Germany-based investment company Koehler Group announced a strategic partnership with Munich-based technical university UnternehmerTUM.

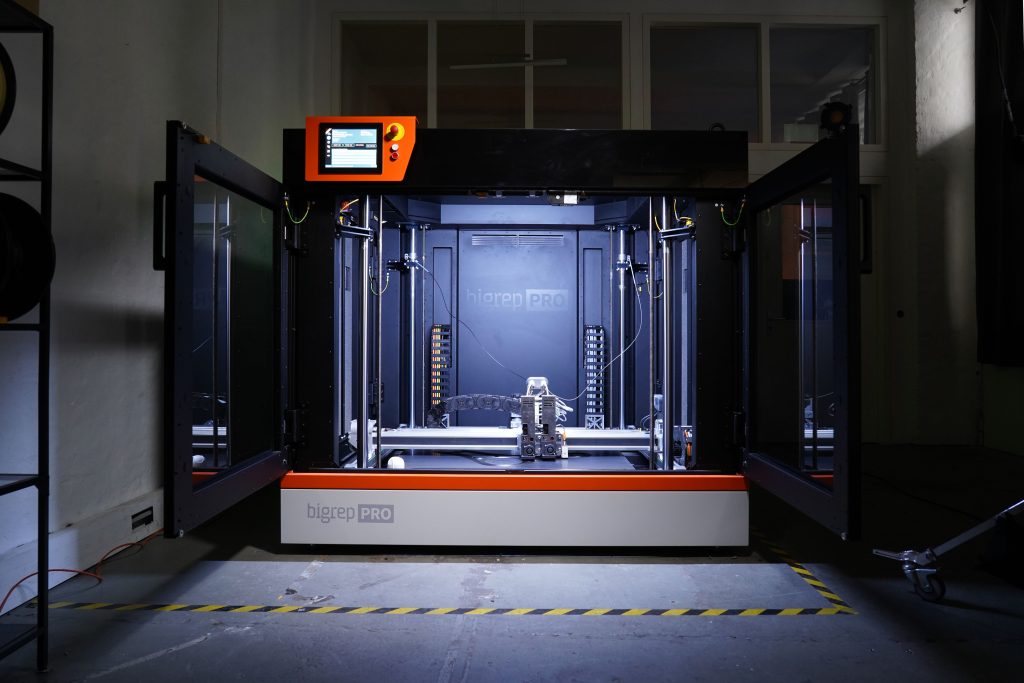

Furthermore, Koehler Invest has loaned a BigRep PRO 3D printer to UnternehmerTUM’s MakerSpace for one year. BigRep is one of the world’s leading large format 3D printing companies, which has the potential to “accelerate innovation and increase flexibility and digitalization in manufacturing processes,” says Koehler Group.

“With the new strategic partnership with UnternehmerTUM, our goal is to support and promote pioneering innovations, particularly in our core business areas of paper and renewable energies. The large format 3D printer from BigRep will prove an invaluable tool for new product innovations from start‐ups,” said Kai Furler, CEO of the Koehler Group.

Enhanced production of prototypes and small series

The BigRep PRO was purchased by the Koehler Group and lent to MakerSpace for free for a year. The system, designed for industrial applications, allows the production of prototypes and larger batches of parts, allowing inventors and developers to create and market technologies more quickly. Previous MakerSpace spinoffs contain Curfboard, which manufactures surf skateboards, Agrilution, which produces vertical farming, and HORYZN, which manufactures unmanned aircraft.

The BigRep PRO allows startups to “explore new grounds and seek answers to some of today’s most pressing questions,” according to the company. The BigRep PRO includes a number of automated functions for the simple, quick, and high-quality manufacturing of large plastic parts made from bio-based and fiber-reinforced materials.

“Product and development cycles are getting shorter and shorter. At the same time, products are becoming increasingly agile, continually improving, and being made ready for the market thanks to fast iterations. Our large‐format solutions for additive production offer the flexibility to print prototypes and molds, e.g. for manufacturing carbon fiber‐reinforced parts, as well as production tools and small series for market launch,” added, Dr. Sven Thate, Managing Director of BigRep.

Additive manufacturing benefitting from strategic partnerships

Recently, Elementum 3D, a Colorado-based additive manufacturing material developer, purchased the NXG XII 600 and signed a material development agreement with SLM Solutions, a metal 3D printer manufacturer. The collaboration expands the use of additive manufacturing, raises awareness of Elementum 3D materials, and allows SLM Solutions to rapidly expand the material portfolio for the NXG XII 600. Elementum 3D’s high-performance alloys will be accessible on SLM technology as early as 2023.

Furthermore, post-printing solutions provider PostProcess and leading 3D printer manufacturer EOS announced a collaborative alliance to provide EOS users with a fully automated and sustainable depowdering solution. The PostProcess Variable Acoustic Displacement (VAD) technology automates the gross depowdering of 3D printed parts, completing the EOS printer product line. According to PostProcess, VAD technology has been successfully used with large industrial customers to process hundreds of SLS powder cakes and thousands of parts in production environments.

Previously, AML3D, an Australian metal 3D printing specialist, announced an extension of its partnership with leading aerospace manufacturing company Boeing. Boeing tasked AML3D earlier this year with 3D printing aluminum prototype aeroplane parts as part of an intensive testing program in which they were assessed against the requirements of AS9100D quality assurance for ‘fly’ parts. Building on this contract, it has been agreed to broaden the scope of the project to include the supply of additional 3D printed components, increasing the deal’s value by 150%.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows Kai Furler, CEO of the Koehler Group, symbolically pressing the start button for the development of future-oriented prototypes on the BigRep PRO 3D printer in MakerSpace. Image via Koehler Group.