3D Printing Industry reviews the Xioneer VXL range of soluble support materials, and the Vortex EZ automated support removal station.

Founded back in 2013, Xioneer started out as a modest 3D printer manufacturer based in Vienna, Austria. The company made a name for itself with its FFF 3D printers and even went on to win the Formnext Startup Challenge in 2016 for its Xioneer Desktop system, featuring a patented tool-changer device.

The firm was eventually acquired by German chemicals company BellandTechnologyAG in 2019, uniting under the present-day Xioneer brand shortly after. The firm now specializes in 3D printing support materials, as well as peripheral hardware such as support removal systems and filament storage boxes.

The unique capability of Xioneer is that they polymerize their materials directly in their factory – meaning that Xioneer doesn’t mix existing polymers but creates its own. According to Xioneer, this allows them to “invent plastics that never existed before”, like the VXL support material.

The Vortex EZ is Xioneer’s flagship automated soluble support removal station. The desktop system aims to fill the accessibility niche, providing an easy and affordable method of post-processing FFF 3D printed parts. Suitable for indoor use, the machine can be used everywhere from offices and schools to workshops and production floors.

Streamlining soluble support removal

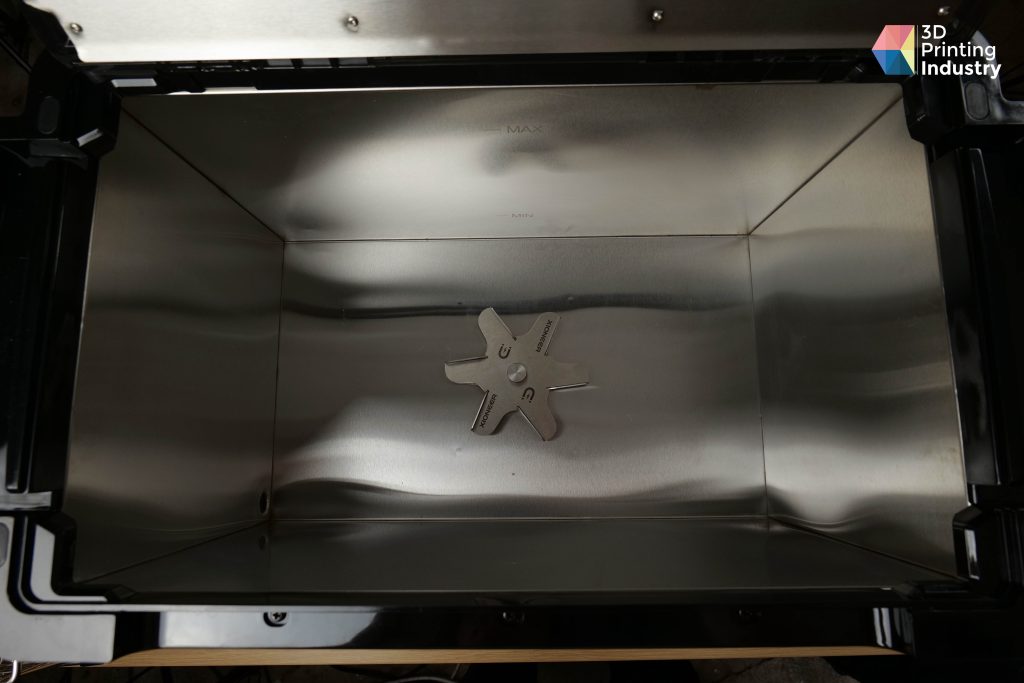

The Vortex EZ operates on two key support removal techniques: heat and continuous fluid agitation (kinetic energy). From the exterior, it looks like a fairly simple piece of kit where the bulk of the frame is a basic stainless steel tank with a matte finish. The body is double-walled for improved thermal insulation and durability, and it can hold up to 36L of liquid solution at a time.

On the front, you’ll find a temperature regulation knob that controls the internal dissolution temperature up to 85°C. It does this via an internal high-power 1,200W heater, which also comes equipped with overheat protection functionality for safety. On the lower side of the Vortex EZ, there is a drainage tap used to drain the cleaning solution from the vat in a consistent and controlled manner, meaning you won’t need to scoop any solvent out manually.

Inside the post-processing station, there’s a part basket that can fit large 3D printed components up to 450 x 250 x 200mm in size. The basket is indeed removable thanks to an easy-to-use clip system so parts can be loaded and unloaded without the user ever having to touch the solvent in the tank.

