As far as powder-based technologies are concerned, I can currently count eight commercial, direct metal 3D printer manufactures in the world. One is in the UK, one is in the US, one is in Sweden, four are in Germany, and one is in Italy. Three of these are part of larger groups that are leaders in subtractive technologies in their fields. Sisma, the one Italian SLM 3D printer manufacturer, is one of these.

Based in the Vicenza region, one of Italy’s three centres for its jewellery industry, Sisma is also the first company to perfect additive manufacturing of precious metals. Gold and other precious metal alloys were among the first powder materials to be implemented in the company’s MySint100 3D printer, launched in 2014. Invited by Lisa Marta Micheletto, Sisma’s Project Leader for Additive Manufacturing, I have the opportunity to visit the company’s office and 3D printer and laser-related products manufacturing facility. This specific arm of Sisma is located in Piovene Rocchette, a small town in the Veneto Region and Italy’s highly productive North East. The company is already an established international enterprise, with commercial offices worldwide, and it has recently formed a joint venture specifically centered on additive manufacturing with the German Group Trumpf.

The building I visit is bright, spacious, and modern. Both outside and inside. Engineers, researchers, and testers work around a very large open space, with several dedicated rooms connected to it. Sisma specializes in jewelery machines and laser systems and the whole facility almost looks like a shiny jewel itself. We sit around a table in the open space, surrounded by immaculate-looking CNCs, laser cutters, and a MySint 3D printer. The other printers, as I will discover later on, are just behind a door, in the huge assembly plant and QA testing rooms.

“As in all sectors of manufacturing, we find that designers still need to fully understand how to exploit the manufacturing capabilities of a direct metal 3D printer in order to create unique products that offer new possibilities in terms of shape and performance,” Lisa says. “If you want to use a 3D printer to make the same products you are already making, just a little faster, then you are only exploiting a tiny part of the machine’s capabilities. You need to evaluate shape, supports, speed, polishing requirements… Discovering and communicating what these possibilities are to designers and engineers is the hardest part of our job.” One way that Sisma AM’s division goes about exploring possibilities is by partnering with Nuovi Gioielli, a local jewel manufacturer that has brought a MySint in-house and has been experimenting with it, coming up with some of the amazing products in the images you see here.

Other than that, the MySint100s are doing quite well. The AM division is growing rapidly, along with demand for the 3D printers, especially in the dental sector and in what Sisma calls its “Jewellery” division (which includes fashion applications). Fashion designers use the MySint to make items that they are going to use only once, on the runaway. These are the first and main adopters at this point; it is more or less the equivalent of Formula One racing for the automotive industry.

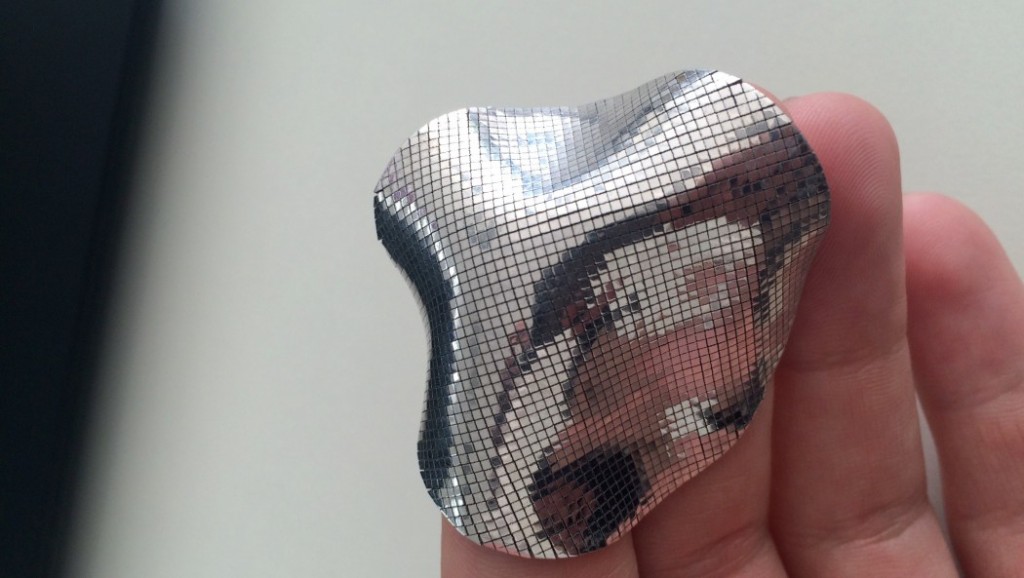

Jewelry is also one of the fastest growing AM markets in general and the advantages of direct metal printing over lost wax casting are starting to become clearer, both in terms of precision and geometrical possibilities. With SLM there are no preset geometrical limitations, and it also means you can make products like this, straight out of the 3D printer.

For example, the patented arm to deposit the powder layers, which drastically reduces the time it takes to return to the initial position after each layer deposition. Or the fact that the MySint100 offers the possibility to accurately calculate the amount of powder necessary and thus use only that amount by modifying the size of the powder receptacle. This and several other functions of the manufacturing process can be easily regulated and controlled through the on-board touch screen monitor.

The MySint 3D printers are being adopted in other areas as well, with dental being the fastest growing segment. Dental labs are most receptive to AM technology and the advantages are clearer: fast manufacturing and better quality; however, Lisa explained, it is still mostly the larger dental labs that can bring a metal 3D printer in house. Another field where the technology is adopted is engineering and industrial manufacturing, but the size of the Sisma machine, with a cylindrical workspace measuring 100 (diameter) x 100 (height) mm means that its applications are still limited. Other limitations include the fact that certain highly complex structures would require too much time to polish, thus reducing the time advantage. But there is no way to use any other process to make something like this – a “kinematic metal fabric” – in a single run.

Currently, the three different MySint100 versions (Fashion, Dental, and Industry) can work with cobalt-chrome, stainless steel, as well as bronze, gold and several precious metal alloys. Titanium and other reactive materials are currently been developed through an add-on module. They will likely be announced at the upcoming trade shows (Sisma is going to exhibit both at Euromold and Formnext). These are likely not going to be the only news coming from the Italian manufacturer in the near future, as the Sisma-Trumpf joint venture further materializes and designers start to become more aware of waht can be achieved through direct metal AM. The future looks shiny and bright.