Rainier Square Tower, a new 58-story building set to grace Seattle’s skyline in 2020, is to include 140 3D printed brackets. Made by Californian digital manufacturing service provider 3Diligent, the individual nodes used in the building’s cladding assembly have been produced to achieve the tower’s unusual quarter-pipe-like appearance.

A redesign of the original Rainier Tower designed by Seattle-born architect Minoru Yamasaki, the new landmark building will feature a staggered series of floors, echoing features of the original and giving panoramic views. According to Wright Runstad & Company, the firm managing the $570 million Rainier development, “We are designing more than just a new skyscraper. We are building a place, right in the center of Seattle. All the buildings and open spaces in this block are part of the greater whole.”As in the words of the late Yamasaki:

“A building must be like a human being. It must have a wholeness about it, something that is very important.”

The small, 3D printed parts, of the whole

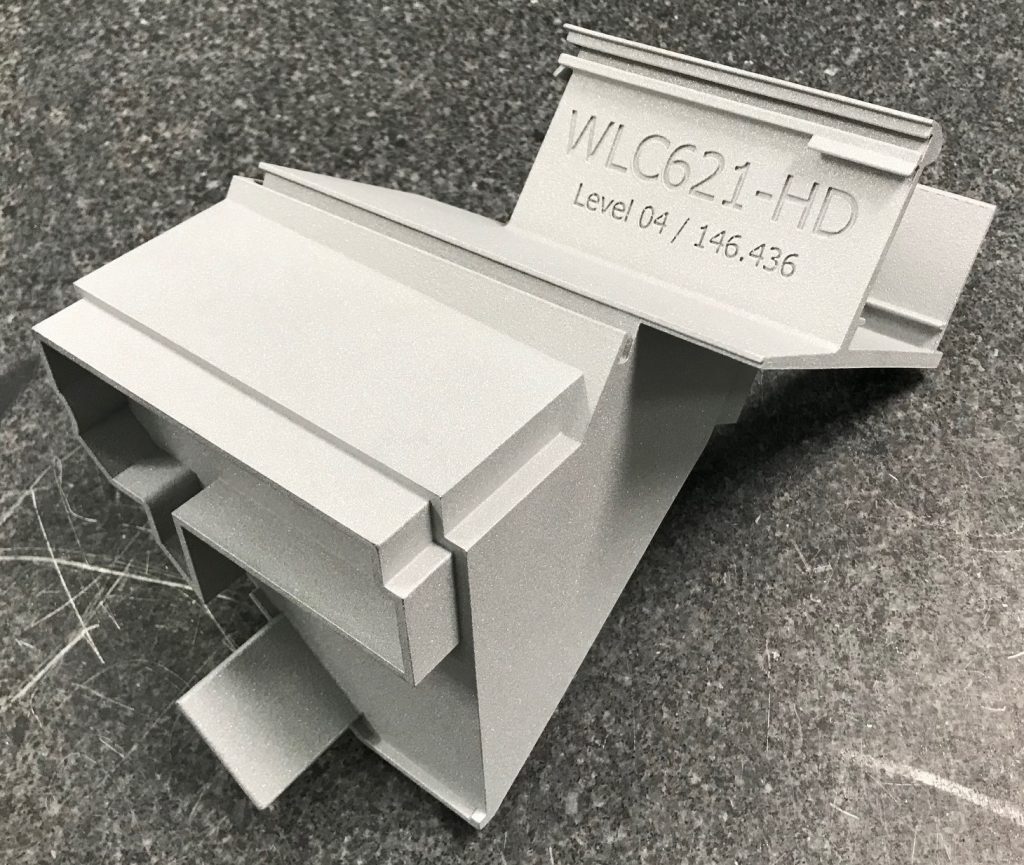

Construction cladding specialist Walters & Wolf is contributing to the external features of the new tower at Rainier Square. Due to the way the lower floors of the tower slope, the specifications of the cladding for each floor is entirely unique. The company’s approach to the design therefore is to assemble each floor’s cladding from a series of complex v-shaped nodes.

Working with 3Diligent, Walters & Wolf initially received node prototypes made using investment casting and additive manufacturing. These parts were sent for independent testing at a lab in Fresno, California. Here they were specifically tested for cracking, their adhesion to silicone, and ability to remain water and air-tight – as the nodes are not required to bear any large structural lodes when installed.

3D printing became the manufacturing method of choice following these tests. “It was great that 3Diligent gave us both investment casting and 3D Printing options so that we could choose between them,” explains Walters & Wolf Curtain Wall Designer Jon Ishee.

“We prototyped in both technologies and ultimately picked 3D printing because of the dimensional accuracy and structural reliability it gave us.”

Coming 2020-2021

Following prototyping and verification, 3Diligent then 3D printed 140 unique construction nodes for the Rainier project, each with a different dimension ranging up to almost 1 cubic foot in size.

Speaking of the project Tony Parker, Project Executive at Walters & Wolf, comments, “From an operations standpoint, we were impressed with 3Diligent’s consistency in delivery of highly accurate and complex parts in a timely fashion that was in sync with the production schedule we established early on.”

“At the end of the day, 3Diligent upheld their end of the bargain – they simply did what they said they would do.”

Other construction projects turning to 3D printing as fabrication solution include David Wolfertstetter Architektur’s renovation of the Deutsches Museum in Munich, and the city of Dubai.

When completed, the Rainier Square Tower will be the second tallest building in Seattle, shadowed only by the 76-story Columbia Center. It is a mixed-use building offering retail, dining, residential, office, hotel and parking spaces to businesses and individuals in the Space-needle city.

Set for partial opening in 2020, the block’s entire office space (722,000-square-feet) was to become a new Amazon headquarters. Due to high taxes imposed upon such large businesses by the Seattle council and increased pressure from the local community, the electronic super-shop has since motioned to sublease this space to other companies. Full functions of the tower, including residential space, are scheduled to be habitable by the end of 2021.

For more of the latest 3D printed architecture news, subscribe to our newsletter, like us on Facebook and follow Twitter. Looking for a job in the industry? Visit our 3D Printing Jobs board.

Featured image shows the iconic, curved design of the new Rainier Square Tower opening 2020. NBBJ rendering by Atchain.