Stratasys has unveiled its new Layered Powder Metallurgy (LPM) platform for cost-effective, short-run, industrial-grade 3D printed metal parts.

“Current approaches to 3D printing metal parts leave a lot to be desired – including slow post-processing, painstakingly intricate support removal, and hours of matching and grinding. Combined with the high cost of AM powders, this means each part is expensive, with a total cost of ownership that is too hard to justify,” said Rafie Grinvald, Director of Product Marketing and Management, Stratasys.

“Our new platform is being designed to transform the current metals additive manufacturing landscape – presenting a viable alternative to typical production methods – and helping customers dramatically reduce the costs of creating reliable, consistent production-grade, metal parts for short-run applications.”

Layered Powder Metallurgy

Following a $25 million investment in metal powder producer, LPW Technology, earlier this year, Stratasys announced a forthcoming metal additive manufacturing platform intended “to displace conventional methods for short-run manufacturing,” across the aerospace, automotive, healthcare and consumer sectors.

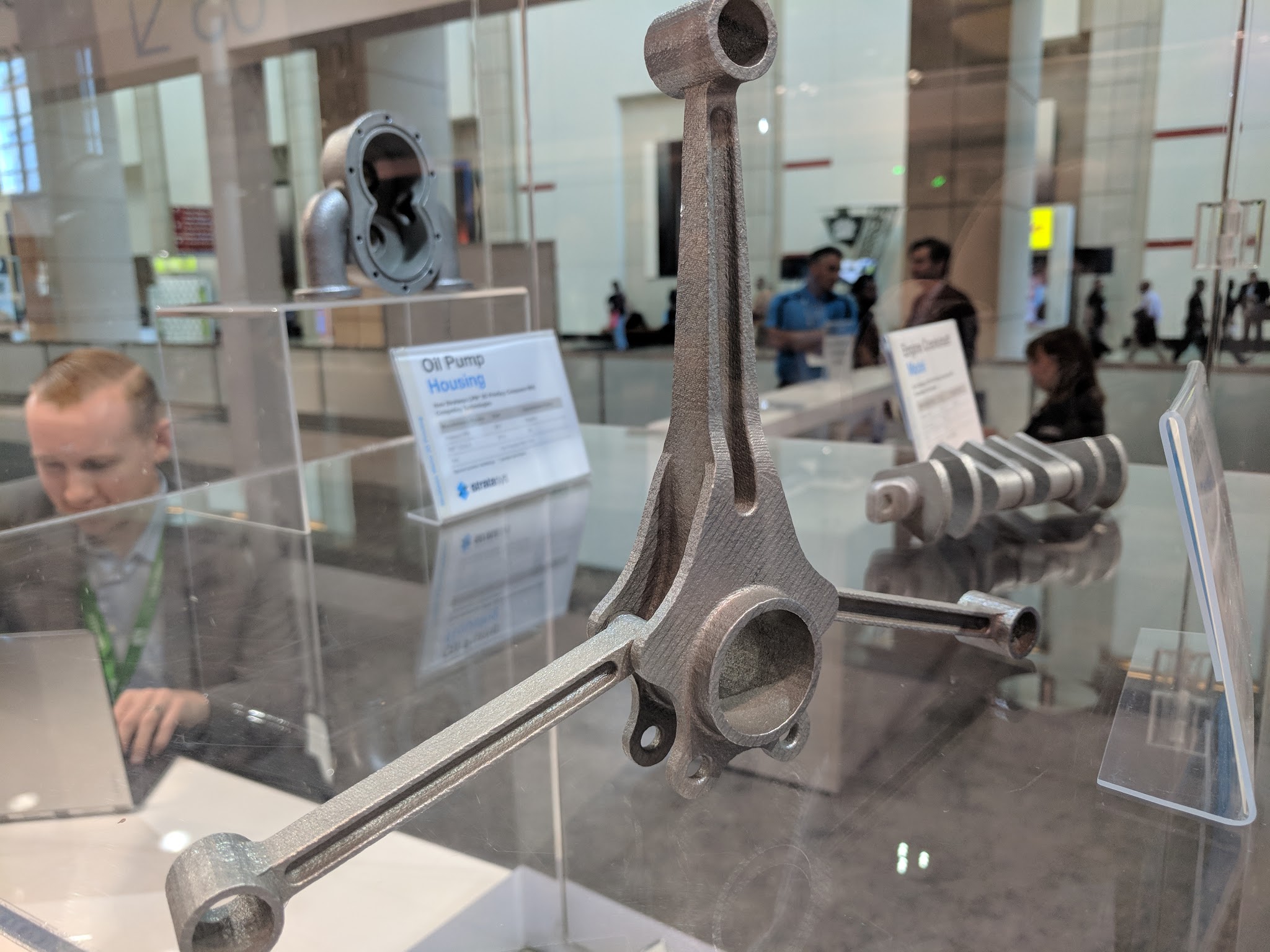

The LPM platform has been under internal development for several years and incorporates Stratasys’ proprietary jetting technology and powder metallurgy, initially for aluminum powders. The 3-step LPM process begins as the powder is dispensed and spread to form a new layer. The layer then goes under a compaction phase to achieve high-density and controllable shrinkage. After, boundaries of proprietary thermal ink are printed onto the thin layer of powder, to define a part’s geometry, thus begins the additive manufacturing process.

This system aims to address the demands of production for pilot-series parts and small-batch manufacturing. Furthermore, due to its compaction phase, the LPM platform manufactures lightweight and complex parts. Stratasys is currently in closed-loop feedback discussions with OEMs and Tier-1s on the new metals platform.

Further product specifications and launch timelines will be made available in the near future. Formnext visitors can find Stratasys in Hall 3.1, Stand G40.

Stay updated with the latest 3D printing from Formnext by subscribing to our 3D printing newsletter. You can also follow us on Twitter and Facebook.

Visit our 3D Printing Jobs to start a new career in 3D printing.

Featured image shows 3D printed metal parts produced using the LPM system. Clip via Stratasys.