The Dutch Ministry of Infrastructure, Rijkswaterstaat, has selected 10 participants for a Small Business Innovation Research (SBIR) program to present new concepts for a total concept circular viaduct.

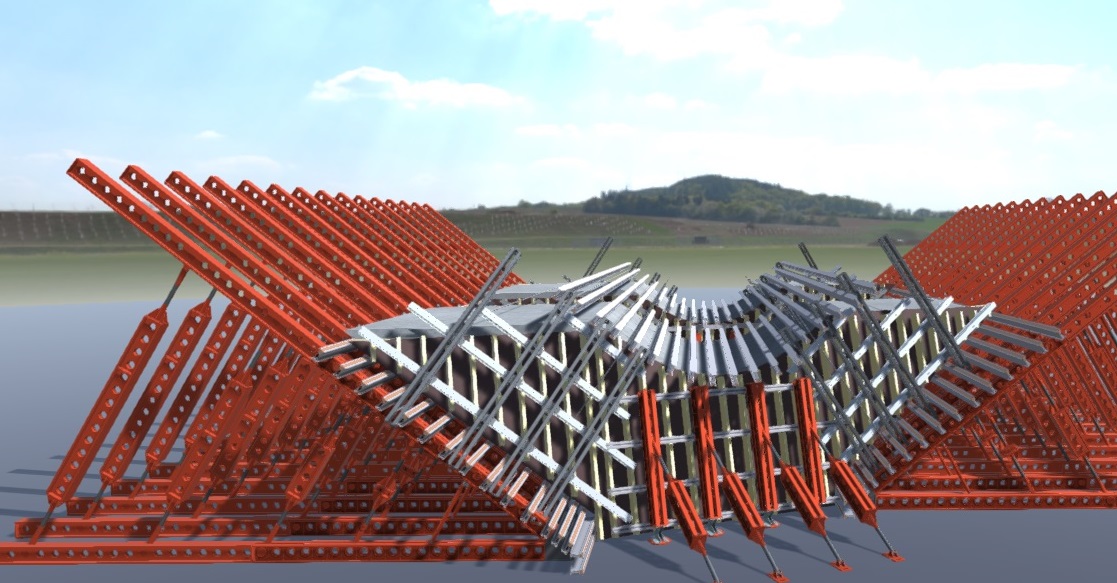

Part of the HONEYCOMB project, the SBIR tender aims to bring circular viaducts to the market more quickly through technologies such as automated 3D printing.

The 10 entries which will continue to the feasibility stage are: Arcadis Nederland BV, Consortium Vici vof, Heijmans Infra BV, Max Bogl Nederland BV, Mobilis BV, NV BESIX SA, Nebest BV, Royal Haskoning DHV, Studio RAP and Witteveen + Bos Raadgevende Ingenieurs BV.

“I am very enthusiastic about the amount and diversity of registrations. That says a lot about the current dynamics in the market. The parties involved all want to make a difference,” said Robert de Roos, Top Advisor Technology, Rijkswaterstaat.

Aims of the SBIR call

According to Rijkswaterstaat, there is currently an insufficient supply of circular viaducts. This is due to the requirement for further technical development of existing concepts, or these concepts haven’t yet been adequately tested and validated.

Rijkswaterstaat is therefore seeking alternative innovations in this area, specifically those which will provide a lower environmental impact over the viaduct’s lifespan. Submissions must adhere to at least one of the authority’s directions; the concept must either be modular and detachable, involve the highest possible reuse of existing parts or materials, or be based on renewable materials.

The proposed innovations must be either a total concept, or if it is a partial solution, must be indicative of how it would fit into a total viaduct concept.

“There was a great diversity of solution directions between the proposals,” said Professor Mark Huijbregts, Professor of Integrated Environmental Analysis at Radboud University Nijmegen and part of the SBIR assessment committee. “There were proposals that primarily focus on the use of wood, composite or circular concrete. While other proposals focus on reducing material use by tinkering with the viaduct design itself.”

Rijkswaterstaat aims for the Netherlands to be fully climate-neutral and circular by 2030, and part of this will be the construction, renovation, and replacement of viaducts and bridges throughout the country.