The Vortex EZ’s fluid agitation mechanism is enabled by an internal brushless motor-powered impeller. This is what provides the mechanical aspect of the support removal technology, helping to dissolve the soluble supports faster.

Owing to the simplicity of the hardware, you’ll also find that the Vortex EZ’s support removal workflow is extremely streamlined. Unlike a 3D printer, there’s no software for print preparation so you can plug the machine in and start the engines in under a minute.

To use the Xioneer, fill the tank with tap water and a few spoons of the company’s own non-toxic VXL-EX washing powder. Place your 3D printed parts in the basket, set the temperature according to the support material, and let the system do its magic. You may need to leave the parts in the solution for anywhere from half an hour to a few hours, depending on the geometry of the parts. Once complete, just rinse the remaining cleaning solution off with tap water and the components are ready to go.

The VXL materials ecosystem

Xioneer offers four soluble support filaments: VXL 70 (1x 500g), VXL 90 (1x 500g), VXL 111 (1x 750g), and VXL 130 (1x 100g).

These acrylate-based support materials don’t dissolve in pure water alone, meaning they’ll need to be used in conjunction with the company’s VXL EX washing powder. The company states that VXL EX is a safe-to-use, and is similar to household detergent, used to wash laundry for instance.

Those that would prefer to use their own third-party support materials are free to do so, as the system is also capable of processing run-of-the-mill filaments like PVA and BVOH.

VXL 70 is Xioneer’s entry-level offering, suitable for low-temperature model materials such as PETG and TPU. The next one up is VXL 90, the all-rounder support filament for mid-temperature model materials like ABS. VXL 111 is compatible with tougher engineering filaments like PA and PC, while VXL 130 is the high-temperature beast designed for the likes of PEEK and PEI.

Benchmarking the Xioneer Vortex EZ

To put the Vortex EZ to the test, we ran a total of 13 3D printed soluble support builds through the machine, covering all four of Xioneer’s VXL support materials. We found all four filaments to be extremely easy to print with and unlike PVA, they’re not all that sensitive to moisture so it’s not a death sentence if they’re left in a room without tight humidity control (we still recommend drying all filaments before using them).

The bonding between the VXL supports and the model materials were also excellent in all cases. Xioneer’s filaments adhere well to both BuildTak build plates and PEI print surfaces, with no warping or delamination issues at all. Using the firm’s recommended temperature settings, each post-processing run took between 1 – 1.5 hours to fully dissolve all the supports.

