Digital services company Ricoh has partnered with industrial manufacturing firm Siemens to optimize aluminum binder jetting (BJT) technology for industrial-scale mass production.

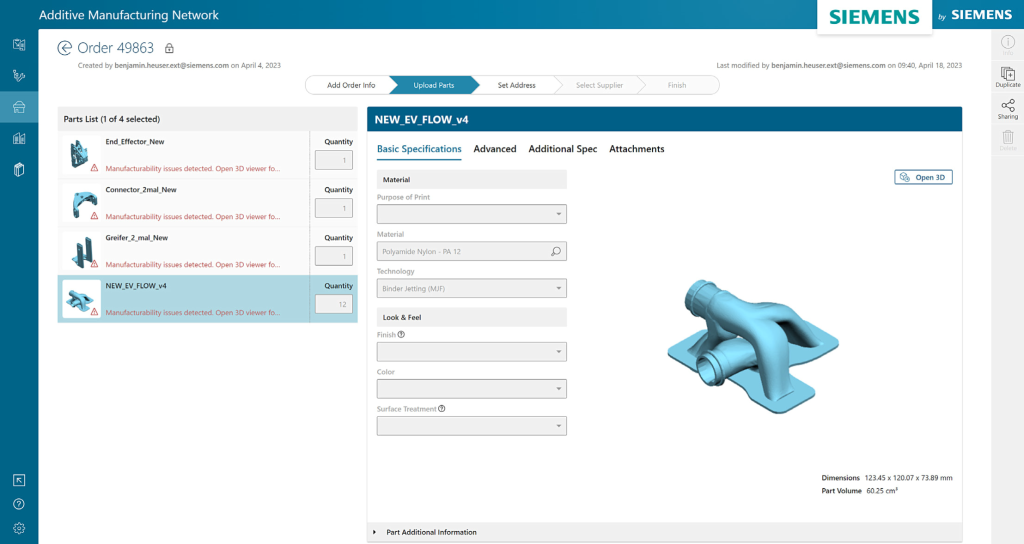

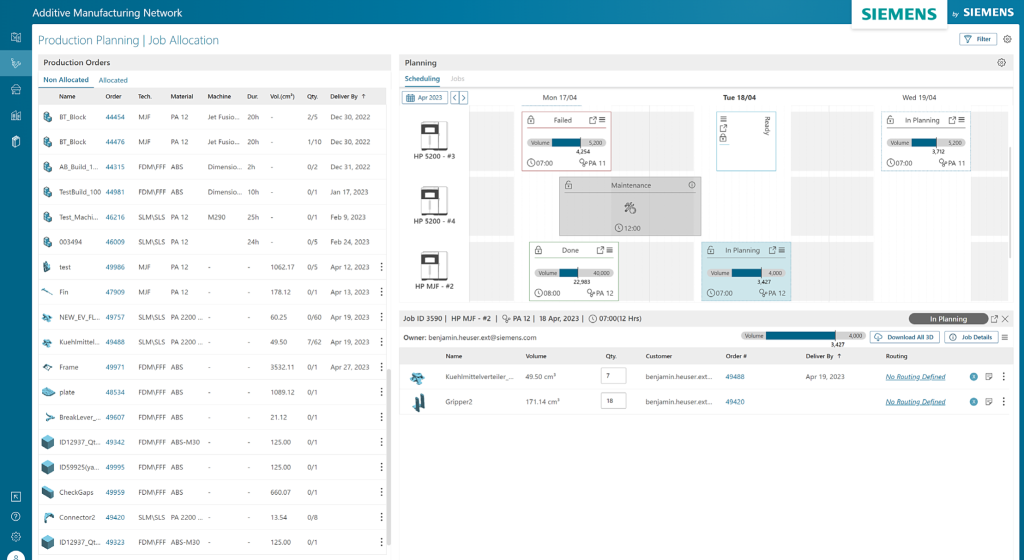

Ricoh is utilizing Siemens’ Additive Manufacturing Network digital platform to increase the efficiency of its BJT process, scaling the technology to meet industrial production demands.

