Relativity, the California startup in pursuit of the world’s first entirely-3D printed rocket, has made two advances in terms of IP and personnel.

In a patent published November 29 2018, the company has been granted the rights to a method of adaptive control for its large-scale Stargate metal 3D printer.

In addition, Relativity has recently hired three former executives of competing private space exploration companies SpaceX, Blue Origin, Virgin Orbit and Aerojet Rocektdyne.

“Our progress towards launching the first 3D printed rocket is fueled by a deeply experienced team that has built and scaled other space companies,” comments Tim Ellis, Relativity’s CEO.

“[…] These executive appointments, combined with our recent patent grant, are great indicators of Relativity’s market momentum.”

The 95% 3D printed rocket

Relativity’s first rocket is named the Terran. Powered by the liquid-oxygen (LOx) methane engine AEON 1 this vehicle, when complete, will be capable of transporting a payload of up to 1,250 kg to a low Earth orbit of 185 km. To high altitude, 1200 km/sun synchronous orbit, the rocket will be able to carry up to 700 kg.

The AEON 1 engine, which has already undergone over 100 test firings is composed of 100 components, a fraction of the number of parts for a typically produced engine; This part, as with a full 95% of the current Terran rocket, is built on the Stargate 3D printer.

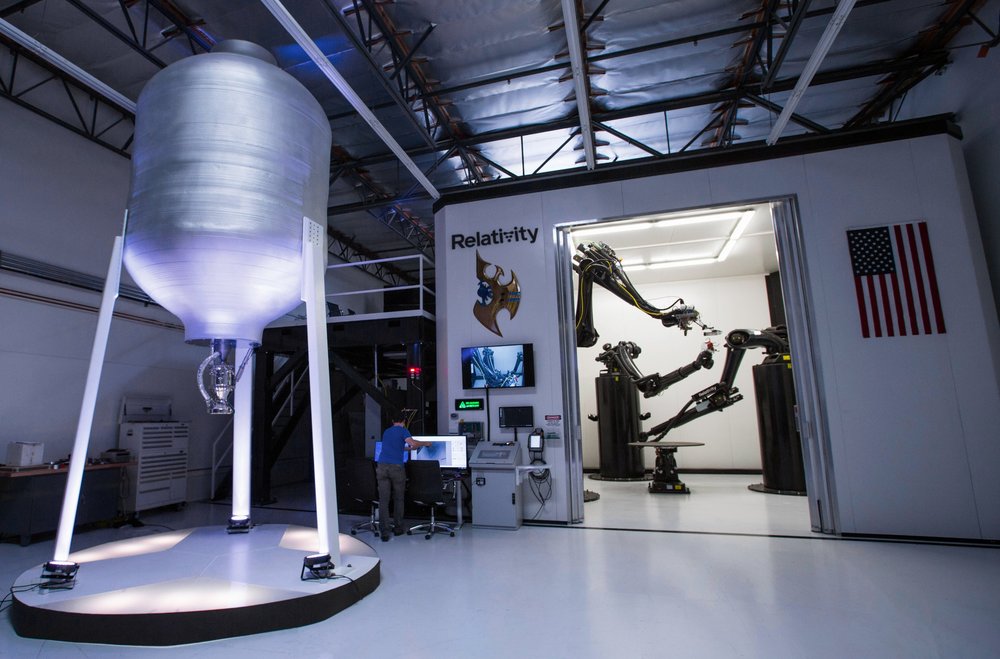

Operated by robotic arms, the Stargate has an entirely salable build volume. One of the largest parts it has built so far is a fuel tank measuring 7 feet wide and 14 feet tall.

Relative to the output rate of the Stargate, Relativity estimates that it can 3D print an entire Terran rocket in under 60 days.

Relativity’s machine learning patent

The most recent patent award to Relativity is for a machine learning process capable of automatically detecting and correcting faults within the additive manufacturing (or welding) process.

The method was invented by Ellis, Relativity CTO Jordan Noone and Edward Mehr, the Program Manager for Relativity’s Stargate system. It specifically pertains to the monitoring of a wire-fed metal 3D printing process, as opposed to powder bed additive manufacturing.

In order to create self monitoring, and correcting, capabilities within this 3D printing process, the team creates a software combining a four grouped data elements. Firstly, Finite Element Analysis (FEA) simulation data of the build. Secondly, in-situ laser beam interferometry data generated from probing the build. Third, post-build inspection data from previous jobs. And the fourth, unspecified, “other training data” allowing the machine to build its understanding.

By comparing its current job with all of this information, the 3D printer is programmed to take action should something seem incorrect. By doing so, the team ensures a smoother build, with less material wastage and potential failures.

A number of similar methods are currently undergoing development at research institutions and companies around the world, not least Lawrence Livermore National Laboratory’s high speed imaging which can detect failures using just 10 ms of video. And so for Relativity, understandably, this is a significant advance toward its mission. “The grant of this patent is a recognition of how our autonomous 3D metal printing technology can quickly and iteratively optimize rocket production on Earth and other planets,” comments co-inventor Noone.

“[It] is a pivotal step towards our technology differentiation and leadership in the market.”

Built by veterans of the aerospace industry

To date, following $35 million Series B funding from 2018, Relativity has raised an estimated $45.1 million, some of which has been used to grow the company’s manpower. According to recent reports for the company, in the past year it has taken on 50 new members of staff, raising its employee base from 14 to 64.

The company’s most recent hires are Tim Buzza, Josh Brost and David Giger.

Buzza joins Relativity as Distinguished Engineer after an 8 month term as Advisor to the company. His career, which began in 1988, started with a 14 year term as Advanced Research and Development at Boeing, and went on to encompass senior roles at Space Exploration Technologies and Virgin Orbit.

Brost, is Relativity’s new Vice President of Government Business Development (which already includes a deal with the U.S. Air Force.) Brost joins the company following almost 9 years in a similar role at SpaceX.

And Giger, the former Senior Director of Dragon Engineering at SpaceX, is Relativity’s Vice President of Launch Vehicle Development for the Terran 1.

Aiming to maintain the momentum of its employee appointments ahead of the Terran’s first orbital laucnh in 2020, there are still several open positions available at Relativity HQ and its test facility in Mississippi.

If you’re a company looking for candidates with additive manufacturing expertise, create a profile on 3D Printing Jobs and start advertising now. Looking for a new opportunity? Join 3D Printing Jobs to start applying for new roles now.

Decide your Aerospace/Automotive Application of the Year in the 2019 3D Printing Industry Awards before voting opens in March. For more of the latest applications news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Featured image shows ignition of the Relativity Space Aeon engine. Photo via Relativity.