SBIR timeline and budget

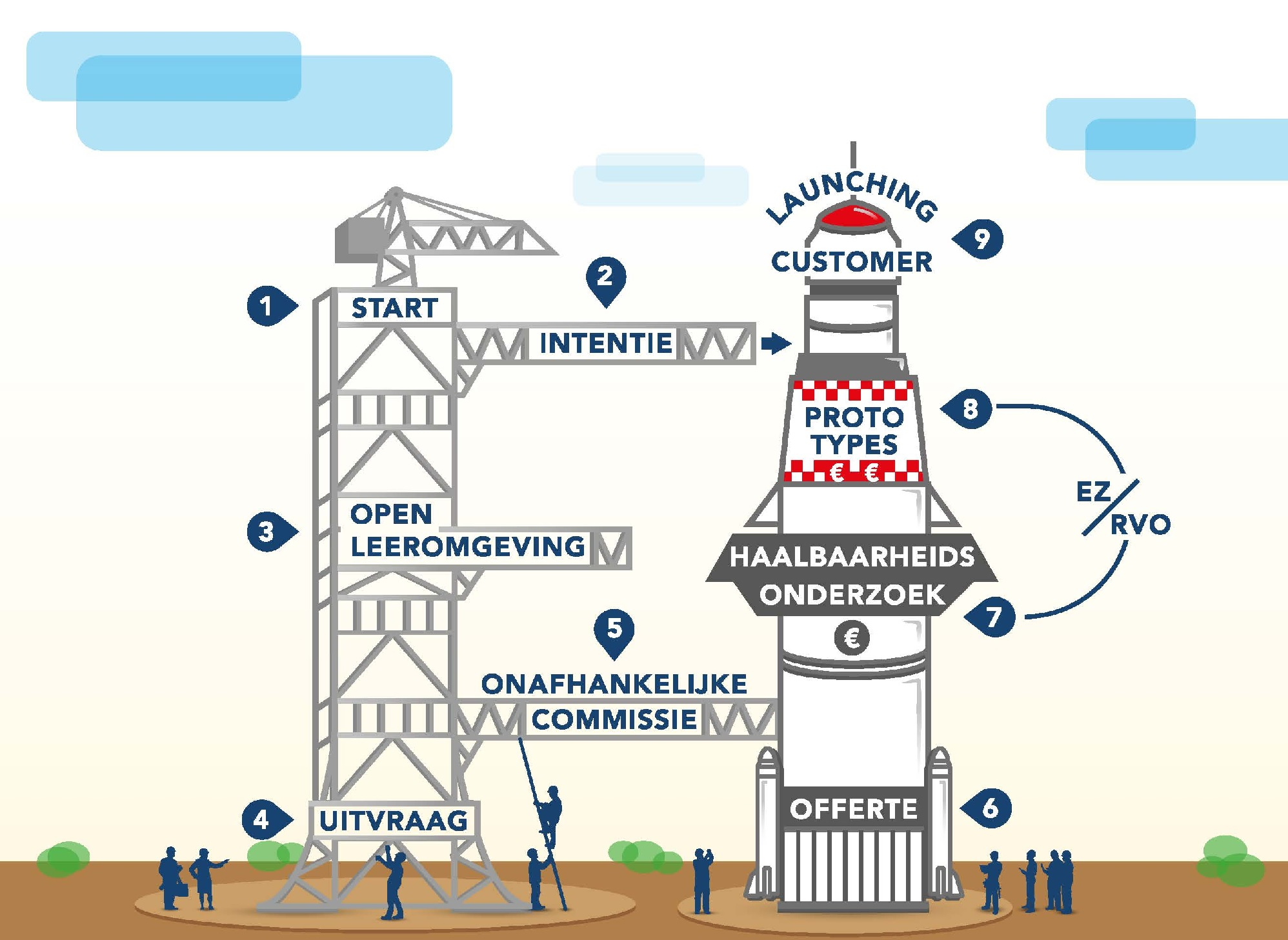

The SBIR call for entries is now closed, and 10 submissions have been selected for the phase one feasibility study. The best ideas from the study will be given a follow-up assignment to produce a prototype during phase two of the SBIR, due to be completed by mid-2022.

The SBIR has a total available budget of €5.4 million. A budget of €900,000 is available for the first phase of the program, with a maximum of €90,000 available to each participant. A €4.5 million budget will be designated for phase two with each project eligible to receive up to €1.5 million in funding.

On October 7, the 10 feasibility study entrants will be presented with the plans for the rest of the SBIR in a kick-off meeting in Utrecht.

