Hyderabad-based Birla Institute of Technology & Science (BITS) researchers have unveiled a novel approach to detect and monitor diabetes.

Through the utilization of 3D printing technology, the researchers crafted a portable device with the ability to analyze glucose and lactate concentrations present in sweat samples. Documented in Elsevier and with backing from the Telangana State Council of Science & Technology (TSCOST), the research demonstrated the inherent promise of sweat as a key analytical substrate, especially for the ongoing tracking of glucose levels in those suffering from type 1 and type 2 diabetes.

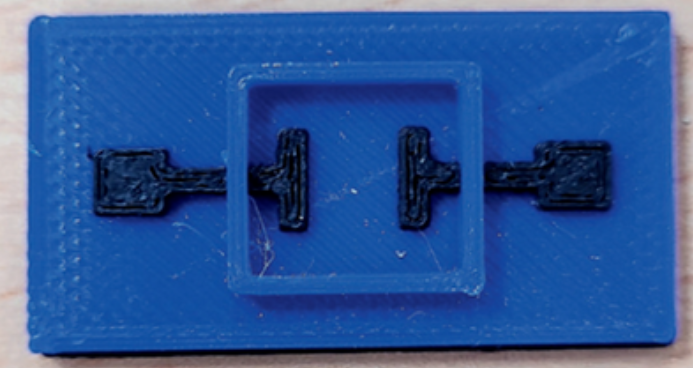

As outlined by Professor Sanket Goel, crafting this device involved a fusion of 3D printing, CO2 laser technology, and electrodes constructed from graphene. Additionally, students were responsible for extracting graphene in-house as part of the development. “The system’s non-invasive nature eliminates the need for blood samples to gauge glucose levels. It can work with blood too. But, the novel innovation is that it takes sweat sample to detect lactate concentration,” the professor told Times of India (TOI.)

A low-cost and effective alternative

The professor emphasized the mechanism through which this device identifies lactate levels. He said this device operates based on Electrochemiluminescence (ECL). The device functions by emitting an electrical signal upon the introduction of sweat as input. Subsequently, a chemical reaction occurs, resulting in the emission of light as an output. Through the measurement of light intensity, it becomes possible to ascertain the concentration of lactate.

Additionally, by also using machine learning, researchers were able to determine lactate concentrations crucial for treatment. They designed a portable device connecting to smartphones, displaying metabolite data via an app. According to the researchers, the device is being developed into a wearable version for ongoing monitoring. In collaboration with a company (currently anonymous), they plan to launch the device in 6-9 months, with an estimated cost of Rs. 300-400 ($3.63 – $4.84) per unit in bulk.

3D printing enhances diabetes monitoring and treatment

Researchers at the UK’s Staffordshire University developed a cost-effective 3D printed insole with integrated sensing capabilities to prevent diabetic foot ulcers. The 3D printed insoles used tunable structures to detect pressure points while walking, aiding clinicians in identifying early signs of ulcers in vulnerable patients and avoiding amputations. Comprising conjoined hexagons, the flexible TPU-based design shielded diabetic feet from pressure. Over time, microstructures accumulated damage, aiding in mapping vulnerable areas. After 2,000 test cycles, the insoles proved durable, with a pressure threshold of 252 kPa.

Researchers at the National and Kapodistrian University of Athens developed a 3D printed device allowing diabetics to monitor blood sugar levels using only sweat and a standard smartphone. Employing a Flashforge Creator Pro 3D printer and conductive filament, the team fabricated an electrochemical ring (or ‘e-ring’) with three plastic electrodes. Once connected to a mini-circuit board, the sensors accurately tracked glucose levels using biomarkers, providing a less invasive self-testing option as compared to traditional glucometer needles. The approach shifted to sweat-based biomarkers due to limitations in conventional enzyme-based sensors. Gold-plated sensors, connected to a Samsung J5 smartphone, displayed precise readings following sugar-induced “artificial sweat” tests. This method has the potential for accessible, precise, and in-house 3D printed glucometers.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the researchers employed machine learning to determine precise lactate concentrations. Image via BITS.