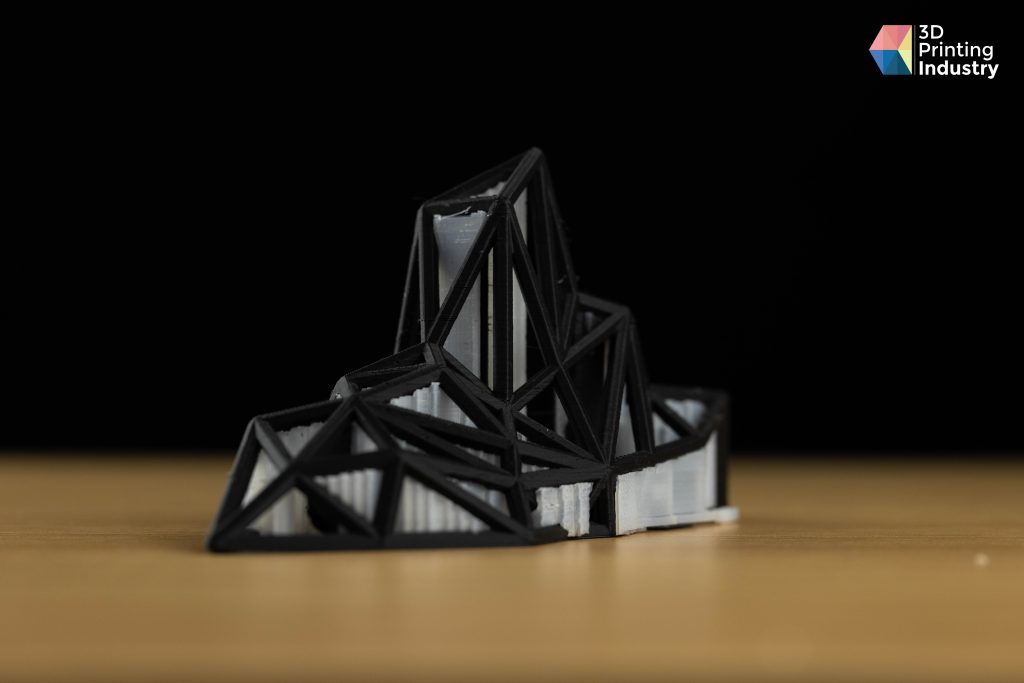

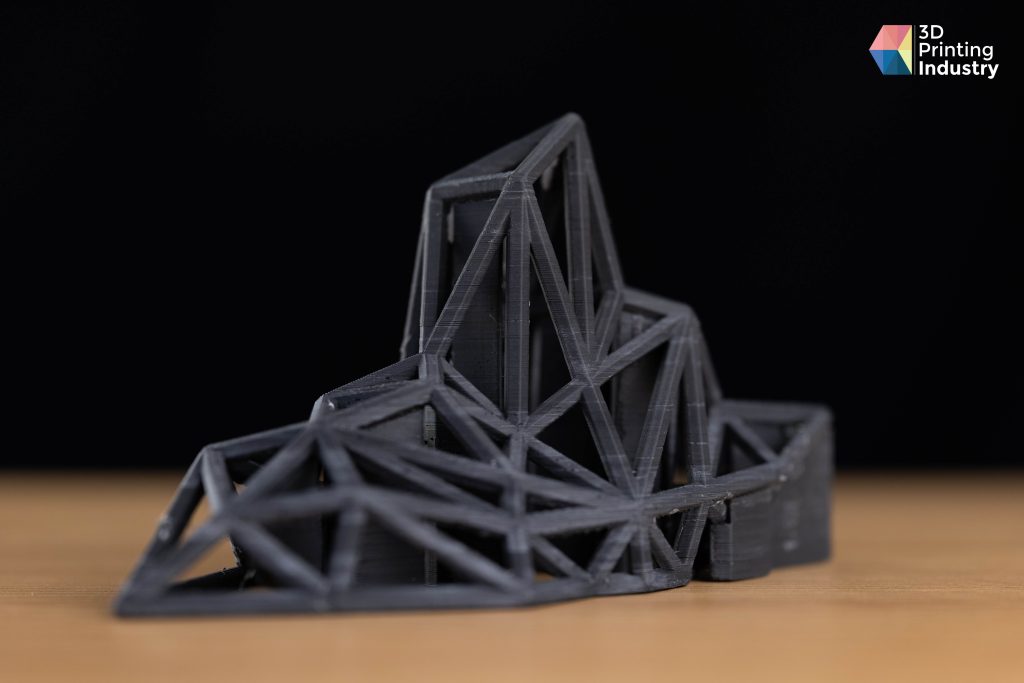

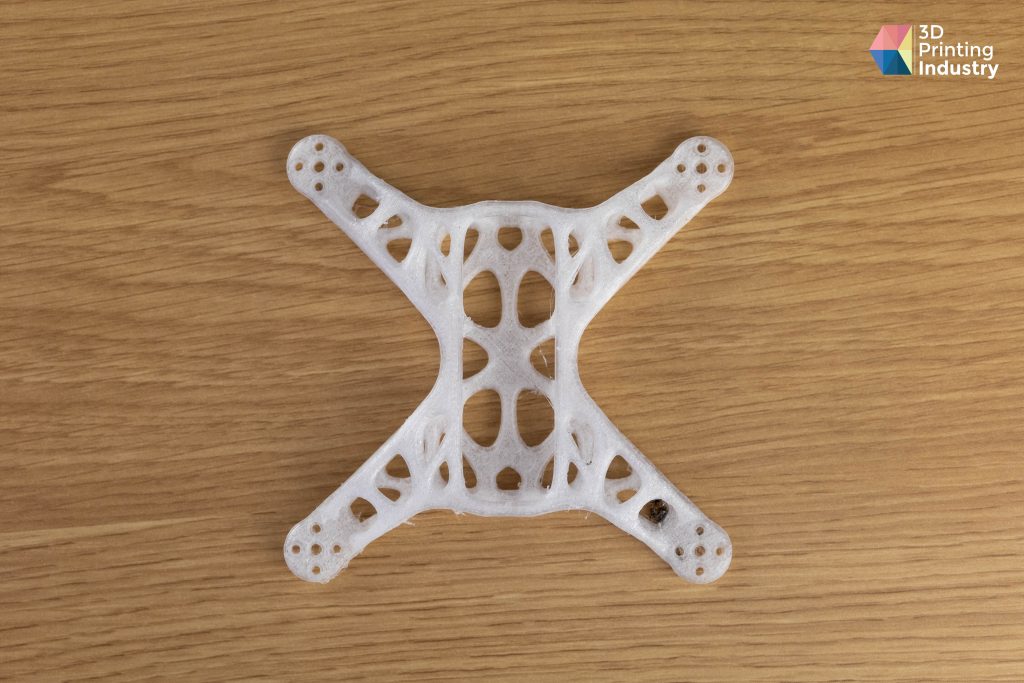

For our first batch job, we processed three VXL 70 parts: a geometric wolf head model (PLA), a complex volume-cell design (PETG), and a topologically-optimized drone frame (PETG).