Additive manufacturing in infrastructure

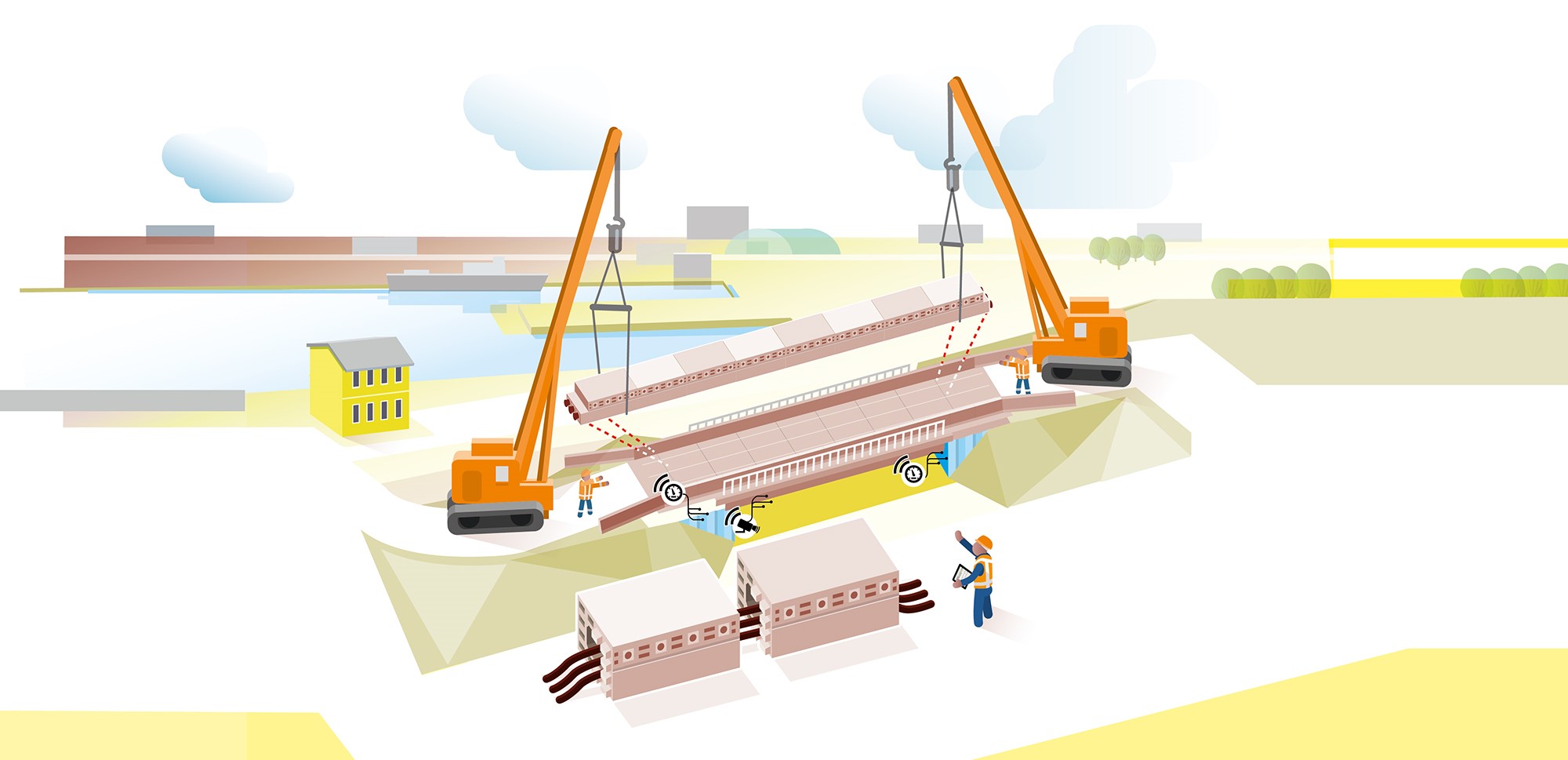

The architectural applications for 3D printing have widened significantly in recent years, with several bridge and viaduct projects completed around the globe. Typically, a viaduct is a long bridge-like structure consisting of a number of short spans, which carries a road or railway across a valley or other low ground, while a bridge is constructed over water.

Last year, VolkerFitzpatrick, RMD Kwikform, and Sword Construction UK, constructed a new 1.7km viaduct with ‘V’ shaped piers in Cambridge, using 3D printed prototypes and a 3D visualization tool. The viaduct bypass was constructed to ease congestion in and around the small city of Ely.

Elsewhere, Shanghai Mechanized Construction Group Co (SMCC), a Chinese construction company, and Polymaker, a 3D printing filament manufacturer, collaborated to 3D print a pedestrian bridge in Shanghai’s Taopu Smart City, Putuo District. The bridge, which was printed using Acrylonitrile Styrene Acrylate (ASA), a robust plastic, spans 15.25 meters long and 3.8 meters wide.

Most recently, global nutritional science firm DSM partnered with Netherlands-based engineering consultancy firm Royal HaskoningDHV and the City of Rotterdam, to 3D print a footbridge from recyclable source materials. Set to be opened by the end of 2020, the bridge will be the first to utilize fiber-reinforced thermoplastics (FRPs) for this purpose.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the SBIR process for the development of circular viaducts. Image via Rijkswaterstaat.