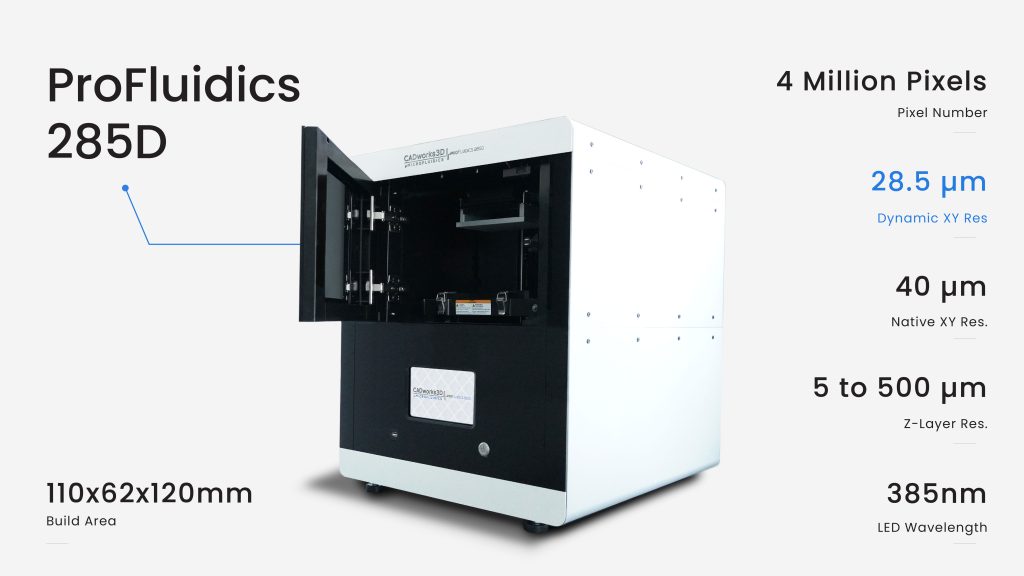

CADworks3D, a Canadian 3D printer manufacturer and 3D material developer, has brought forward a cutting-edge DLP 3D printer designed especially for microfluidic applications: the ProFluidics 285D. This revolutionary machine reshapes the way researchers think about microfluidic device fabrication and offers an alternative to conventional fabrication techniques, which are notoriously expensive, time-consuming, and labor-intensive.

Instead, the ProFluidics 285D opens up workflows that are streamlined and easy to implement. It is a multi-purpose machine whereby this one 3D printer can produce a variety of microfluidic devices such as clear devices with encapsulated features, master molds for PDMS devices, and biocompatible devices or structures. Together with CADworks3D’s line of 3D material, researchers can reliably produce 100µm channels, and smaller depending on the device’s design.

“CADworks3D’s ultimate goal is to empower microfluidic researchers by providing them with an accessible 3D printing system that is affordable, easy-to-adopt, and versatile – all without sacrificing high-resolution print quality.”

How Does Standard DLP 3D Printing Work?

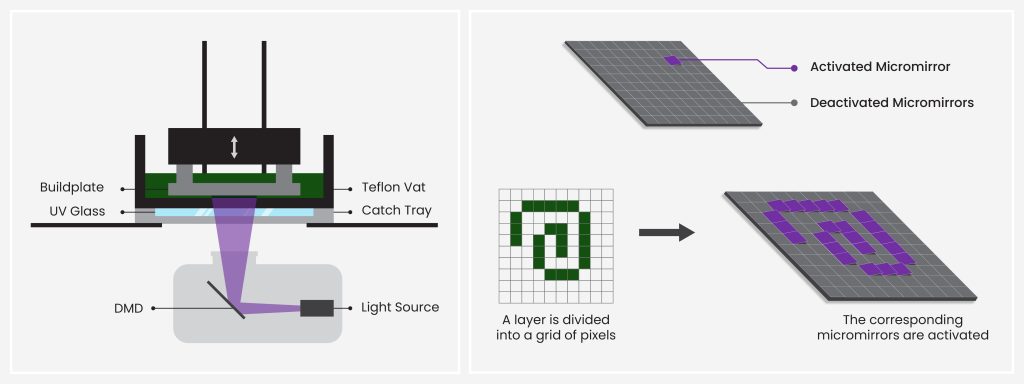

Digital Light Processing (DLP) is one of the most common technologies used in vat polymerization 3D printing, or resin 3D printing, that translates digital computer assisted design (CAD) into usable 3D objects. The backbone of this technology is a digital projector that beams UV light onto an array of microscopic mirrors called a Digital Micromirror Device (DMD). These mirrors reflect the UV light onto a layer of photosensitive resin and cause it to cure in the shape of the object being printed. This repeats layer-by-layer until an entire object is created. (See Figure B, Left Side).

