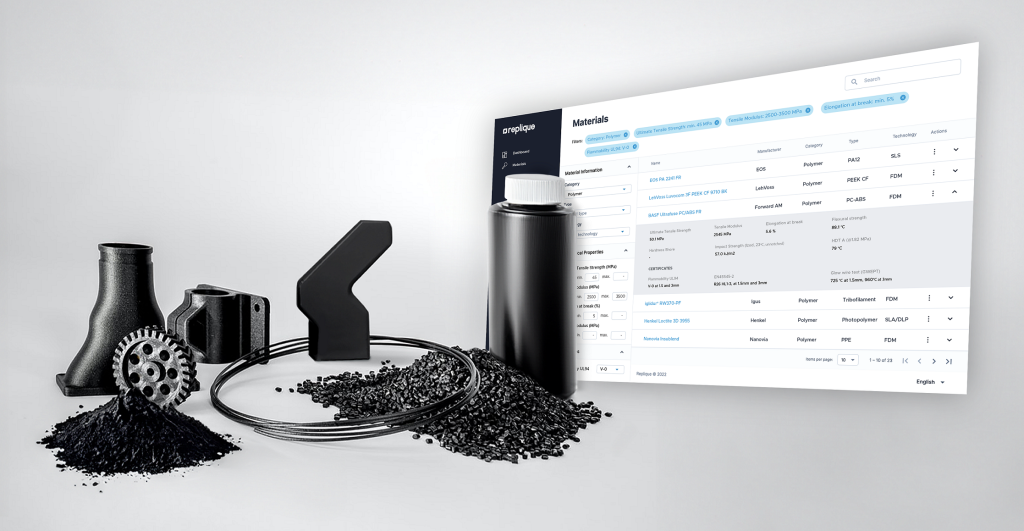

Formnext 2023 will see Replique launching a comprehensive and open material database for 3D printing.

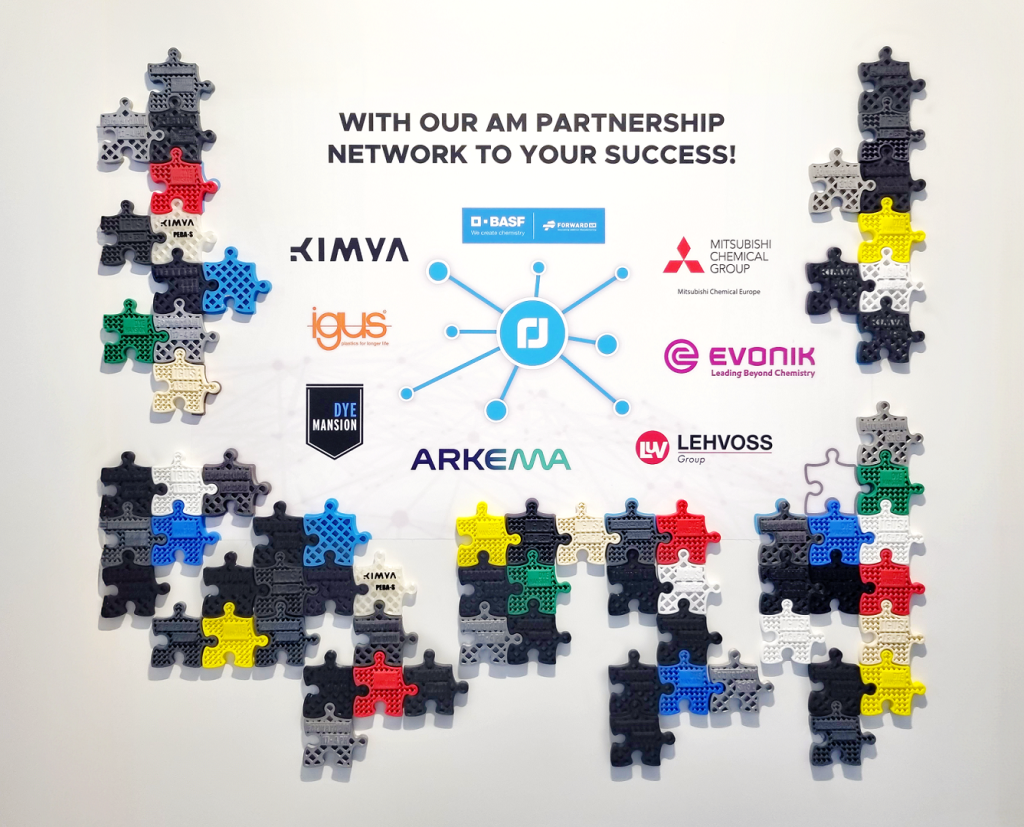

Backed by trusted material partners like Arkema, Evonik, DyeMansion, and more, this initiative streamlines the use of additive manufacturing (AM) for businesses and can be explored at Replique’s booth in Hall 12.1, Stand #A107. Replique emphasizes that effective material selection is crucial for success in additive manufacturing (AM) projects. Traditionally, this process has been labor-intensive and heavily dependent on manual research. Replique’s material database now offers users an intuitive platform to choose the most appropriate materials for their specific applications. This not only saves time and resources but also ensures the quality of additively manufactured components in meeting material requirements.

Dr. Henrike Wonneberger, CEO, and Co-Founder of Replique, explains, “Through our daily engagement with material data, we have built a rich knowledge hub that we are now eager to share with the wider community. The launch of our material database represents another significant step in our mission to drive the industrialization of additive manufacturing and provide comprehensive support to our customers at every stage of their journey.”

An open and collaborative resource for the 3D printing community

Within the material database, a variety of filters are available, covering technical specifications, compliance with industry standards, and application categories. The aim is to facilitate easy access to reference cases and certificates in the future, reducing the necessity for time-consuming inquiries. This “invaluable resource,” as described by Replique, has resulted from collaborations with respected material manufacturers over the past year.

Replique’s material database extends to 3D printer manufacturers, service providers, and other companies. They can both use and contribute to the database, enhancing their work and services with material insights. What distinguishes this database is its open design, allowing material data access through the Replique platform and an upcoming API interface. This user-friendly approach ensures convenient data access, protected by a free password barrier.

Standing as a central element in Replique’s extensive ecosystem, the material database is complemented by a range of services, including Additive Marking, which is specifically designed to enable the traceability of 3D printed parts. This integrated strategy ensures that Replique’s customers can easily access vital information and services via a single, unified interface—the Replique platform.

Replique’s journey in 3D printing

France-based rail manufacturer Alstom adopted Replique’s on-demand 3D printing services for its industrial series production. The company digitized a segment of its supply chain, highlighting manufacturing flexibility, shorter lead times, and cost-efficiency as primary drivers for the move. With Replique’s support, Alstom produced small batches of metal components for its trains in a decentralized manner, enhancing its ability to meet the specific requirements of clients worldwide. Consequently, through this partnership, Alstom received and incorporated its first assortment of 3D printed train parts, visibly including stainless steel door stoppers.

Replique partnered with Miele, a German appliance maker for decentralized 3D printed accessories. Replique’s platform is integrated into Miele‘s online store for swift, cost-effective accessory provision. Claiming a vital role in implementing Good Manufacturing Practice (GMP) for 3D printing food-contact polymer components, they began with three accessories: a coffee clip, a borehole cleaner, and a vacuum attachment separator.

Who will win the 2023 3D Printing Industry Awards? Make your nominations now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Launch of Replique’s Material Database at Formnext 2023. Photo via Replique.