A team of researchers from the Polytechnic University of Valencia (UPV) has developed a 3D printed alternative to reinforced concrete beams made from recycled plastic.

Although exceedingly strong, reinforced concrete beams are also very heavy as they contain a lot of metal. As a result, moving such beams is often difficult and requires a substantial amount of energy.

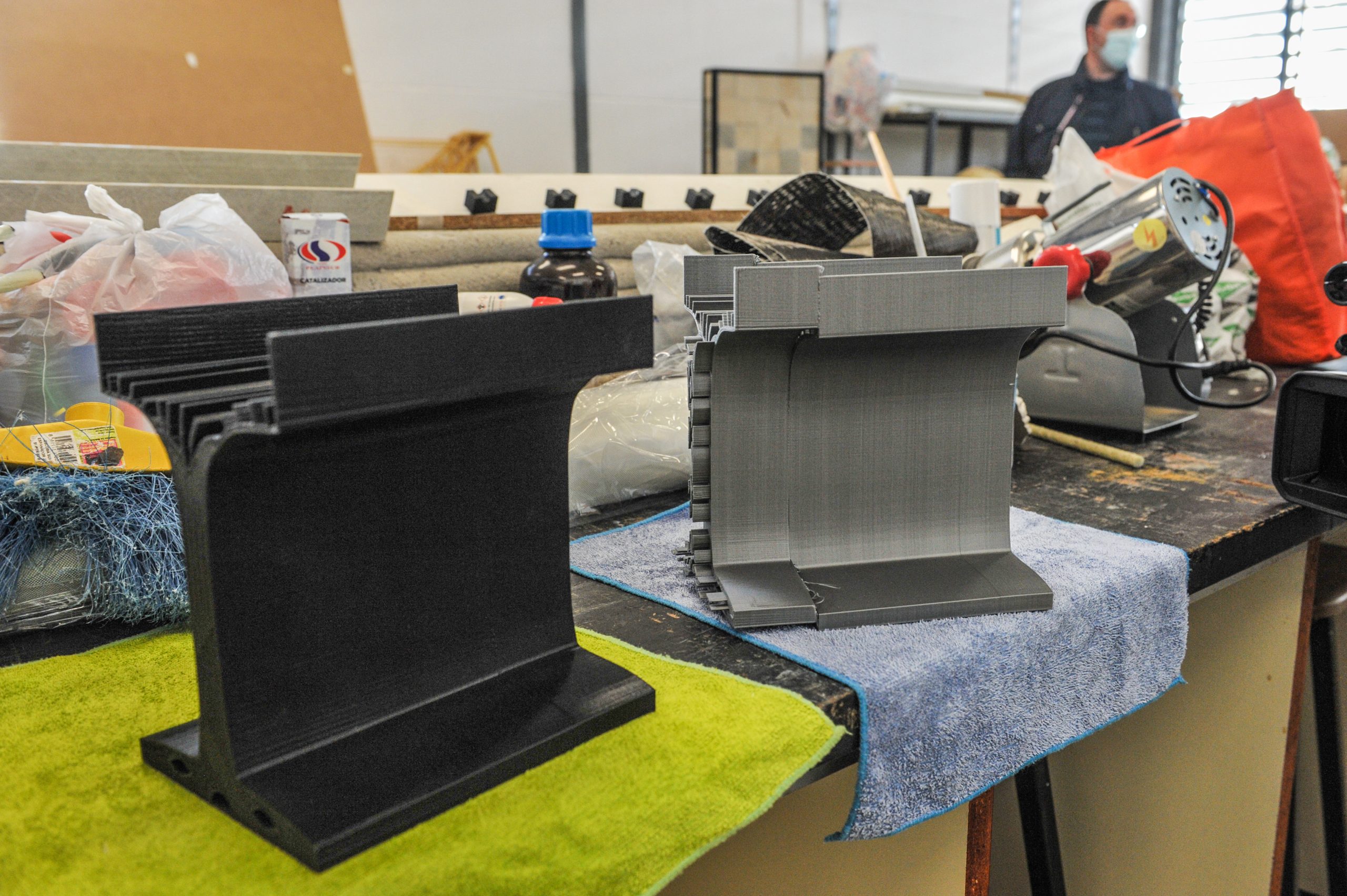

To address these issues, the researchers have designed and patented 3D printed plastic beams that can be assembled like lego bricks and concreted in place, weighing up to 80 percent less than traditionally reinforced concrete or metal beams.

