Receiving a medical upgrade last year, the Digital Anatomy printer initially sought to mimic soft cardiology tissues such as hearts and blood vessels. Now, the printer’s capabilities have been extended to include biomechanically accurate orthopedic applications thanks to an upgrade of its Digital Anatomy software.

“We believe that better preparedness leads to better clinical outcomes,” said Osnat Philipp, vice president and global healthcare team leader at Stratasys. “The mechanical properties of bone are so fundamental to the ability of our skeletons to support movement, provide protection for our vital organs and ultimately affect our quality of life.

“Being able to 3D print models that are biomechanically accurate and unique to each patient is critical to that preparation.”

3D printing bone models

Despite increasing demand for bone models, shortcomings remain within traditional off-the-shelf model offerings in regards to patient-specific characteristics and biomechanic realism. Progress is being forged in this area, however, as 3D printing technology, materials, and software continue to see improvements to enable more successful and flexible patient-specific personalization.

Research into “Black Bone” MRI scanning, software for rapid model production, and how to best address post-surgery complications over the last few years, has enabled huge strides to be taken in anatomical model quality. The communication and management of medical imaging information has also seen improvements, as has communication with patients – after becoming one of the first hospitals in the world to install a J750 to its facilities, the Centre Hospitalier Universitaire de Bordeaux claimed 3D printed models helped patients to understand their surgery up to 50% better than when using a 2D scan.

Last year, Bone 3D, a French manufacturer of personalized medical devices, also installed a Stratasys J750 3D printer to advance its production of patient-specific surgical guides and surgical simulators, and to train future surgeons.

Digital Anatomy software upgrade

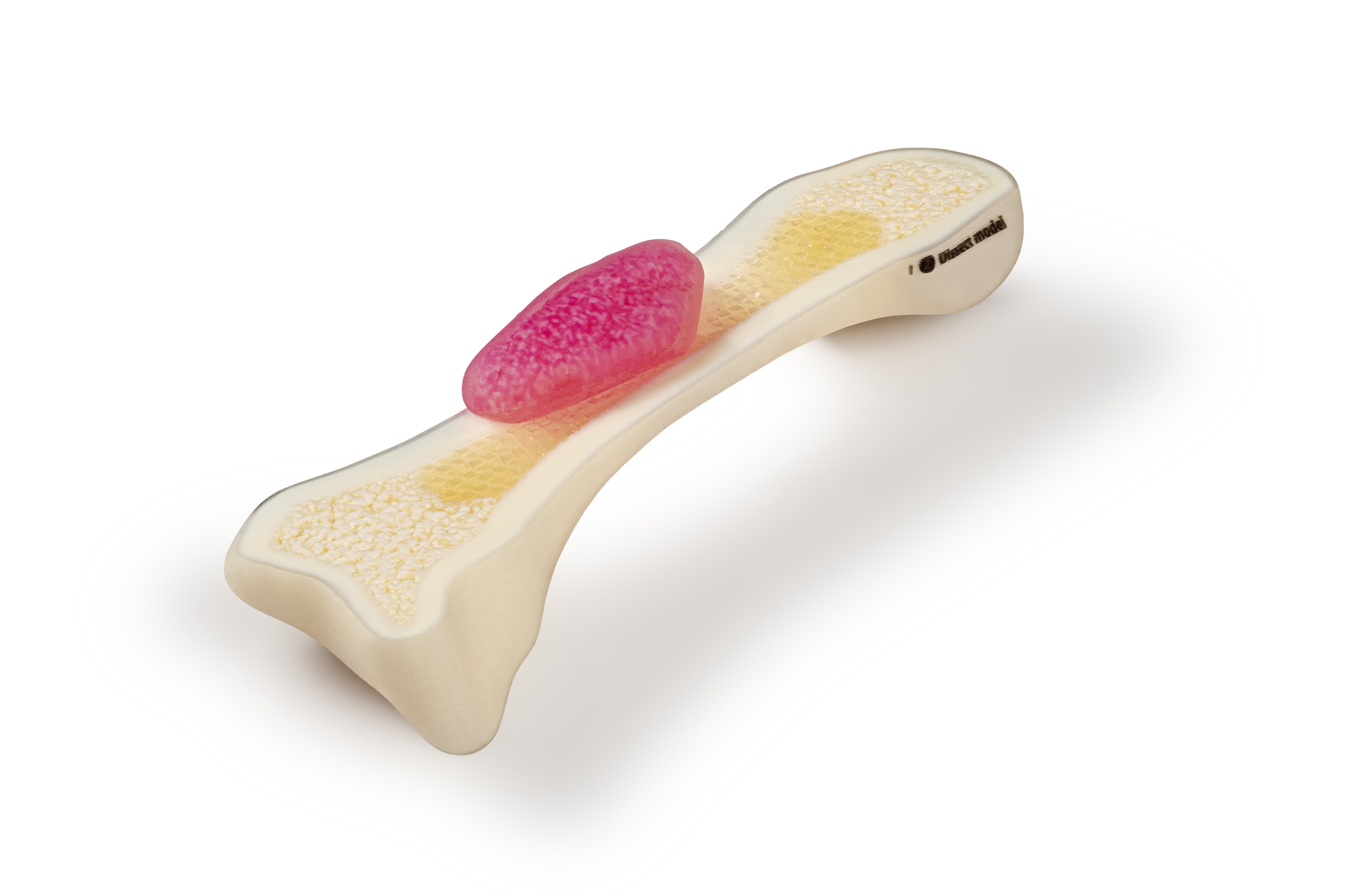

Developed over years of testing with academic medical centers across the globe, more than 100 sophisticated presets have been developed for the J750’s Digital Anatomy software. These presets are designed to replicate real-world conditions, such as the printing of normal or degenerative intervertebral discs, or printing the joints between vertebrae in varying degrees of stiffness. The software enables different combinations of materials to be produced at 3D voxel level in order to obtain the correct biomechanical properties.

A clinical evaluation carried out by researchers at Tel Aviv University investigated how accurately models printed on the Digital Anatomy system replicated screw pull-out force, and concluded the models has a similar haptic response to human cadaver bone. Another study conducted by the Technion Insitute of Technology in Israel demonstrated 3D models of lumbar vertebrae printed on the J750 accurately represented the range of motion detailed by literature on human spines.

So far, Stratasys’ technology has aided healthcare providers in improving surgical preparedness, and has enabled medical device manufacturers to conduct testing and train medical professionals on new devices.

The J750 Digital Anatomy printer

Stratsys’ original J750 3D printer was initially launched in 2016, and over the next three years the system’s capabilities were directed towards the production of anatomical models. This is due in part to the quality and range of colors offered by PolyJet technology, which allows models created with the method to be segmented and color-coded to differentiate complex structures. Last year, the J750 received validation from global color authority Pantone, which led to Stratasys integrating the standards provider’s color management system into the printer’s workflow.

Also beneficial for anatomical models is the J750’s ability to print multiple materials, so different textures can be incorporated into an object for varied functionality. The three materials used by Stratasys in conjunction with its award winning Digital Anatomy system are TissueMatrix, GelMatrix, and BoneMatrix. TissueMatrix is specifically geared towards the replication of heart tissue, while GelMatrix acts as a support material for use inside small cavities of anatomical models. With the clue in its name, BoneMatrix is a strong, flexible material used to replicate bones within an anatomical model.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The Digital Anatomy 3D printer from Stratasys enables physicians to practice inserting screws for orthopedic applications with biomechanical realism similar to a human anatomy. Photo via Business Wire/Stratasys.