Industrial manufacturing firm Siemens has announced at RAPID + TCT that it is ramping up its efforts in AM with the aim of “accelerating the transformation” of the American manufacturing industry.

Siemens says it has prioritized supporting the local AM machine builder community and is utilizing its “world-class” motion control, automation hardware, digitalization software, and technology expertise to aid machine builders. Located in Charlotte, North Carolina, Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) will serve as an ecosystem platform for machine builders, users, and additive design engineers.

“We are on the threshold of a new frontier in American industry, where the implementation of additive manufacturing will bring fundamental changes to the landscape, end-to-end, from product to machine to manufacturing. Siemens is very excited to be at the forefront of this process,” said Steve Vosmik, Head of Siemens Additive Manufacturing in the United States.

Comprehensive AM solutions and the launch of an advisory board

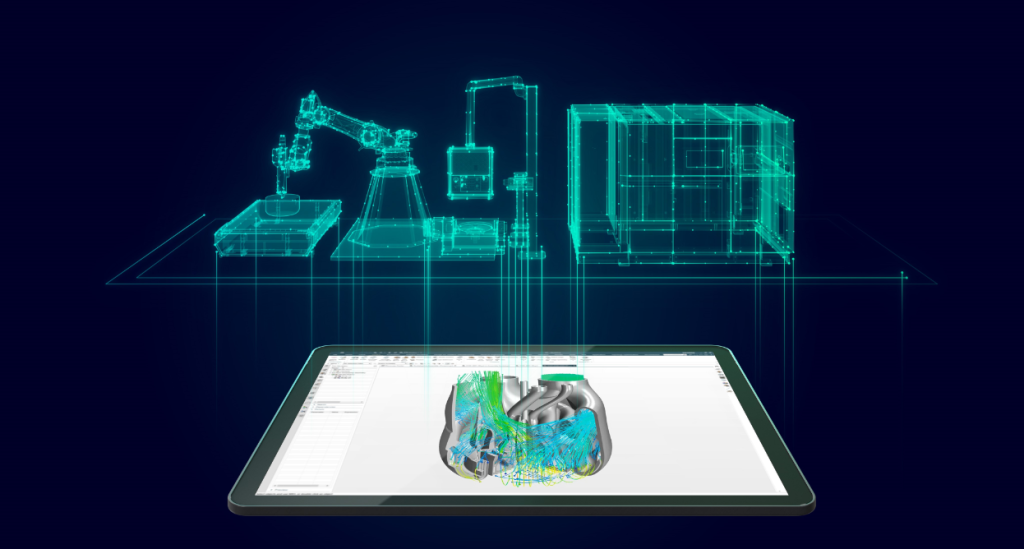

Siemens believes it can provide comprehensive solutions to both AM job shops and Tier One production facilities, encompassing everything from product design software to digital twin machine simulation, and virtual execution of manufacturing methods. This includes complete data feedback into the design protocol, enabling necessary adjustments to be made prior to any machine building. Vosmik said, “This comprehensive suite of software and motion control hardware offerings makes Siemens a viable partner at every step of the AM process.”

Siemens is expanding the technological capabilities of CATCH by procuring and installing an ExOne/Desktop Metal Production System and Meltio Robotic System, featuring the onboard Siemens SINUMERIK RunMyRobot application, to incorporate metal binder jet technology. With the SINUMEIK RunMyRobot application, it becomes possible to control the kinematic path of an industrial robot, facilitating its integration with the CNC machine.

To better support the rapidly expanding AM market, Siemens is also creating an Additive Manufacturing Advisory Board consisting of distinguished industry leaders in AM from diverse technical backgrounds and industries. This board will offer guidance to the company in its efforts to meet the evolving needs of the AM market. “We are looking forward to engaging and collaborating with this talented group of industry experts as we move ahead together into this exciting new world of manufacturing in America,” added Vosmik.

According to Siemens, its AM technologies have the potential to assist the American industry in “re-imagining its products, re-inventing its manufacturing processes, and rethinking its overall business strategy”.

“More than 100 machine builders from around the world are implementing Siemens automation solutions to industrialize their machines,” said Rajas Sukthankar, Vice-President, of Motion Control, Siemens Industry, Inc. He continues, “Now it’s time to support even more customers and accelerate their transformation from single machines to series additive manufacturing factories. North America is heading in this direction.”

Scaling the AM sector with expansions

Industrial parts sourcing platform MakerVerse expanded its advanced manufacturing offerings by collaborating with industry leaders, improving enterprise integration, and adding new serial manufacturing capabilities. The company provided a platform that combines AI-powered instant quotes with a verified global supply chain and has augmented its supply chain to include CNC. Additionally, MakerVerse also announced that it offers additional expertise for serial production orders, with experts collaborating closely with clients to create, align, and oversee the entire manufacturing and quality plan from beginning to end, ensuring consistent, high-quality output for complex projects.

UK-based 3D printer reseller EVO 3D expanded its EVO TECH 3D Robot Printing Cell range with the addition of new partners ADAXIS and REV3RD. The company launched its pellet 3D printing packages last year, offering users the flexibility to use various robot, extruder, and software combinations to gain high throughput and production. With its existing offerings, which include robot manufacturer KUKA, robotic 3D printing software developer Ai Build, and Canadian OEM Dyze Design, EVO 3D aims to provide a durable EVO TECH 3D Robot Printing Cell lineup. The company claims these French-Swedish robotics software companies and large-scale 3D printing start-ups were “meticulously selected” to expand their offerings.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Siemens Additive Manufacturing key visual. Image via Siemens.