Prototyping company Quickparts has adopted the CO-AM platform from additive manufacturing software developer Materialise. The tool will be used to oversee distributed manufacturing flows.

Quickparts’ conventional and additive manufacturing capabilities will be supported by CO-AM, which links with current production systems. Ziad Abou, CEO of Quickparts said, “Adopting CO-AM within Quickparts’ manufacturing operations will enable us to streamline our distributed global production facilities and modernize our capabilities with efficiency so we are able to achieve the fastest lead times in the industry.”

“We look forward to our collaboration with Quickparts to create and grow their software solution for high-quality, on-demand manufacturing through CO-AM,” said Bart Van der Schueren, CTO of Materialise.

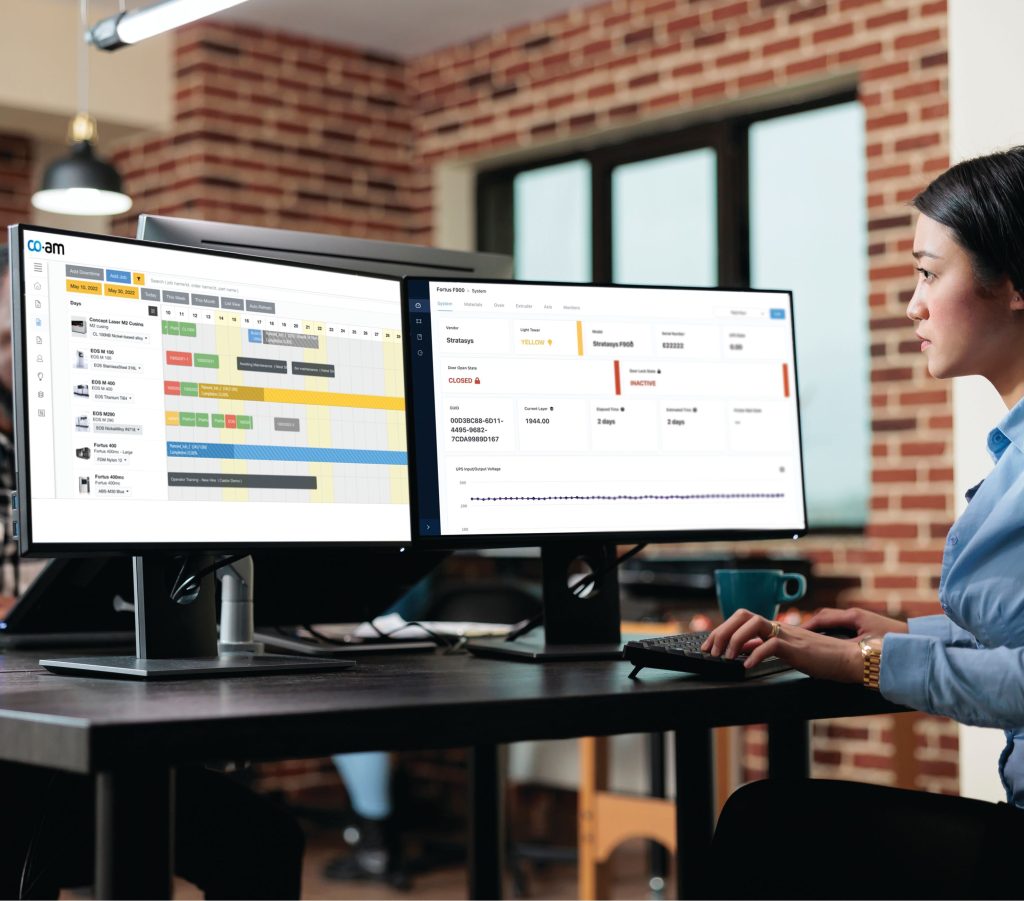

Qucikparts benefitting from the adoption of the CO-AM platform

Quickparts operates seven worldwide design and manufacturing centers in Europe and North America. Its distributed manufacturing network necessitated implementing a software solution capable of linking all sites and incorporating conventional and AM technologies. Quickparts began implementing CO-AM at their US sites in Seattle and Lawrenceburg at the end of 2022, and the framework will be expanded to additional locations in the second quarter of 2023.

“Once CO-AM is integrated, we can process orders faster, which allows us to improve our cost structure through fleet optimization and machine utilization. It gives us, and our customers, traceability to every part along the manufacturing process so we can realize the highest quality standard with all of our parts,” added Abou.

Quickparts will use CO-AM to automate processes, simplify order-to-cash operations, and safely maintain production throughout distribution manufacturing sites. Quickparts will be able to gather and access production data, track and enhance workflows, and accomplish a level of efficiency that will assist in saving its customers time and money.

Customers in the aerospace, automotive, consumer, medical, and energy industries increasingly turn to additive manufacturing for product innovation and supply chain obstacles while awaiting high performance and shorter lead times. Quickparts believes it will be able to efficiently scale its AM operations thanks to the CO-AM platform integration, which links to a broad range of technologies and incorporates with its current production infrastructures.

“The open architecture of CO-AM enables manufacturers to work with their preferred tools, giving them the flexibility to build a process that is tailored to their business,” added Schueren.

Additive manufacturing and on-demand production software platforms

Previously, on-demand manufacturing software provider 3YOURMIND and material experts Arkema introduced ‘Easy 3D’, a digital platform that connects Arkema clients to vendors of Arkema materials. Engineers who employ this platform have access to Arkema’s potent material suggestions, which assist them in making decisions and enhancing part applications for on-demand manufacturing. Furthermore, by creating an extensive network that enables customers to purchase parts employing high-quality materials, technologies, and additive manufacturing suppliers, this innovative platform capitalizes on 3YOURMIND’s digital expertise.

Furthermore, automated post-processing systems developer PostProcess Technologies and metal 3D printing service Enable Manufacturing, a metal 3D printing service, both launched 3D printing software platforms to take additive manufacturing and post-processing to the next level. PostProcess announced the availability of its CONNECT3D platform, a novel addition to the company’s hardware, chemistry, and software stack that aims to fill lengthy gaps in the post-printing market. Meanwhile, Enable created EnableChain, a custom software package intended to automate and expedite the shipment of metal parts manufactured using its Additive Casting technology.

Follow this link for all the 3D Printing Trends 2023.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows the CO-AM platform logo. Image via Materialise.