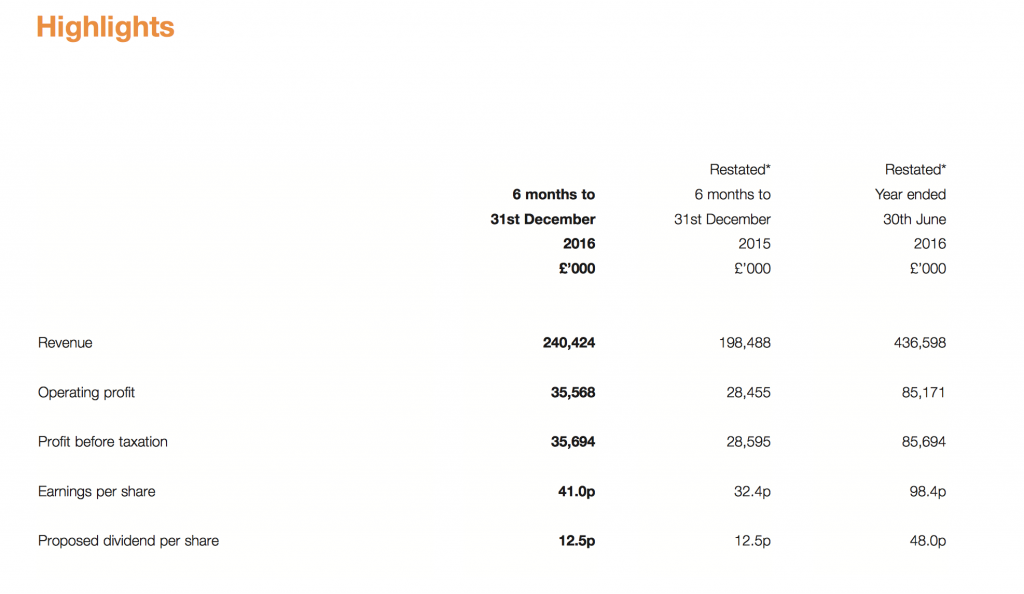

British engineering company Renishaw (LON:RSW) have released interim results for the last six months of 2016 from July to the 31st December. When compared to the same period in 2015, total revenue is up 21% from almost £200m to over £240m, see table below:

Renishaw measures its business in two segments: metrology, i.e. ‘the science of measurement’ and healthcare applications, both of which are supported by additive manufacturing.

Additive manufacturing in metrology

The metrology section involves precision engineering of industrial components, and includes metal additive manufacturing as one of the key proponents. From the Chairman’s statement, interim results show:

Revenue in our metrology sector for the first six months was £227.1m, compared with £184.9m last year. Operating profit was £41.6m, compared with £30.6m for the comparable period last year.

3D Printing Industry editor-in-chief Michael Petch spoke to Marc Saunders, Renishaw’s director of Global Solutions Centers, about the industrialisation of the company’s metal additive manufacturing sector at IMTS 2016.

In the interview, Saunders comments, “I think the vision really is that additive is going to take its place as mainstream manufacturing process in the next few years for making advanced parts.”

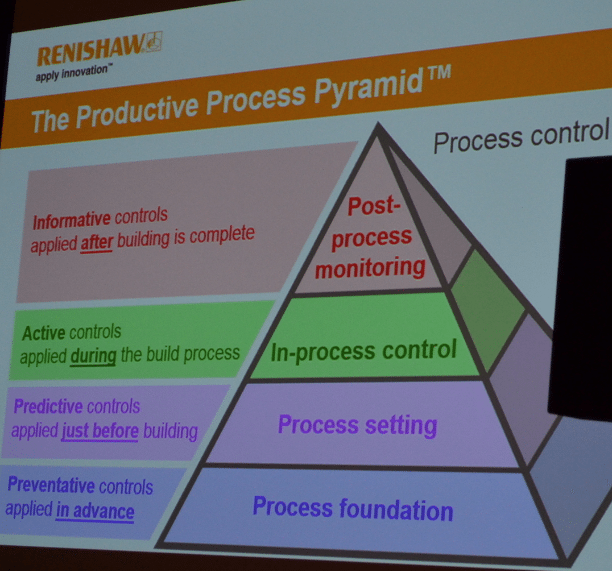

At Renishaw’s IMTS presentation, Saunders also introduced the concept of a productive process pyramid to make the most of additive manufacturing capabilities, managing the steps from design for additive manufacturing (known as DfAM), to rapid prototyping.

In an assessment of the principal risks and uncertainties to Renishaw’s business, the report also sites that: “The Group is applying its measurement expertise to grow its healthcare and additive manufacturing business activities” as one level of mitigation against the current trading levels and order book implications of Brexit.

Additive healthcare

Additive manufacturing is equally as important to Renishaw’s healthcare subsector. The Chairman’s statement reports:

Revenue in our healthcare sector for the first six months was £13.3m, compared with £13.6m last year and there was an operating loss of £6.0m, compared with a loss (restated) of £2.2m for the comparable period last year.

Listed in the company’s product range are 3D scanners and CAD software, used for additive dental applications as discussed by 3D Printing Industry through the company’s integration of a Polygonica software toolkit.

The report also lists a focus on craniomaxillofacial custom-made implants additively manufactured from titanium to reconstruct parts of the skull.

Renishaw’s full interim report can be found on the company’s website.

We will have more on this story later today. If you want to be the first in the know, be sure to find us on social media. We are on facebook as 3DPrintingIndustry and Twitter @3Dprintindustry.

Nominations for the first annual 3D Printing Industry Awards are now open.

Featured image shows Renishaw bottle openers 3D printed in Titanium. Photo via: Renishaw