“Our goal was to propose an alternative to the current reinforced concrete structures,” said José Ramón Albiol, Professor at the Higher Technical School of Engineering of Building (ETSIE) at UPV. “These are made up of profiles that are built over the entire length of the part, which requires expensive installations and is hardly transportable.”

Human bone-inspired 3D printed beams

The UPV team embarked upon 3D printing plastic blocks that could be slotted together to form beams, as an alternative to traditional reinforced concrete or metal beams. In order to achieve significant weight savings compared to such beams, the researchers modeled their 3D printed blocks on the internal polymer profile structures of human bones.

The alveolar structure, typical of that found in the epiphysis – or end part – of bones, is made up of a partly spongy layer with a trabecular porous framework and a thick, compact outer layer. The researchers replicated this geometrical structure in their 3D printed blocks to give them strength and rigidity while keeping the parts as lightweight as possible.

The blocks were also printed using recycled plastics as raw material to improve the sustainability of the construction process.

“It is a honeycomb structure, which allows reducing the material plastic used – and therefore its weight – maintaining the structural rigidity,” said Albiol. “And this is what we have transferred to these revolutionary beams, specifically to profiles. It is a very intelligent natural system and its replication in these beams gives them, with a low structural weight, a very high mechanical capacity.”

A lego building block approach

The UPV team has been developing its 3D printed beams over the last three years and patented the system in October 2020.

In addition to the weight-saving benefits of printing the beam components in plastic, the main novelty of the researchers’ system lies in its modularity, whereby the 3D printed blocks can be assembled together on-site to form a longitudinal beam which is then set in place with a layer of concrete.

As a result, large trucks and cranes are not needed to transport and install the beams, saving time and costs regarding labor and materials.

“The system also eliminates the need for costly formwork, allowing you to work without the need to cut traffic in the infrastructure in which you are working,” said José Luis Bonet of the University Institute of Science and Technology of Concrete (ICITECH) at UPV. “Furthermore, this solution reduces the labor and auxiliary resources required, which translates into considerable time and cost savings.”

Additionally, the use of 3D printing means that whole beams can be both manufactured and assembled on-site regardless of location, and beams can be customized to the needs of individual projects when required.

“To be able to customize in-situ the beams allows adapting the characteristics of each one of them to the structural needs of each point of application,” added Miguel Sánchez of the Department of Informatics of Systems and computers (DISCA) at UPV. “The possibility of recycling polymeric materials for the manufacture of the beams also reduces its carbon footprint significantly.”

Advances in concrete 3D printing

The strengths of 3D printing have been increasingly harnessed in recent years within the construction sector to provide enhanced material features, achieve lower manufacturing timescales and costs, and lower the sector’s carbon footprint.

In October last year, researchers from UC Berkeley developed a new method of incorporating 3D printed polymer octet lattices into concrete structures as a reinforcement. They were able to decrease the concrete content in the mixture by some 33 percent, making the overall weight of the structure much lighter while still retaining its load-bearing capabilities.

Elsewhere, researchers at ETH Zurich have used a combination of large-scale FDM 3D printing and casting methods to devise an “eggshell” concrete 3D printing process. The method enables the team to produce complex concrete structures in a more material-efficient way.

More recently, scientists at the Swinburne University of Technology and Hebei University of Technology embarked upon improving sustainability within the sector by repurposing construction waste into 3D printable concrete.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the 3D printed plastic beam alternative to reinforced concrete. Photo via UPV.