German ceramic 3D printing company StoneFlower3D has presented a print head for processing clay, concrete and pastes in 3D printing. A durable and corrosion-resistant extruder, the print head is intended for the 3D printing of clay and pastes in academic research, material science, and professional environments.

Named Print head 3.0, the new device has been CNC-milled from stainless steel 1.4301 304/V2A and AL6061-T6 alloy to ensure its durability. Additionally, the company claims that it features an optimized design that maintains uniform flow of the material, preventing leaks and jamming. Print head 3.0 is available for purchase on the StoneFlower3D website for 240 € ($266.61).

History of StoneFlower3D

Founded by Anatoly Berezkin in 2017, StoneFlower3D is a company specializing in paste deposition 3D printing technology using ceramics. Berezkin initially became familiar with 3D printing in 2013 when he operated as a researcher at the Max-Planck Institute in Düsseldorf. Focusing on the 3D printing of resins from viscous components, Berezkin has released a couple of research papers about the principles of this process with Covestro, a German manufacturer of high-performance polymers.

After gaining experience in the development of automated research equipment, building CNC routers and 3D printers during his time at Technical University of Munich (TUM), Berezkin developed the Ceramic 3D Printing KIT, and launched StoneFlower3D and a Kickstarter campaign around the technology. The Ceramic 3D Printing KIT includes a print head, ram extruder, and control unit. It can be installed on a number of desktop FDM printers using the provided pipes, connecting wires and adapters, allowing them to print in clay or porcelain.

As well as the KIT, StoneFlower3D has also developed its own desktop 3D printer. Equipped with a 480 x 480 x 500 mm print volume, the StoneFlower 3D printer is capable of printing in clay, porcelain, concrete, paste and paints. Customers also have the choice of a dual extrusion version of the 3D printer upon request. The StoneFlower 3D printer is priced at 3499 € ($3,859.94).

Many ceramic 3D printer manufacturers, like Admatec, 3DCeram and XJet, develop systems geared towards industrial purposes, as opposed to desktop-level 3D printers. However, various companies, like StoneFlower3D and Italian 3D printer manufacturer WASP, have also developed more accessible, cheaper 3D printers for processing ceramics. For example, WASP provides its Delta WASP 40100 ceramic 3D printer, which is capable of processing clay, and available for purchase at 6900 € ($7,609.98). It has been used by sculptor Andrea Salvatori to produce an eye-catching collection of 3D printed ikebana vases.

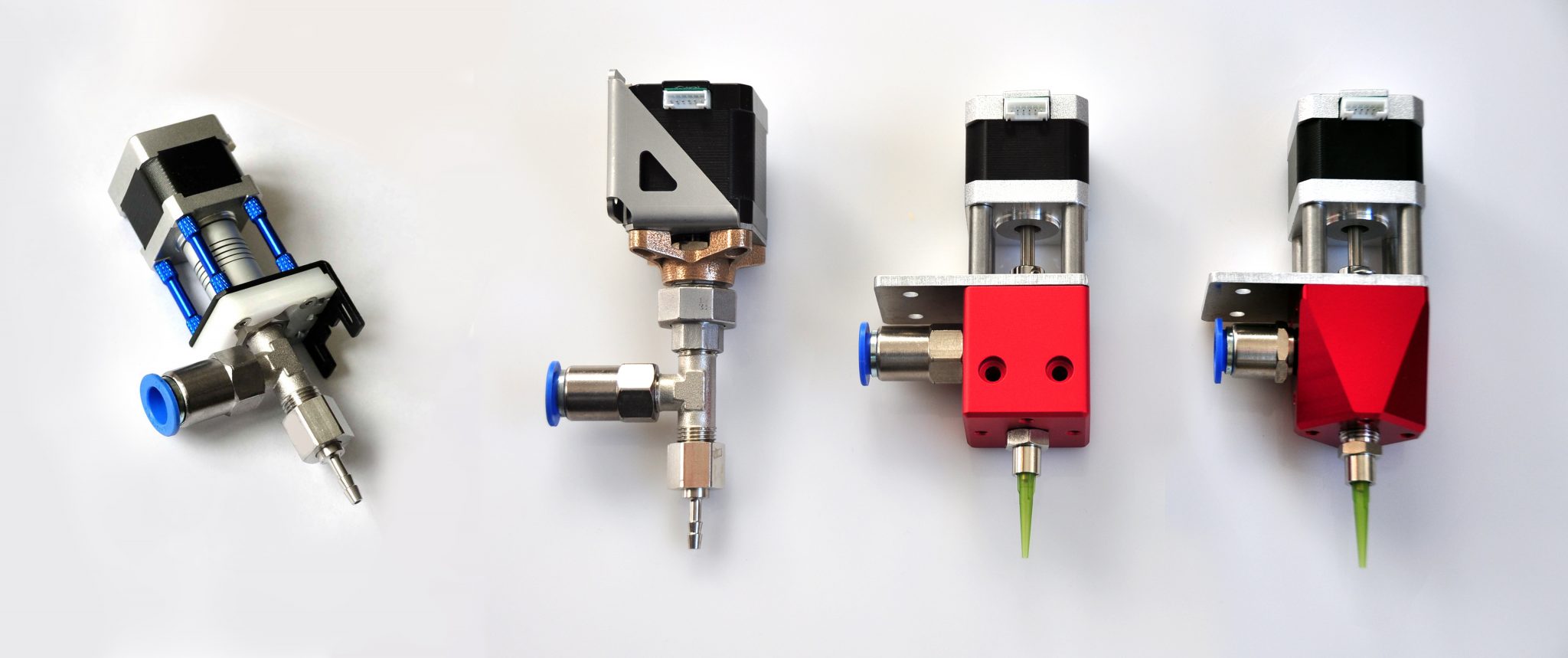

The upgraded Print head 3.0

StoneFlower3D’s new and upgraded Print head 3.0 replaces the 2.0 version used in the Ceramic 3D Printing KIT. Seeking to improve the performance of the print head, StoneFlower3D performed a number of tests on different prototypes of the auger screw on the extruder, which were 3D printed. They were tested with real clay to refine the shape of the screw, improve stability of the flow, and reduce wear, and hydraulic resistance of the print head. From the tests, the company concluded that the auger screw design with two concave flutes performed the best. This design was then CNC-milled from stainless steel for the final part.

As the Print head 3.0 is included in the Ceramic 3D Printing KIT, it has been designed to be compatible with a variety of FDM and clay 3D printers, including the StoneFlower 3D printer. The Nema17 stepper motor on the print head can be connected to the standard mainboards on an FDM 3D printer in place of the extruder. The stator’s inlets and outlets are also compatible with standard NPT threads of pipe fittings, hose connectors and nozzles.

Additionally, Print head 3.0 has been designed with a number of mounting holes, to ensure compatible installation and upgrades on different FDM systems. All parts on the print head that comes into contact with the extruding material can also be dismounted to facilitate easy maintenance. Components susceptible to wear, including the bronze bearing and seal, are non-proprietary, and can therefore be easily replaced by the user.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The Print head 3.0. Photo via StoneFlower3D.