UK-based engineering firm Renishaw has supplied its RenAM 500Q AM system to Domin, a fluid power systems manufacturer.

Domin aims to develop and produce a range of highly competitive servo-proportional hydraulic valves. Its objective is to contribute to environmental sustainability by targeting a reduction of one gigatonne of CO2e emissions by 2030. To meet the stringent requirements of control systems in sectors such as automotive, aerospace, and manufacturing, the company has created a new line of high-performance hydraulic valves. Domin will utilize Renishaw’s RenAM 500Q system to manufacture these valves at its newly established Technology Centre located in Pucklechurch, near Bristol. This strategic move involves consolidating its manufacturing operations from multiple facilities, including one in Poland and two in the UK.

“We designed these servo valves to achieve a better-performing, more sustainable product at a lower price point,” said Marcus Pont, CEO at Domin. “The success of these valves in a broad range of applications means demand is outpacing what we can supply. Renishaw is the go-to choice for coupling productivity with quality, and we expect that the increased capacity the new AM system provides will allow us to maintain low production turnaround times and deliver consistently high quality to our growing customer base.”

Leveraging metal additive manufacturing to create high-performance hydraulic valves

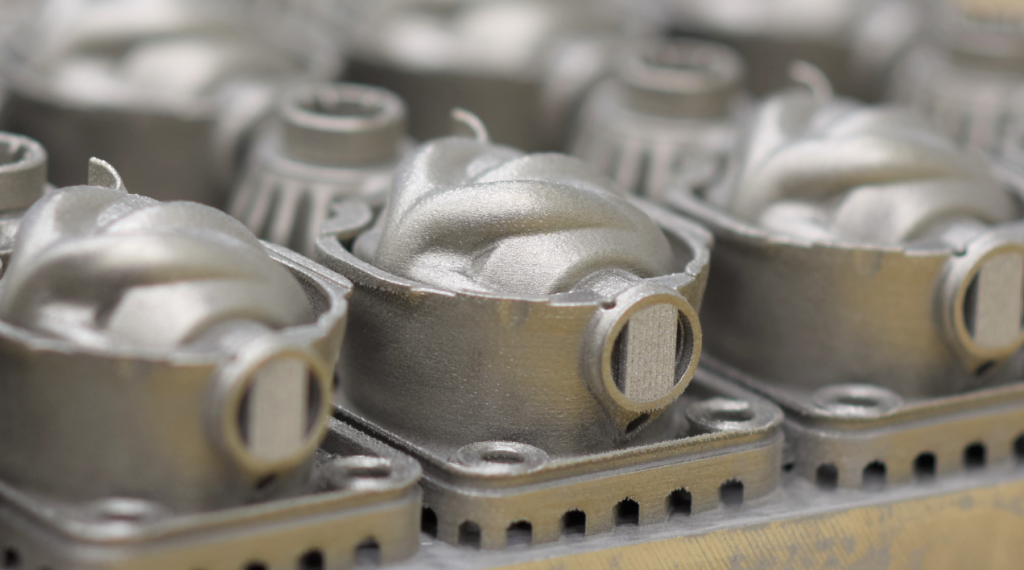

Domin utilizes Metal AM to design complex geometries with internal features, enabling highly efficient stiff structures not achievable through traditional manufacturing. This approach produces single parts with a strong strength-to-weight ratio and reduces waste. The manufacturer has also combined additive manufacturing with technologies like high-speed motor control, modern electronics, big data, and connected technology to create four servo-proportional hydraulic valves.

Renishaw’s 500Q system includes an advanced gas flow system designed to effectively eliminate process emissions along the laser path. This feature contributes to maintaining a stable processing environment, which has significantly improved quality standards. As a result, the system has surpassed the quality levels typically associated with metal AM technologies, says Renishaw.

“With four high-power 500W lasers able to access the whole powder bed surface simultaneously, the RenAM 500Q system achieves significantly higher build rates than previous systems, which vastly improves productivity and lowers cost per part,” said Bryan Austin, Director of AM Sales at Renishaw. “This productivity enabled Domin to take its range to market competitively. Their valves require high-precision machining to achieve tight tolerances and accurate positioning and use high-grade materials to ensure strong chip shear and durability. Domin wants to manufacture them at scale and our RenAM 500Q system makes meeting these requirements possible.”

Sustainable practices in the additive manufacturing sector

At the Formnext 2022, industrial manufacturing firm Siemens, and EOS, a developer of powder bed fusion (PBF) 3D printers, showcased their sustainable 3D printing applications. Siemens demonstrated how 3D printing’s design freedoms helped reduce the footprint of automotive grippers. Meanwhile, EOS introduced two eco-friendly materials. Their carbon-reduced PA 2200 contained nearly 45% less CO2 compared to its previous formulation. Additionally, EOS launched a climate-neutral PA 1101 that was bio-based without compromising on quality.

Chennai-based start-up Tvasta Manufacturing Solutions collaborated with India Cements to develop a sustainable construction 3D printing material. Under a strategic collaboration deal, the companies exchanged technologies and conducted joint research and development to create an eco-friendly cement formulation. With prior experience working together on projects for private clients and the Indian Air Force, the companies extended their partnership to enhance the resource efficiency of construction practices in India.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Hydraulic valves by Domin. Image via Renishaw.