The Xioneer’s Vortex EZ certainly impressed when it came to the first set of VXL 70 components. The system managed to dissolve all of the soluble supports without affecting the PLA and PETG model geometries. The geometric wolf head and drone frame, in particular, came out the other side extremely clean with almost no traces of there ever being support structures.

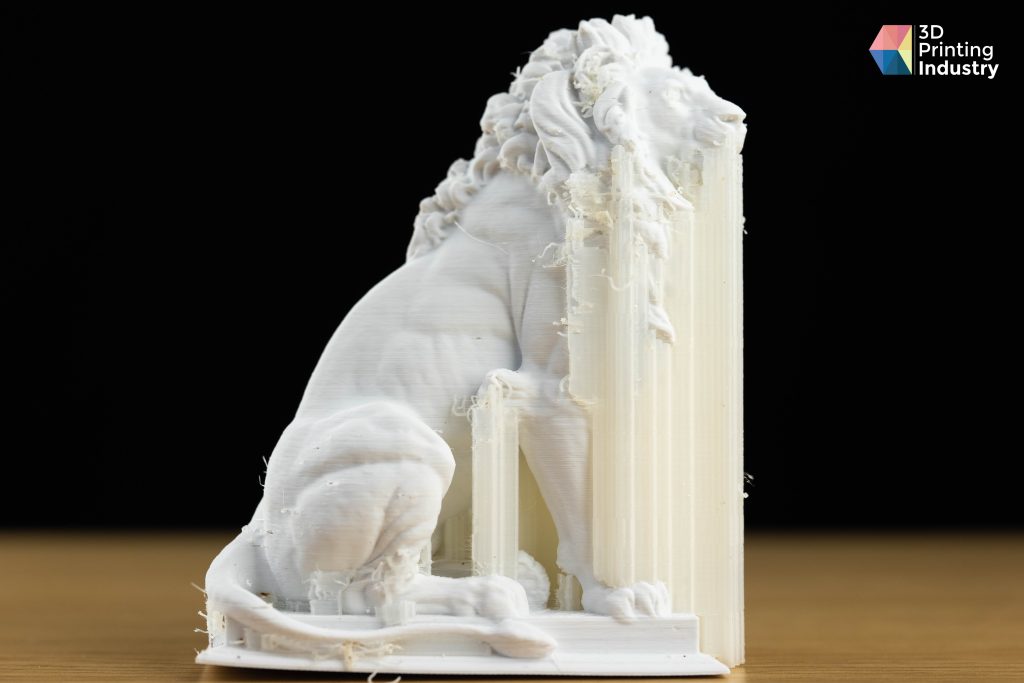

Next up, the VXL 90 batch included a lion sculpture (ABS), wine bottle holder (ABS), cup holder (PETG), and a generatively designed RC car component (PETG).

The VXL 90 batch was even better than the first one, with smooth and residue-free surfaces all around. The support interface zones on the 3D printed wine bottle holder are virtually invisible, while the RC car component looks like it’s hot off a support-free build plate. There are some artifacts on the underside of the lion’s mane and stringing in the geometry of the cup holder, but these can be attributed to non-optimal 3D printing parameters rather than the performance of the Xioneer’s VXL 90.