A CAD file is sliced into layers, similar to the slice of a CT scan. Each layer is further divided into a grid of pixels, with each pixel corresponding to an individual mirror in the DMD. While printing a layer, the projector activates the mirrors corresponding to the pixels required to build the CAD file. When the mirrors are activated, they reflect UV light onto the liquid resin and cure it precisely on the pixels. When mirrors are deactivated, they do not shine, leaving those areas of resin uncured. (See Figure B, Right Side) The projected pixel size is expressed in micrometers (µm) and coincides with the XY resolution listed on a printer’s technical specifications.

How the ProFluidics 285D Exceeds Standard DLP 3D Printing:

Print Exceptionally Smooth Curves and Shapes

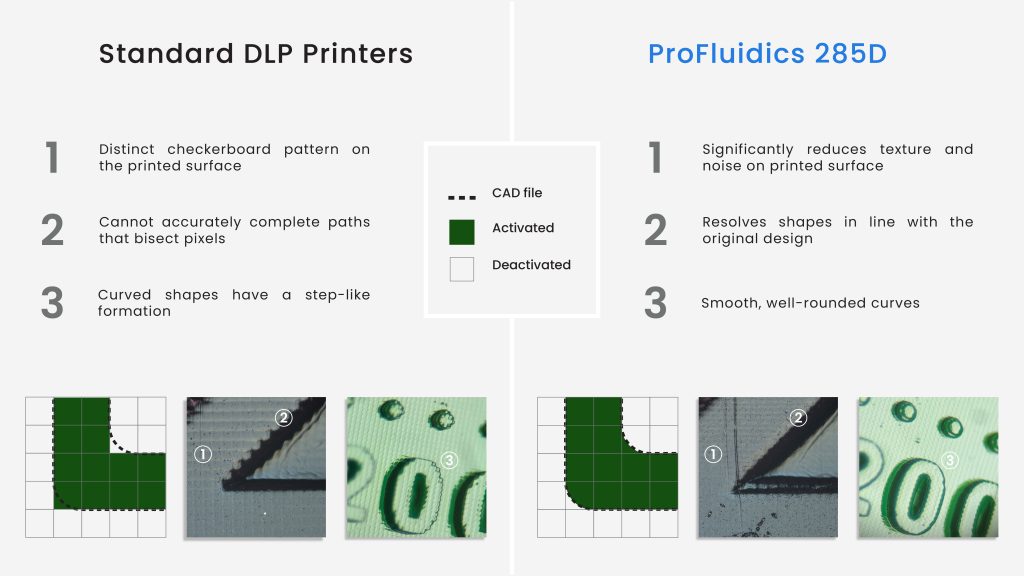

What happens when parts of the CAD file bisects pixels? Standard DLP printers will evaluate how much of the design covers a given pixel and use a binary rounding function to either activate or deactivate the entire pixel during printing. The result is a device with a discernible checkered pattern on its surface and a step-like curve (See Figure C, Left Side). Often, the device ends up deviating from the original CAD file.

The ProFluidics 285D addresses this issue with its dynamic pixel advantage. Delivering a dynamic XY resolution of 28.5µm, the ProFluidics 285D offers significant improvements in accurately resolving design features – even those that bisect pixels. Printed devices closely resemble the intended design, and the occurrence of cube patterns and noise is minimized when compared to existing available platforms (See Figure C, Right Side). With this technology, the ProFluidics 285D can successfully print features with 180-degree turns, complex serpentine channels, and other intricate geometries.

