PTC’s annual user conference in Boston’s Seaport District had one unifying message to attendees this year: Digital Transformation is coming.

From augmented reality and industrial internet of things (IIOT) demonstrations, to a partner exhibition and interactive cybersecurity displays, this year focused on inbound technologies and their importance to our connected future.

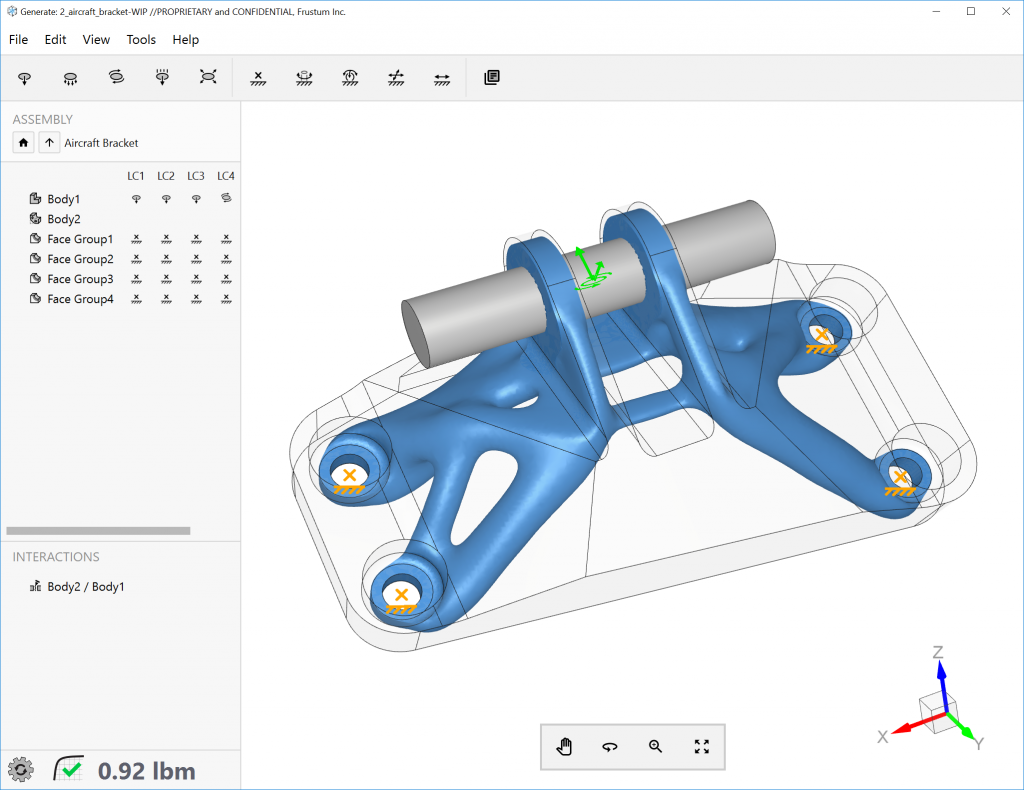

Select talks focused on additive manufacturing and generative design; a technology highlighted during CEO Jim Heppelman’s keynote thanks to PTC’s acquisition of Frustum late in 2018. Frustum is now part of PTC’s Reality Lab, where technologies are incubated in preparation for a full commercial launch.

For background, Frustum’s core technology was an iterative design and modeling workflow that allowed users to apply lattice structures, topology optimization, and various geometric manufacturing constraints to a part design. The software also uses machine learning trained on the finite element analysis (FEA) results of potential part designs to reduce the computational rigor required to converge on an optimal design.

The five levels of generative design

Frustum’s founder and CEO, Jesse Coors-Blankenship, is now a Senior VP of Technology and gave attendees a proper overview and update during his presentation entitled “The Generative Era of CAD”. Jesse presented a systematic framework for thinking about levels of autonomy in generative design. Each level is defined by an innovation starting with iterative and feature-oriented topology optimization for level zero. Level one is defined by manufacturable designs and an interactive process between designer and software. Level two is considered partially generative and moves design evaluation and iteration to a cloud architecture. Level three then applies AI with simulated evolution of designs while applying various multiphysics simulations (electromagnetic and thermal as examples beyond mechanical simulation). The fourth level is deemed highly generative, a machine learning-enabled iterative process that takes into account systems level considerations. In its ultimate form, the fifth level involves natural language processing for seamless interaction between designer and a fully autonomous design platform.

Integration with PTC

As far as integration into the PTC software offering, the generative design capability will be released in conjunction with Creo v7 as an added-cost capability when the new version releases in March 2019. This version would be designated a level three generative capability at release thanks to static linear, thermal, and modal multi-physics capabilities being applied to manufacturable geometries for a part or parts in an assembly. This combination is a main selling point for manufacturers looking to expand design capabilities for 3D printing as well as conventional manufacturing processes.

When considering constraints beyond physical stresses and safety factors, Jesse noted that the intention for PTC’s development of generative design long-term would include an API or similar mechanism for users to input economic, sustainability, and manufacturing considerations into the overall optimization. PTC’s generative design strategy clearly supports CREO as a platform design software that is more accessible to users across experience levels and with a focus on designing for specific manufacturing technologies.

For more of the latest news from related additive manufacturing events, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Visit 3D Printing Jobs to make your next career move.

Featured image shows inside PTC’s LIVEWORX 2019 user conference in Boston’s Seaport District. Photo by Dayton Horvath