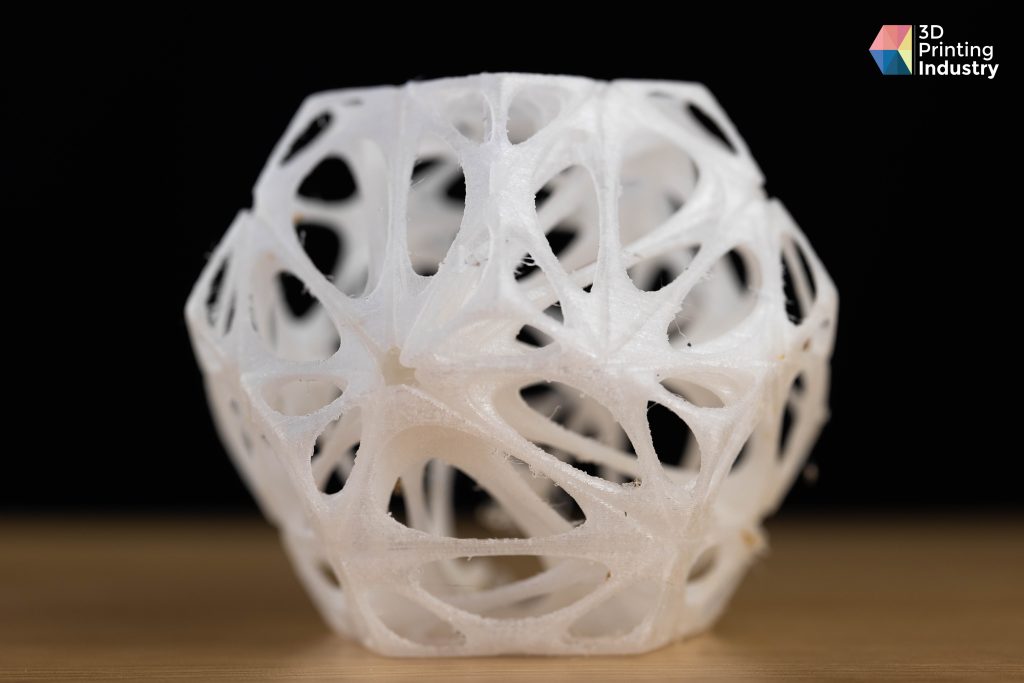

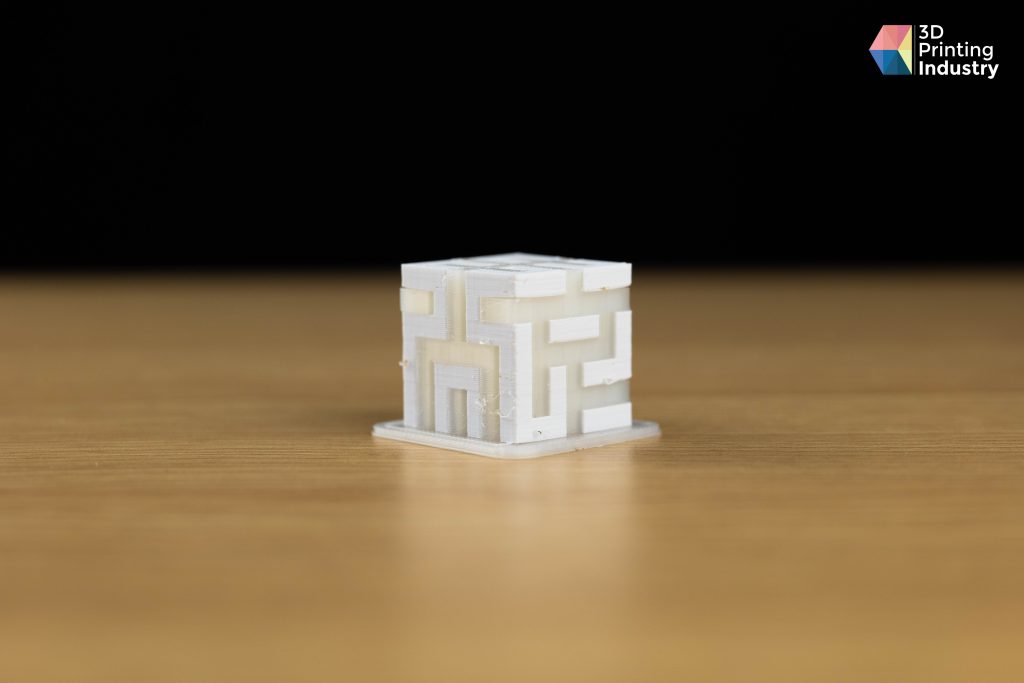

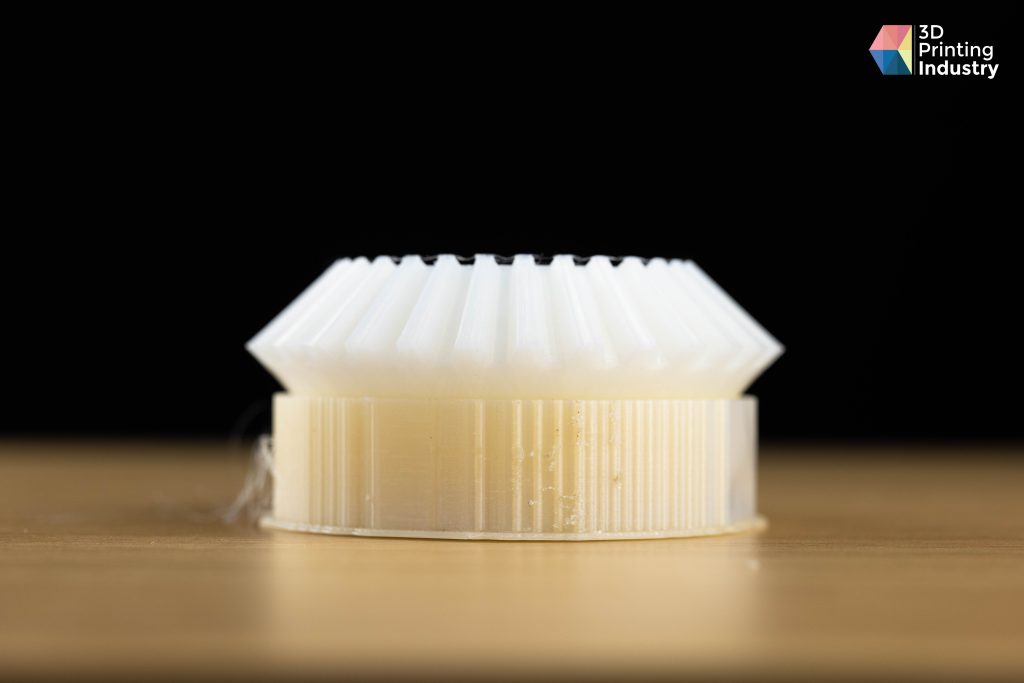

Moving on, the VXL 111 parts comprised a Hilbert cube (ABS), MagSafe phone stand (ABS), bevel gear (PA), and a pushup handle (PA12-CF).

Our penultimate batch of VXL 111 parts turned out excellent on the whole. The Hilbert cube and bevel gear are completely defect-free, while the MagSafe charging stand is perfectly suited to end-use.

One thing to note on the black PA12-CF pushup handle is the residue left behind from post-processing. We believe the previously used VXL-EX solution in the tank could’ve seeped between the layers of the 3D printed part, so it might be a good idea to change the water between uses.

Finally, we post-processed a VXL 130-supported engineering bracket 3D printed in PC. We managed to manually remove the bulk of the supports before submerging the part in the Vortex EZ, but the system made quick work of any residue, leftover stringing, and the hard-to-reach supports that filled the small holes in the part. This was a strong finish for the Vortex EZ, showing just how useful automated support removal can be when it comes to tight cavities.

For comparison, we also printed this part in PC with PC supports a while back. We had a significantly harder time manually removing the PC supports than simply letting the Xioneer do the heavy lifting. The PC-PC model also ended up with an abundance of support scarring on it.

The verdict