Application 1: Clear Encapsulated Devices

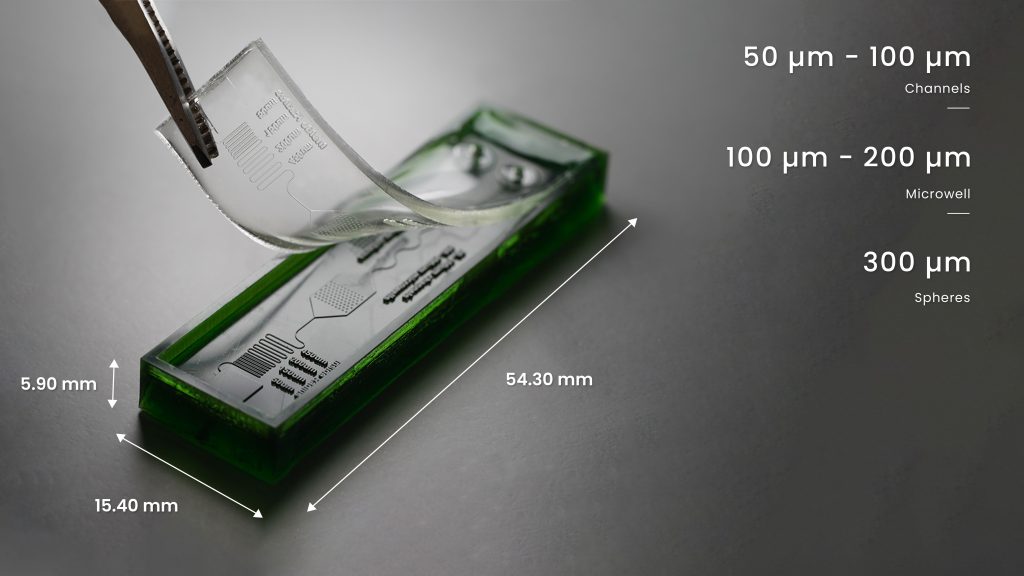

The ProFluidics 285D can produce different categories of microfluidic devices, the first being clear devices with encapsulated channels and features.

The viability and scale of these encapsulated channels are crucial aspects of these devices, and with CADworks3D’s Clear Microfluidics Resin, the ProFluidics 285D excels. Devices can be fabricated in just one print job without assembling multiple parts, and encapsulated channels printed in the XY can be as fine as 80μm. Researchers can also create more novel designs incorporating variations of Z heights, such as helix coils (See Figure D).

Post-processing is a quick and easy procedure. Depending on the device’s height, the entire process of printing a ready-to-use device can be completed in just over an hour. No surface coating or polishing is needed to achieve optical transparency, eliminating several, often tedious, post-processing steps required by other methods and materials. The Clear Microfluidics Resin is inert under fluorescent lighting, making it suitable for microscopy and imaging.

Application 2: Master Mold for PDMS Devices

When using traditional techniques like photolithography, the fabrication of master molds is expensive, time-consuming, and arduous. The ProFluidics 285D moves the fabrication of master molds from the clean room and brings them to the bench side, thereby significantly accelerating the process. Researchers are given the ability to 3D print, clean, and cure a master mold in just a few hours, and within one working day, a PDMS device can be cast and ready for bonding to a substrate.

With CADworks3D’s Master Mold for PDMS Device Resin, you can print molds with channel widths as small as 50um. The printed molds demonstrate exceptional detail and smoothness with an average measured Ra value of 0.18µm. These printed master molds are very durable, can withstand the temperatures needed to cast and cure PDMS in an oven, and can be used repeatedly to cast hundreds of PDMS devices from one master.

The photopolymer resin has been formulated so that there is no need for any release agents, coatings and other pre-treatment processes for a successful clean PDMS cast. Furthermore, the printed master does not leech any chemicals onto the casted PDMS and so the resulting PDMS devices retain their biocompatible properties.

