3D printed drugs have, by some, been heralded as the future of pharmaceuticals. But, what if, instead of limiting the drugs by their ability to be 3D printed, we could use 3D printers to fundamentally changed the way they are made?

A new study from the University of Glasgow has demonstrated how chemical synthesis is possible with desktop 3D printers.

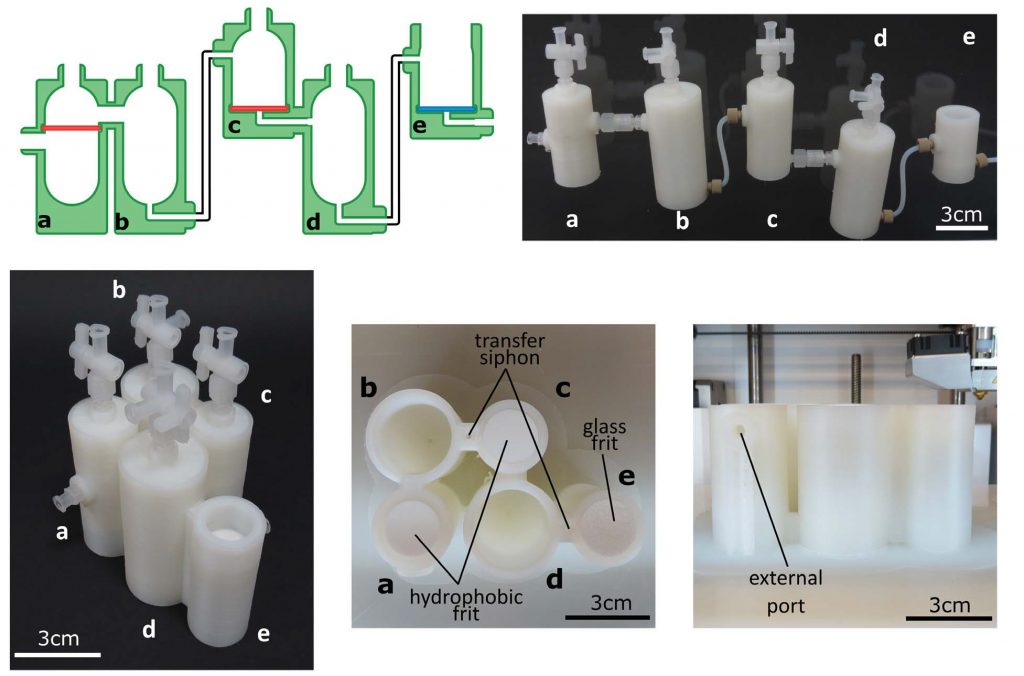

The idea, led by Professor Leroy “Lee” Cronin at Glasgow’s School for Chemistry, is to replace expensive glassware, such a flasks and tubes, with a pick and mix set of modular, 3D printed plastic vessels.

Delivered as a set of digital .stl files, the ‘reactionware’ kit could one day become the Spotify of drugs, allowing users to download, and 3D print their own chemical modules on demand.

The “Spotify of drugs” in action. Example setup of Cronin et al. 3D printed modular reactionware and the chemical synthesis process. Clip via Science, supplementary materials

Paving the way for the future of medicine

Though new drug compounds are made and classified all the time, the first challenge with bringing them to market is launching a suitable production facility. As each drug is unique in composition, it also requires a specific manufacturing setup.

To give an example, Cronin et al. choose to make baclofen, a medication sold as a muscle relaxant. In order to make baclofen, the team needs 12 interlinking units, each with a customized outlet, interior or stirrer.

Input and output tubes are added in a CAD program. But, for features needed to produce a specific or electrochemical reaction, prints are simply paused so an inner coating or metal rod/stirrer can be added.

Each of the models in the experimental section are made using the lab’s own Ultimaker 3D printers.

“The chemist now becomes a digital designer,” explains Cronin, “The chemist doesn’t have to get their hands dirty.”

Up against the FDA

Baclofen muscle relaxant is used simply as a proof of concept in the study. The real value of the process will be in ability to make the hard-to-get compounds that have so far stayed in the lab.

Cronin and the team are currently working to develop models for these rare and important compounds that could dramatically slash a $1 million price tag.

The biggest barrier now will be receiving certification for the system from appropriate medical bodies, such as the U.S. Food and Drug Administration (FDA) and the UK’s Medicines and Healthcare Regulatory Authority (MHRA). So far though, Cronin is optimistic “I thought the FDA would take me apart, but they said “We love this because you’re making standard modules for doing chemistry”.”

“Digitization of multistep organic synthesis in reactionware for on-demand pharmaceuticals” is published online in Science journal it is co-authored by Philip J. Kitson, Guillaume Marie, Jean-Patrick Francoia, Sergey S. Zalesskiy, Ralph C. Sigerson, Jennifer S. Mathieson and Leroy Cronin.

Never miss out an another story – subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections for best medical application and more here.

Featured image shows graphic of the 3D printed reactionware process. Image via Science, supplementary materials