Leading 3D printer OEM Stratasys has launched a new PolyJet system: the J850. Replacing the company’s award winning J750 3D printer, launched 2016, the machine is reportedly capable at 3D printing at twice the speed and at a “significantly lower cost.”

Emphasizing the full color capabilities the J-series is known for, the J850 is marketed by Stratasys as a 3D printer “designed for designers,” coming into its stride in product development applications for the toy industry, consumer goods, consumer electronics and automotive.

Ahead of today’s launch, 3D Printing Industry spoke to Tomer Gallimidi, Senior Product Manager at Stratasys, to learn more about the J850 and what this means for its predecessor.

Inside the Stratasys J850 – new materials, more seamless design

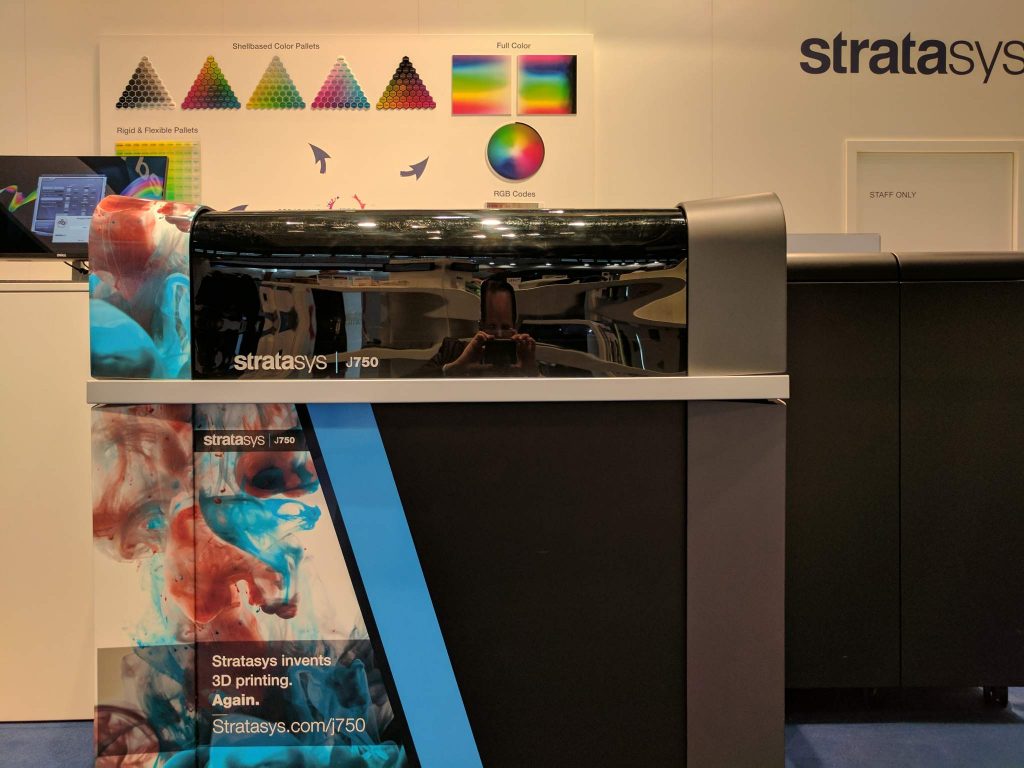

Stratasys PolyJet technology is one of the few processes on the market that is capable of seamlessly providing multi-material 3D printing capabilities. In the J750, this was realized by the ability to 3D print with up to 5 materials in a single part, i.e. cyan, magenta, yellow, black and white.

With the J850, users now not only have access to the full color spectrum in their 3D printers (over 500,000 shades to be exact) they can make use of color in combination with both clear and flexible materials. As a direct upgrade to the J750, the J850 is also backed by the Pantone Validation the company received for its J-series earlier this year. “When you are using the standard language like Pantone,” Gallimidi comments, “[design communication] is more intuitive […] your decision making is becoming much easier and more efficient because it allows you to choose the exact pattern on the screen that you will get in your hand,” not only in the 3D printed model, but also the end product.

By bringing these capabilities to the J850, Stratasys is hoping to give designers a way of making prototypes that are as close in appearance and texture to the end product as possible. Speaking of the core consumer areas where the the company is pitching its latest system, Gallimidi says, “The design of those products are critical in the decision making the customer is doing, and if they will buy the product or not.”

Another way Stratasys is appealing to the rapid product development lifecycle, is a “High Speed Print Mode” on the J850. As expected, Gallimidi confirms that working in this mode does come at a compromise to the overall quality of the printed object, however the difference is not significant. DraftGrey resin, one of the new materials launched by Stratasys alongside the J850, is particularly suited to take advantage of the machine’s high printing speeds. Again playing into the designers hands, DraftGrey is for use in the early stages of a product’s development cycle, allowing users to physically draft the shape of a product. The neutral color of the resin serves as a blank canvas as an idea comes to fruition.

VeroUltraClear is the other material launched alongside the J850. Sample objects made using of this material have impressive optical qualities, though Gallimidi could give us little information about the post-processing required to achieve such an effect.

In addition to enhanced material capabilities, Stratasys is promising customers a full “end-to-end” solution for product design in the J850. Part of this has included working with the software used by designers in order to provide a seamless workflow from model to design to 3D print. As such, Stratasys GrabCAD Print software can reportedly be used to 3D print “directly from a user’s favorite professional CAD format.” This includes compatibility with SOLIDWORKS and CATIA.

Padwa Design, a consumer product design studio based in Israel, is one of the first customers of the J850. Gallimidi also suggested that the machine already has at least one customer in Germany.

“With this solution,” Padwa Design founder Alex Padwa, comments, “there’s no need to add or switch technologies throughout the design process.”

Full technical specifications and availability of the Stratasys J850

Other than added material capabilities and the improved print speeds, technical specifications of the J850 remain the same as the J750. As such, the company is offering J850 capabilities as an upgrade to existing customers of the J750 which, Gallimidi disclosed, is an installed base of 100s of systems.

The J750 will continue to exist at Stratasys as the J750 Digital Anatomy 3D printer launched by the company earlier this month.

Technical specifications for the J850 (and former J750) can be seen below.

Build size: 490 x 390 x 200 mm (19.3 x 15.35 x 7.9 in.)

Layer Thickness: Horizontal build layers down to 14 microns (0.00055 in.)

Workstation Compatibility: Windows 7 and 8.1

Network Connectivity: LAN – TCP/IP

System Size and Weight: 1400 x 1260 x 1100 mm (55.1 x 49.6 x 43.4 in.); 430 kg (948 lbs)

Material Cabinet: 670 x 1,170 x 640 mm (26.4 x 46.1 x 25.2 in.); 152 kg (335 lbs)

Operating Conditions: Temperature 18 – 25 °C (64 – 77 °F); relative humidity 30-70% (non-condensing)

Power Requirements: 100–120 VAC, 50–60 Hz, 13.5 A, 1 phase

220–240 VAC, 50–60 Hz, 7 A, 1 phase

Regulatory Compliance: CE, FCC, EAC

Pricing for the J850 is available from Stratasys on request. The company is currently accepting orders for the system, which are expected to be ship within Q4 2019.

For all of the latest 3D printer releases subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook. Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows a clear and colorful perfume bottle sample made on the new Stratasys J850. Photo via Stratasys