Application 3: Biocompatible Devices & Structures

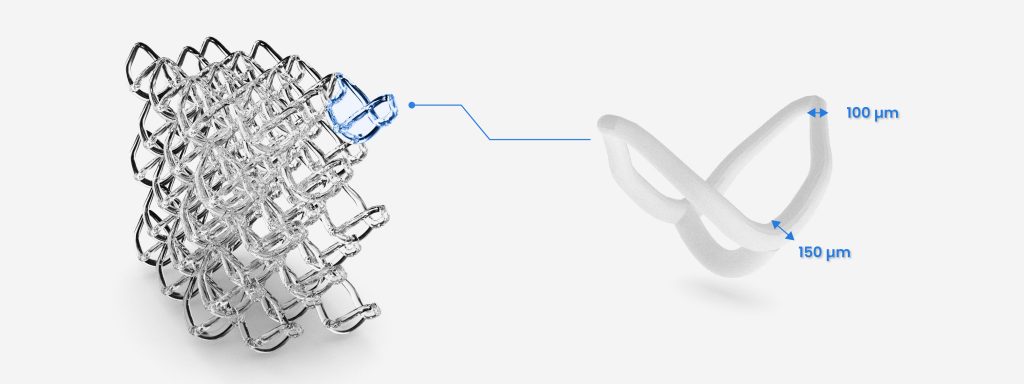

Expanding on the topic of biocompatible devices, the ProFluidics 285D operates on an open material system, allowing users the ability to print with 3rd party materials. It houses a projector equipped with a 385nm LED light source, and as such, the ProFluidics 285D can print with several biocompatible 3D resins available on the market for uses such as bioscaffolds (See Figure F).

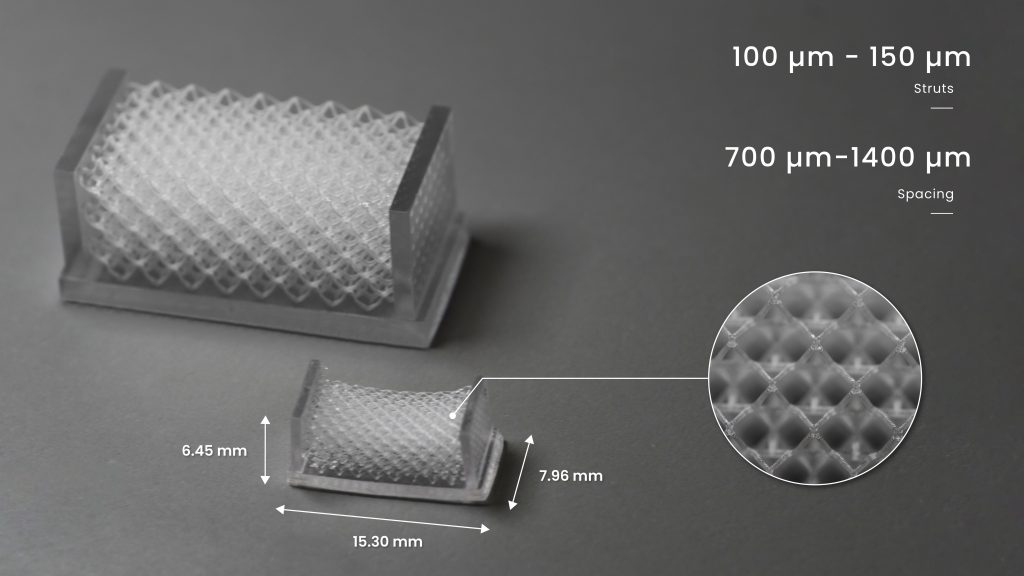

A unique characteristic of 3D printing bioscaffolds is the ability to print a staggered lattice (See Figure G). This creates a more random structure that enables cells to grow along the bias and facilitate a more uniform growth distribution. Using the Detax Freeprint Ortho Resin as an example, the ProFluidics 285D is able to print bioscaffolds in just over an hour with struts as fine as 100µm and spacings that range between 700µm-1400µm.

Made to Empower Microfluidics Research

The existing 3D marketplace typically offers solutions for microfluidics that are repurposed from other industries and as a result there is often a gap or a complete mismatch between a researcher’s needs and a printer’s capabilities. Microfluidic devices call for printed features that are sub-100 microns, and many prevailing platforms fail to provide the scale or quality necessary.

CADworks3D’s ProFluidics 285D and materials have been formulated solely with microfluidic applications in mind. Together, they offer a complete package to researchers, meeting the demand for finer printed features with minimum channel sizes of 80µm and 50µm for encapsulated and open channels, respectively. It empowers new, innovative workflows that save researchers on time, labor, and monetary costs. It becomes possible to produce three to five devices in just a few hours, where at 5g per device, the cost is approximately US$2.05 – US$2.55. Compared to traditional fabrication methods or the cost of outsourcing fabrication to third-party 3D printing services, the benefits of working with a complete in-house 3D printing platform become apparent.

Featured image shows The ProFluidics 285D. Photo via CADworks3D.