In developing the Vortex EZ, Xioneer set out to create a simple and streamlined method of post-processing 3D printed parts. After extensive testing, we can safely say the automated support removal system is as effective as advertised.

Packed with both heat and mechanical agitation mechanisms, the no-nonsense machine is great for those that don’t have the time, energy, or willpower for manual support removal. Equipped with a large part basket and spacious water tank, the Vortex EZ also makes batch processing as easy as pie.

There’s also something to be said about Xioneer’s VXL support filaments. In our experience, they’ve exhibited excellent printability and aren’t as temperamental as the widely-used PVA support material. They’re also compatible with everything from PETG and ABS to PA and PC, and even PEEK, so there’s a VXL offering out there for just about any professional application.

For the cost-conscious 3D printer users out there, there’s also the option to 3D print the bulk of the supports with the model material, while just printing the interface zones with VXL filaments. This way, you can still avoid support scarring while your VXL spools last a lot longer.

Technical specifications

| Basket dimensions | 465 x 275 x 210mm |

| Max part size | 450 x 250 x 200mm |

| Machine size | 640 x 435 x 370mm |

| Weight (without solvent) | 22kg |

| Tank solvent capacity | 11 – 38L |

| Adjustable temperature range | 30°C – 85°C |

| Heat-up time | Approx. 1 hour |

Buy the Xioneer Vortex EZ support removal station here.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Xioneer Vortex EZ and package contents. Photo by 3D Printing Industry.