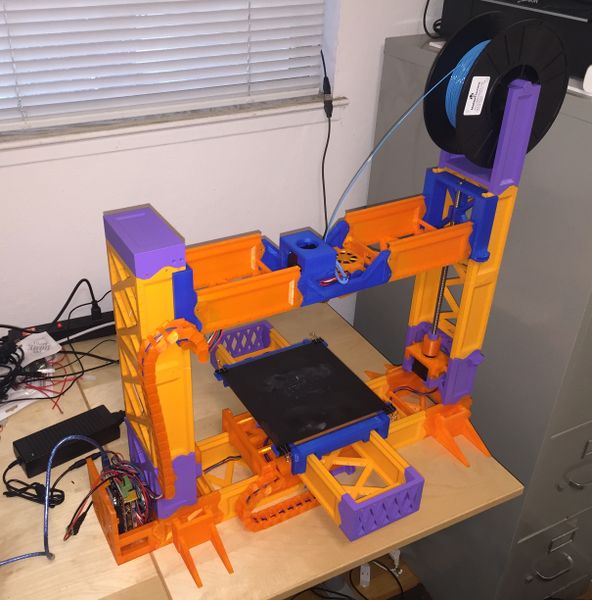

The open source RepRap project was established with the goal of, one day, creating a 3D printer capable of 3D printing all of the parts necessary to building an exact replica. While we may still be a bit of a ways away from a pure self-replicating 3D printer, the Snappy, by RepRap member Revar, is a RepRap 3D printer that is helping the community to inch ever so close to that goal. By taking a unique approach to its design, Revar has developed a printer that has a very minimal number of components that can’t be 3D printed.

One on the printer’s many unique design components is the reason for the name, “Snappy”, as this RepRap is made up of components that simply snap together. This allows for smaller pieces to be printed as part of a larger frame, while eliminating the need for non-printable hardware to keep the structure together. While the Snappy does require metal rods for the Z axis, Revar eschews using belts and bearings in favor of a rack and pinion system for the X and Y axis. In all, the Snappy is 73% 3D printable and consists of 61 printed parts that take approximately 150 hours to print. In addition to the printed parts, motors, electronics, a glass build plate and one 686 bearing are required to complete the setup.

If you want to give it a shot check out Snappy’s RepRap page for all of the information, as well as the downloadable files. All we need now is for companies like Voxel8 to advance the integration of electronics into 3D printing and, maybe someday soon, we may see a pure self-replicating 3D printer.