Ricoh aims to build a digital platform that optimizes the internal processes and manufacturing of its aluminum binder jetting technology. This will span from 3D print job preparation to the delivery of finished components. The company hopes to “digitally transform” its process service offering to meet a growing range of industrial additive manufacturing customers, especially within the electric vehicle (EV) industry.

Ricoh has also integrated Siemens’ Brownfield Connectivity, and is actively collecting and storing information on the processes necessary for production control and quality stabilization.

“The production of aluminum parts is a holy grail for the additive industry and we’re delighted that Ricoh has chosen Siemens’ Additive Manufacturing Network capabilities from the Siemens Xcelerator portfolio of industry software to help them commercialize a much sought-after process,” commented Zvi Feuer, Senior Vice President, Digital Manufacturing Software, Siemens Digital Industries Software. “Our collaboration with Ricoh will apply its expertise in additive manufacturing with our knowledge and experience in delivering additive-specific operations management technology across a wide spectrum of industries – from order capture, production planning, and manufacturing to part delivery transaction closure”

“Together, Siemens and Ricoh are working to deliver repeatability and consistency at the scale needed to truly take advantage of using robust and repeatable aluminum additively manufactured parts in the commercial world,” added Feuer

Both Ricoh and Siemens are hoping for an early commercialization of this new binder jet offering.

Scaling Ricoh’s binder jetting technology

Ricoh’s proprietary binder jetting technology leverages the company’s inkjet printing expertise to manufacture metal parts with complex geometries that would not be possible through conventional manufacturing methods.

During the BJT process, aluminum-alloy powder is dispersed over the build area. This powder is then solidified into a predetermined shape by a specially formulated binder. This process is repeated layer-by-layer, until the final part has been produced. The completed “green part” is then sintered in a furnace, creating a dense end-use component.

According to Ricoh, the company’s binder jetting technology offers several advantages for the production of aluminum parts. Notably, this process is said to enable weight reductions and improved heat exchange performance, by facilitating the production of shapes not possible with conventional processing technologies. Binder jetting also reportedly offers significant time and material savings, thanks to its high productivity and ability to recycle material.

Through this new partnership with Siemens, Ricoh hopes to further its goal of realizing “a zero-carbon society.” The Japan-based company aims to achieve zero GHG emissions throughout the entire value chain, allowing the mass-production of highly energy-efficient products using its metal 3D printers.

“Ricoh will enable our customers to manufacture innovative aluminum components that have never been produced before by any process and will work with them to realize new customer value in the area of electrification of EVs and other forms of mobility,” explained Tokutaro Fukushima, General Manager of Ricoh’s Additive Manufacturing Business Center.

“By combining Siemens’ powerful solutions and knowledge with Ricoh’s aluminum BJT, we will be able to provide our customers with highly reliable and practical systems for mass production applications. We hope to promote electrification together with our customers and contribute to solving social issues such as realizing a zero-carbon society.”

3D printing for mass production

Scaling additive manufacturing to meet demand in industrial mass production is a prominent trend within the current 3D printing industry.

Earlier this year, Utah-based 3D printed parts manufacturer Merit3D announced that it had agreed to deliver ‘the largest ever 3D printer parts order.’ Florida-based adhesives manufacturer Adhesive Technology Corporation placed the order of over 1 million 3D printed parts back in May.

The components in question are hangers for epoxy products and are being delivered at a rate of 40,000 pieces per week. This deal with Adhesive Technology Corporation forms part of Merit3D’s mission to re-shore mass production into the US

Elsewhere, Austrian engineering firm and OEM Incus GmbH recently announced the launch of its newest Lithography-based Metal Manufacturing (LMM) 3D printer, the Hammer Pro40. This new metal 3D printer has been designed to meet demands in mass manufacturing, offers upgraded production capabilities, and can be deployed directly on the factory floor.

The new Incus Hammer Pro40 will be presented for the first time at Formnext 2023 in Frankfurt, between November 7-10.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a high-efficiency air-cooling heatsink created by RICOH’s aluminum Binder Jet Technology (BJT) system. Photo via Ricoh.